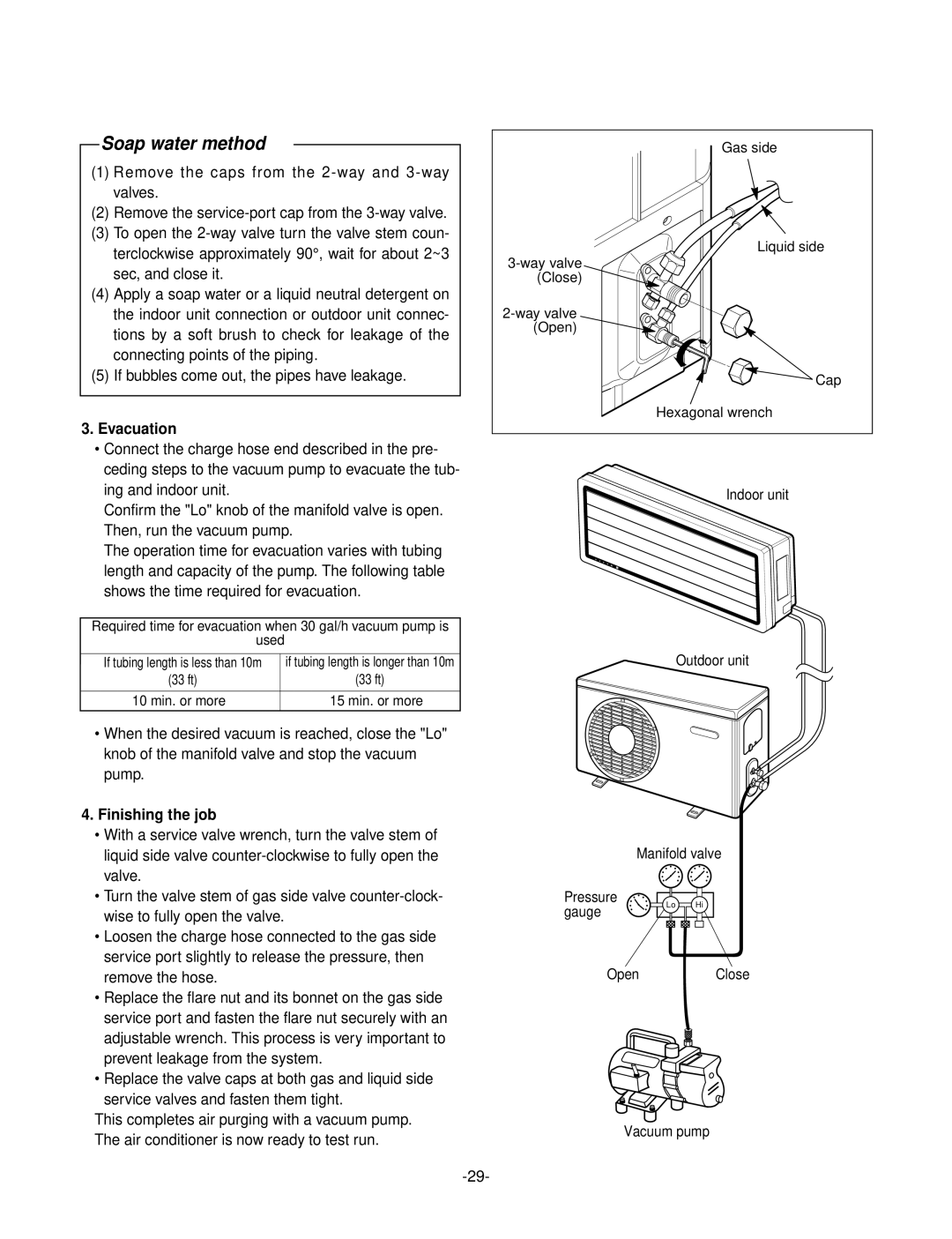

Soap water method

(1)Remove the caps from the

(2)Remove the

(3)To open the

(4)Apply a soap water or a liquid neutral detergent on the indoor unit connection or outdoor unit connec- tions by a soft brush to check for leakage of the connecting points of the piping.

(5)If bubbles come out, the pipes have leakage.

3.Evacuation

•Connect the charge hose end described in the pre- ceding steps to the vacuum pump to evacuate the tub- ing and indoor unit.

Confirm the "Lo" knob of the manifold valve is open. Then, run the vacuum pump.

The operation time for evacuation varies with tubing length and capacity of the pump. The following table shows the time required for evacuation.

Required time for evacuation when 30 gal/h vacuum pump is

used

If tubing length is less than 10m | if tubing length is longer than 10m |

(33 ft) | (33 ft) |

|

|

10 min. or more | 15 min. or more |

|

|

•When the desired vacuum is reached, close the "Lo" knob of the manifold valve and stop the vacuum pump.

4.Finishing the job

•With a service valve wrench, turn the valve stem of liquid side valve

•Turn the valve stem of gas side valve

•Loosen the charge hose connected to the gas side service port slightly to release the pressure, then remove the hose.

•Replace the flare nut and its bonnet on the gas side service port and fasten the flare nut securely with an adjustable wrench. This process is very important to prevent leakage from the system.

•Replace the valve caps at both gas and liquid side service valves and fasten them tight.

This completes air purging with a vacuum pump. The air conditioner is now ready to test run.

Gas side

Liquid side

Cap

Hexagonal wrench

Indoor unit

Outdoor unit

| Manifold valve | |

Pressure | Hi | |

gauge | Lo | |

|

| |

| Open | Close |

Vacuum pump