Inches (mm) |

| 9 |

|

|

| ||

|

|

|

|

| |||

|

|

| I '10" | _, EXHAUST | |||

|

|

|

| VENT | |||

Front | View |

| = _ | NOTE - Enclosed ex_us_ pipe _s | |||

[INTAKE | insuleted w;th _F2 i,_Ch(13 ram) | ||||||

|

| ||||||

|

| foam insu_abon If in_al(ear_ ex- | |||||

|

| 34 | VENT | hsusl | I_pes am reversed, sl=land | ||

|

|

| r_move | foam | instJlat_ot_ and | ||

|

|

|

| ||||

|

|

|

| vent mr=st be | insulated | ||

|

| Ii |

| teat)ply to OUmr vent Exhaust | |||

Side | View |

| 4 |

|

|

| |

|

|

|

|

| |||

USTVENT

o

iNTAKE

VENT

E

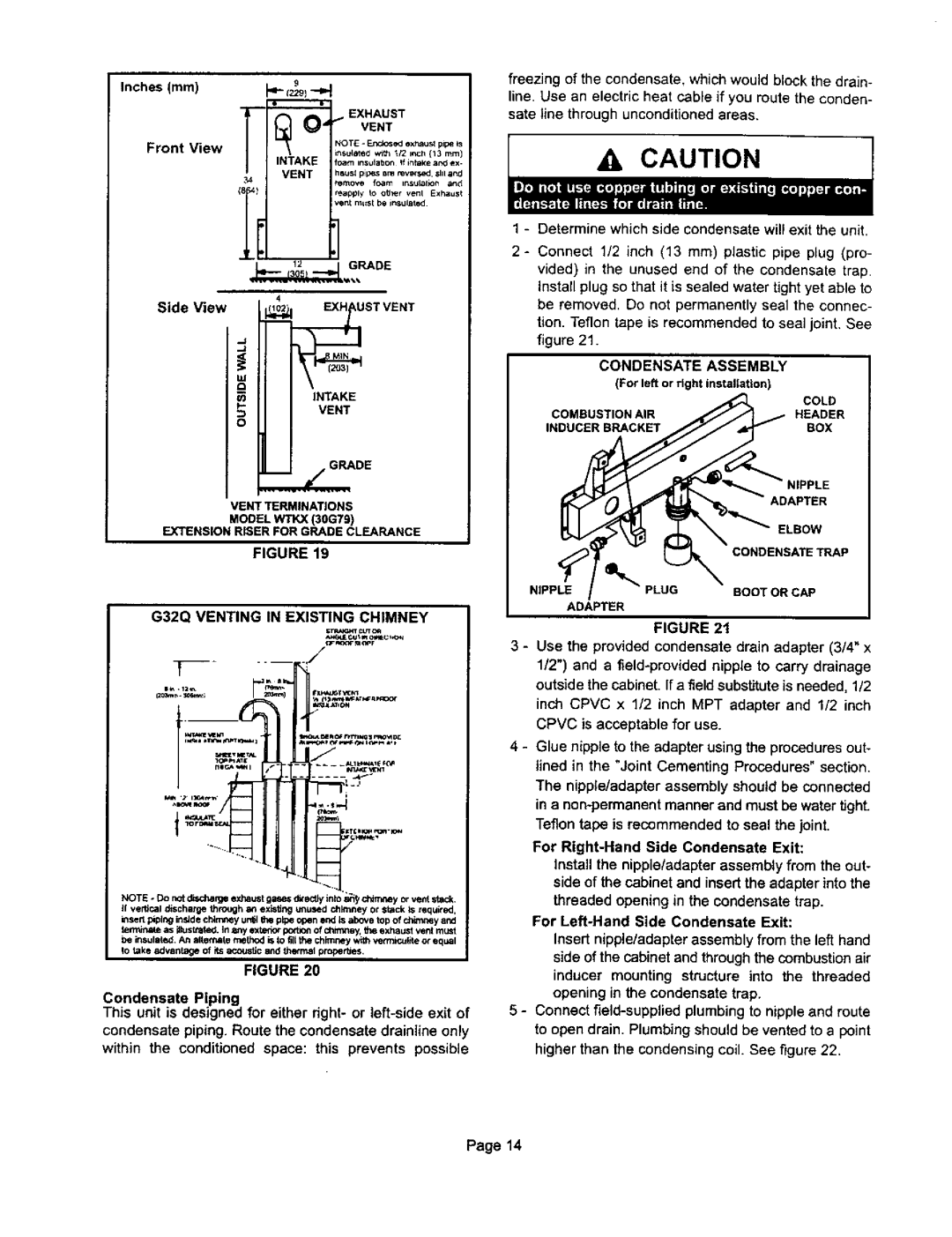

VENT TERMINATIONS

MODEL WTKX (30GT9)

EXTENSION RISER FOR GRADE CLEARANCE

FIGURE 19

G32Q VENTING IN EXISTING CHIMNEY

NOTE - Do not dischal_e exhaust gases dit ently | into | or vent stack. | |

II ventCal discharge through at, ex_6ng unused | chimney | or stack ts require<J, | |

i_sertpipingintgde chlm,'.eyurdilthe pipe open end Is above top of _y | and | ||

termimlte as iltusttstad. I. any extedor po(tlon of ¢ilrmney, the exhaust vent must

be insulated.An alternatemethodis to flit the chimneywith vetrmc.ulitoor equal

to take advantage of its acoustic and thermal properties,

FIGURE 20

Condensate Piping

This unit is designed for either right- or

condensate piping. Route the condensate drainiine only within the conditioned space: this prevents possible

freezing of the condensate, which would block the drain- line. Use an electric heat cable if you route the conden- sate line through unconditioned areas.

A CAUTION

1 - Determine which side condensate will exit the unit.

2- Connect 1/2 inch (13 mm) plastic pipe plug (pro- vided) in the unused end of the condensate trap. Install plug so that it is sealed water tight yet able to be removed. Do not permanently seal the connec- tion. Teflon tape is recommended to seal joint. See figure 21.

CONDENSATE | ASSEMBLY |

(For left or rightinstallation) | |

| COLD |

COMBUSTION AIR | HEADER |

INDUCER BRACKET | BOX |

ADAPTER

ELBOW

CONDENSATE TRAP

NIPPLEBOOTORCAP ADAPTER

FIGURE 2t

3 - Use the provided condensate drain adapter (3/4" x

1/2") and a

4 - Glue nipple to the adapter using the procedures out- lined in the "Joint Cementing Procedures" section. The nipple/adapter assembly should be connected in a

For Right-Hand Side Condensate Exit:

Install the nipple/adapter assembly from the out- side of the cabinet and insert the adapter intothe threaded opening in the condensate trap.

For

Insert nipple/adapterassembly from the left hand side of the cabinet and through the combustion air inducer mounting structure into the threaded opening in the condensate trap.

5 - Connect

Page14