PIPELINER 18P AWS:

A real workhorse for vertical up welding jobs up to X80 pipe! Lincoln 18P offers low temperature impact properties down to

ADVANTAGE LINCOLN

•Low temperature impact properties down to

•Manufactured to actual lot control. Actual certificates of conformance are available upon request.

TYPICAL APPLICATIONS

•Primarily designed for vertical up fill and cap pass welding of high strength pipe up to and including API

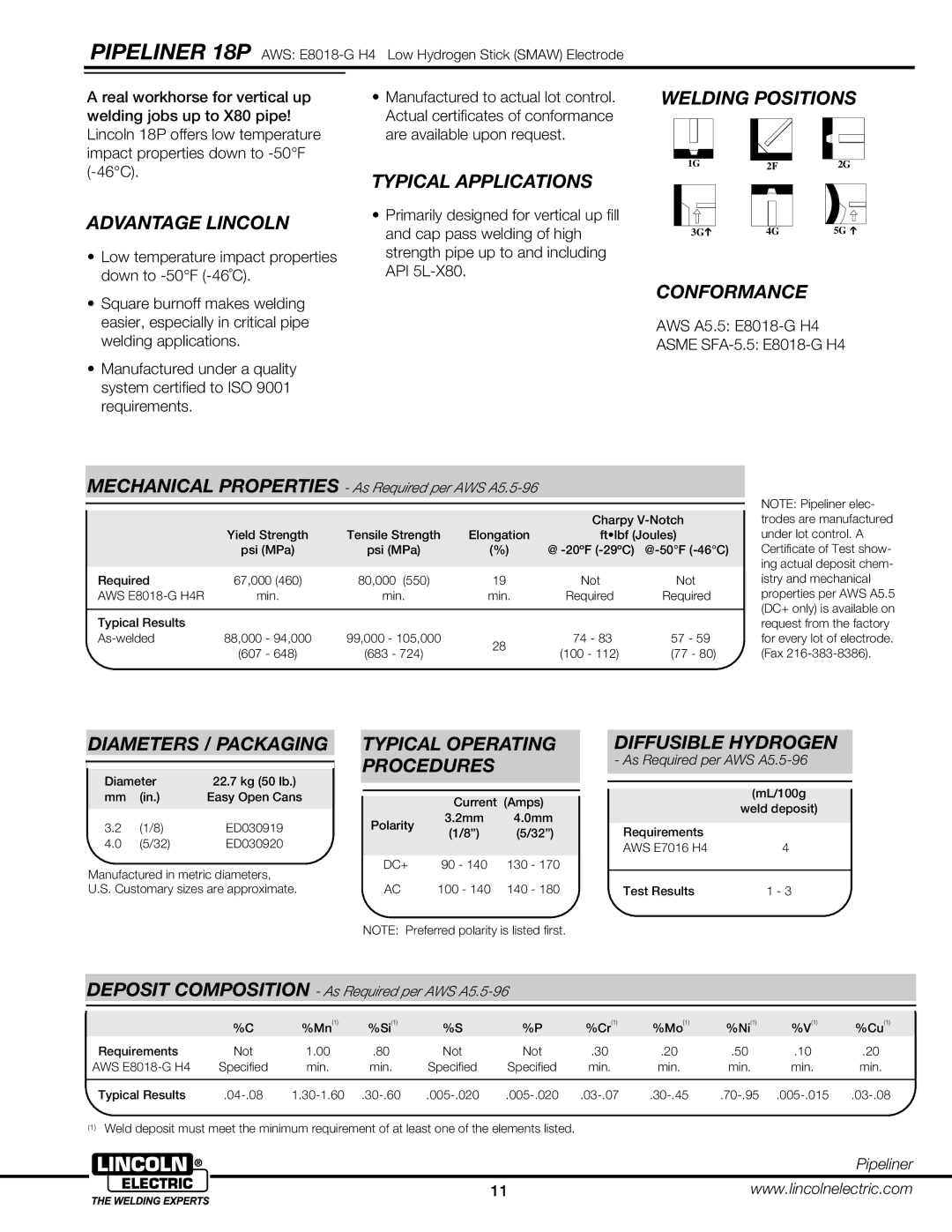

WELDING POSITIONS

1G | 2F | 2G |

3G | 4G | 5G ➔ |

➔ |

|

•Square burnoff makes welding easier, especially in critical pipe welding applications.

•Manufactured under a quality system certified to ISO 9001 requirements.

MECHANICAL PROPERTIES - As Required per AWS A5.5-96

CONFORMANCE

AWS A5.5: E8018-G H4

ASME SFA-5.5: E8018-G H4

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Charpy | |

| Yield Strength | Tensile Strength | Elongation | ft•lbf (Joules) | ||

| psi (MPa) | psi (MPa) | (%) | @ | ||

|

|

|

|

|

| |

Required | 67,000 (460) | 80,000 (550) | 19 | Not | Not | |

AWS | min. | min. | min. | Required | Required . | |

|

|

|

|

|

|

|

Typical Results |

|

|

|

|

|

|

88,000 | - 94,000 | 99,000 - 105,000 | 28 | 74 - 83 | 57 - 59 . | |

| (607 | - 648) | (683 - 724) | (100 - 112) | (77 - 80) . | |

|

| |||||

NOTE: Pipeliner elec- trodes are manufactured under lot control. A Certificate of Test show- ing actual deposit chem- istry and mechanical properties per AWS A5.5 (DC+ only) is available on request from the factory for every lot of electrode. (Fax

DIAMETERS / PACKAGING

|

|

|

|

|

|

Diameter | 22.7 kg (50 lb.) | |

mm | (in.) | Easy Open Cans |

|

|

|

3.2 | (1/8) | ED030919 |

4.0 | (5/32) | ED030920 |

Manufactured in metric diameters, U.S. Customary sizes are approximate.

TYPICAL OPERATING PROCEDURES

Current (Amps)

3.2mm 4.0mm

Polarity

(1/8”) (5/32”)

DC+ 90 - 140 130 - 170

AC | 100 - 140 140 - 180 |

NOTE: Preferred polarity is listed first.

DIFFUSIBLE HYDROGEN

- As Required per AWS A5.5-96

|

|

|

|

|

|

|

|

|

|

|

|

| (mL/100g |

|

|

|

| weld deposit) |

|

|

|

|

|

|

|

| Requirements |

|

|

|

| AWS E7016 H4 | 4 |

|

|

|

|

|

|

|

| Test Results | 1 - 3 |

|

DEPOSIT COMPOSITION - As Required per AWS A5.5-96

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| %C | %Mn(1) | %Si(1) | %S | %P | %Cr(1) | %Mo(1) | %Ni(1) | %V(1) | %Cu(1) |

| Requirements | Not | 1.00 | .80 | Not | Not | .30 | .20 | .50 | .10 | .20 |

| AWS | Specified | min. | min. | Specified | Specified | min. | min. | min. | min. | min. |

|

|

|

|

|

|

|

|

|

|

|

|

| Typical Results |

(1)Weld deposit must meet the minimum requirement of at least one of the elements listed.

Pipeliner

11 | www.lincolnelectric.com |