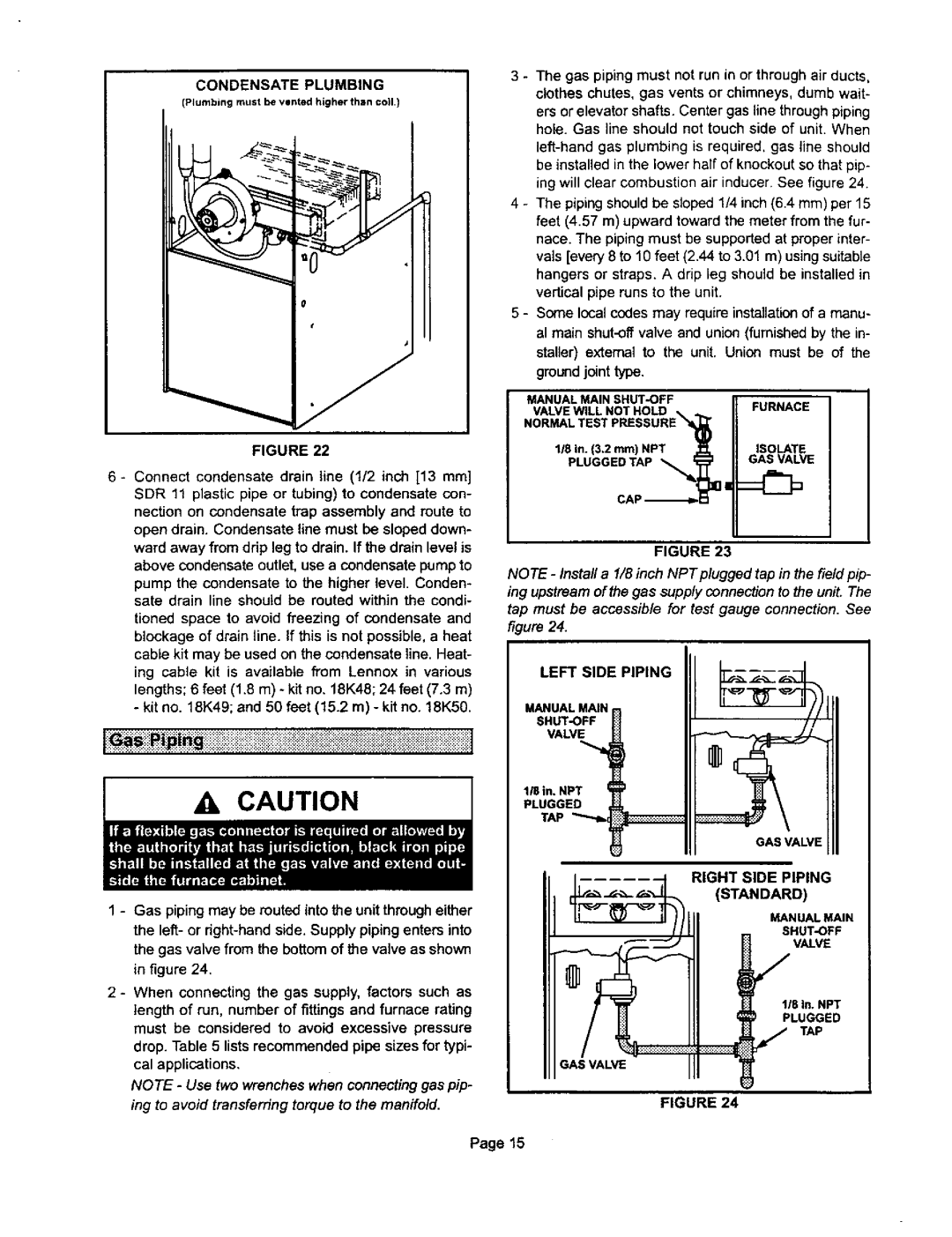

CONDENSATE PLUMBING

(Plumbing must be vented higher than coll.)

3 - The gas piping must not run in or through air ducts, clothes chutes, gas vents or chimneys, dumb wait-

ers or elevator shafts. Center gas line through piping hole. Gas line should not touch side of unit. When

4 - The piping should be sloped 1/4 inch (6.4 mm) per 15 feet (4.57 m) upward toward the meter from the fur- nace. The piping must be supported at properinter- vals [every 8to 10 feet (2.44 to 3.01 m) using suitable hangers or straps. A drip leg should be installed in vertical pipe runs to the unit.

5 - Some local codes may require installationof a manu- al main

groundjoint type,

FIGURE 22

6- Connect condensate drain line (1/2 inch [13 mm] SDR 11 plastic pipe or tubing) to condensate con- nection on condensate trap assembly and route to open drain. Condensate line must be sloped down- ward away from drip leg to drain. If the drain level is above condensate outlet, use a condensate pump to

pump the condensate to the higher level. Conden- sate drain line should be routed within the condi-

tioned space to avoid freezing of condensate and blockage of drain line. If this is not possible, a heat cable kit may be used on the condensate line. Heat- ing cable kit is available from Lennox in various lengths; 6 feet (1.8 m) - kit no. 18K48; 24 feet (7.3 m) - kit no. 18K49; and 50 feet (15.2 m) - kit no. 18K50.

1 - Gas piping may be muted into the unitthrough either the left- or

2- When connecting the gas supply, factors such as length of run, number of fittings and furnace rating must be considered to avoid excessive pressure drop. Table 5 lists recommended pipe sizes for typi- cal applications.

NOTE - Use two wrenches when connecting gas pip- ing to avoid transferring torque to the manifold.

II

FIGURE 23

NOTE - Install a 1/8 inch NPTplugged tap in the field pip ing upstream ofthe gas supplyconnection to the unit. The tap must be accessible for test gauge connection. See figure 24.

LEFT SIDE PIPING

MANUAL MAIN

VALVE

1/8 in. NPT PLUGGED TAP

GAS VALVE

.... --I, RIGHT SIDE PIPING

_(.=.__=.-,_t_ (STANDARD)

118In. NPT PLUGGED

..........................j,AP

GAS VALVE

FIGURE 24

Page 15