2. Flaring Work and Connection of Piping

1) Flaring work

Main cause for refrigerant leakage is due to defect in the flaring work. Carry out correct flaring work using the following procedure.

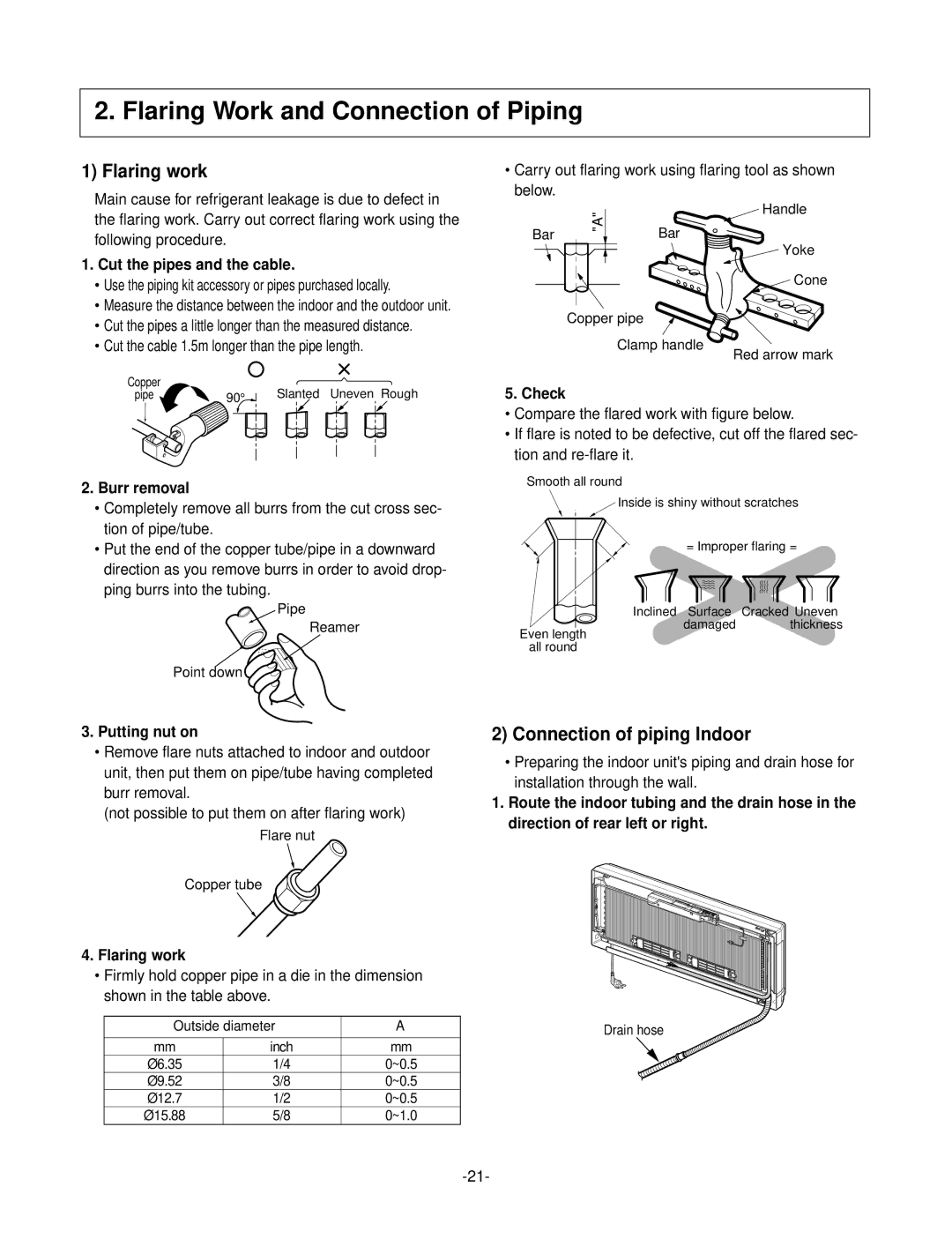

1. Cut the pipes and the cable. |

• Use the piping kit accessory or pipes purchased locally. |

• Measure the distance between the indoor and the outdoor unit. |

•Carry out flaring work using flaring tool as shown below.

| "A" | Handle | |

Bar | Bar | ||

| |||

|

| Yoke | |

|

| Cone |

• Cut the pipes a little longer than the measured distance. |

• Cut the cable 1.5m longer than the pipe length. |

Copper |

| Slanted Uneven Rough |

pipe | 90° |

Copper pipe

Clamp handle ![]()

5. Check

Red arrow mark

2.Burr removal

•Completely remove all burrs from the cut cross sec- tion of pipe/tube.

•Put the end of the copper tube/pipe in a downward direction as you remove burrs in order to avoid drop-

ping burrs into the tubing.

Pipe

Reamer

Point down![]()

3.Putting nut on

•Remove flare nuts attached to indoor and outdoor unit, then put them on pipe/tube having completed burr removal.

(not possible to put them on after flaring work)

Flare nut

Copper tube

4.Flaring work

•Firmly hold copper pipe in a die in the dimension shown in the table above.

Outside diameter | A | |

|

|

|

mm | inch | mm |

Ø6.35 | 1/4 | 0~0.5 |

Ø9.52 | 3/8 | 0~0.5 |

Ø12.7 | 1/2 | 0~0.5 |

Ø15.88 | 5/8 | 0~1.0 |

•Compare the flared work with figure below.

•If flare is noted to be defective, cut off the flared sec- tion and

Smooth all round

Inside is shiny without scratches

= Improper flaring =

Inclined Surface Cracked Uneven

damaged thickness

Even length

all round

2)Connection of piping Indoor

•Preparing the indoor unit's piping and drain hose for installation through the wall.

1.Route the indoor tubing and the drain hose in the direction of rear left or right.

Drain hose