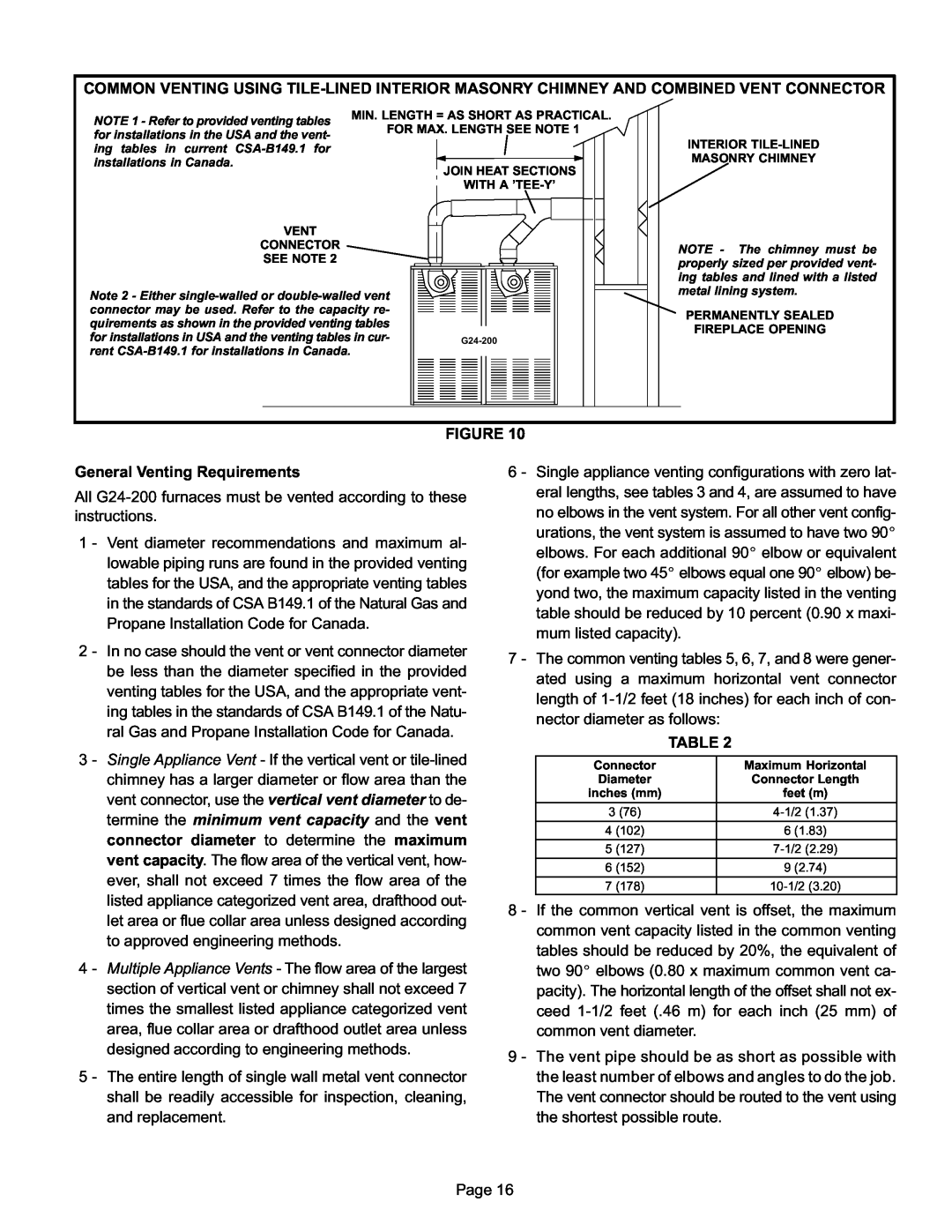

COMMON VENTING USING TILE−LINED INTERIOR MASONRY CHIMNEY AND COMBINED VENT CONNECTOR

NOTE 1 − Refer to provided venting tables | MIN. LENGTH = AS SHORT AS PRACTICAL. | ||

FOR MAX. LENGTH SEE NOTE 1 | |||

for installations in the USA and the vent- | |||

| INTERIOR TILE−LINED | ||

ing tables in current CSA−B149.1 for |

| ||

| MASONRY CHIMNEY | ||

installations in Canada. |

| ||

| JOIN HEAT SECTIONS | ||

|

| ||

|

| WITH A ’TEE−Y’ | |

VENT |

|

| |

CONNECTOR |

| NOTE − The chimney must be | |

SEE NOTE 2 |

| ||

| properly sized per provided vent- | ||

|

| ||

|

| ing tables and lined with a listed | |

Note 2 − Either | metal lining system. | ||

| |||

connector may be used. Refer to the capacity re- | PERMANENTLY SEALED | ||

quirements as shown in the provided venting tables | |||

FIREPLACE OPENING | |||

for installations in USA and the venting tables in cur- | |||

G24−200 | |||

rent CSA−B149.1 for installations in Canada.

FIGURE 10

General Venting Requirements

All G24−200 furnaces must be vented according to these instructions.

1 − Vent diameter recommendations and maximum al- lowable piping runs are found in the provided venting tables for the USA, and the appropriate venting tables in the standards of CSA B149.1 of the Natural Gas and Propane Installation Code for Canada.

2 − In no case should the vent or vent connector diameter be less than the diameter specified in the provided venting tables for the USA, and the appropriate vent- ing tables in the standards of CSA B149.1 of the Natu- ral Gas and Propane Installation Code for Canada.

3 − Single Appliance Vent − If the vertical vent or

4 − Multiple Appliance Vents − The flow area of the largest section of vertical vent or chimney shall not exceed 7 times the smallest listed appliance categorized vent area, flue collar area or drafthood outlet area unless designed according to engineering methods.

5 − The entire length of single wall metal vent connector shall be readily accessible for inspection, cleaning, and replacement.

6 − Single appliance venting configurations with zero lat- eral lengths, see tables 3 and 4, are assumed to have no elbows in the vent system. For all other vent config- urations, the vent system is assumed to have two 90_ elbows. For each additional 90_ elbow or equivalent (for example two 45_ elbows equal one 90_ elbow) be- yond two, the maximum capacity listed in the venting table should be reduced by 10 percent (0.90 x maxi- mum listed capacity).

7 − The common venting tables 5, 6, 7, and 8 were gener- ated using a maximum horizontal vent connector length of

| TABLE 2 | |

|

|

|

Connector |

| Maximum Horizontal |

Diameter |

| Connector Length |

inches (mm) |

| feet (m) |

|

|

|

3 (76) |

| 4−1/2 (1.37) |

|

|

|

4 (102) |

| 6 (1.83) |

|

|

|

5 (127) |

| 7−1/2 (2.29) |

|

|

|

6 (152) |

| 9 (2.74) |

|

|

|

7 (178) |

| 10−1/2 (3.20) |

8 − If the common vertical vent is offset, the maximum common vent capacity listed in the common venting tables should be reduced by 20%, the equivalent of two 90_ elbows (0.80 x maximum common vent ca- pacity). The horizontal length of the offset shall not ex- ceed

9 − The vent pipe should be as short as possible with the least number of elbows and angles to do the job. The vent connector should be routed to the vent using the shortest possible route.

Page 16