PIPELINER 8P+ AWS:

Here’s an electrode that makes short work of even the most challenging high silicon pipe applications! Pipeliner 8P+ is an outstanding choice for API

–formulated to carry and deposit weld metal in difficult vertical down

ADVANTAGE LINCOLN

•Manufactured to metric electrode diameters – use anywhere in the world.

•Fill and Cap Consistency – Approved manufacturing sites deliver industry- leading consistency in composition and arc action.

•Excellent Resistance to Porosity – Repeated

•High Stacking Efficiency – Formulated to carry and deposit weld metal in difficult vertical down

•Exceptional mechanical properties – Consistent

•Manufactured to actual lot control. Actual certificates of conformance are available upon request.

TYPICAL APPLICATIONS

•Typical applications include high- yield pipe steels.

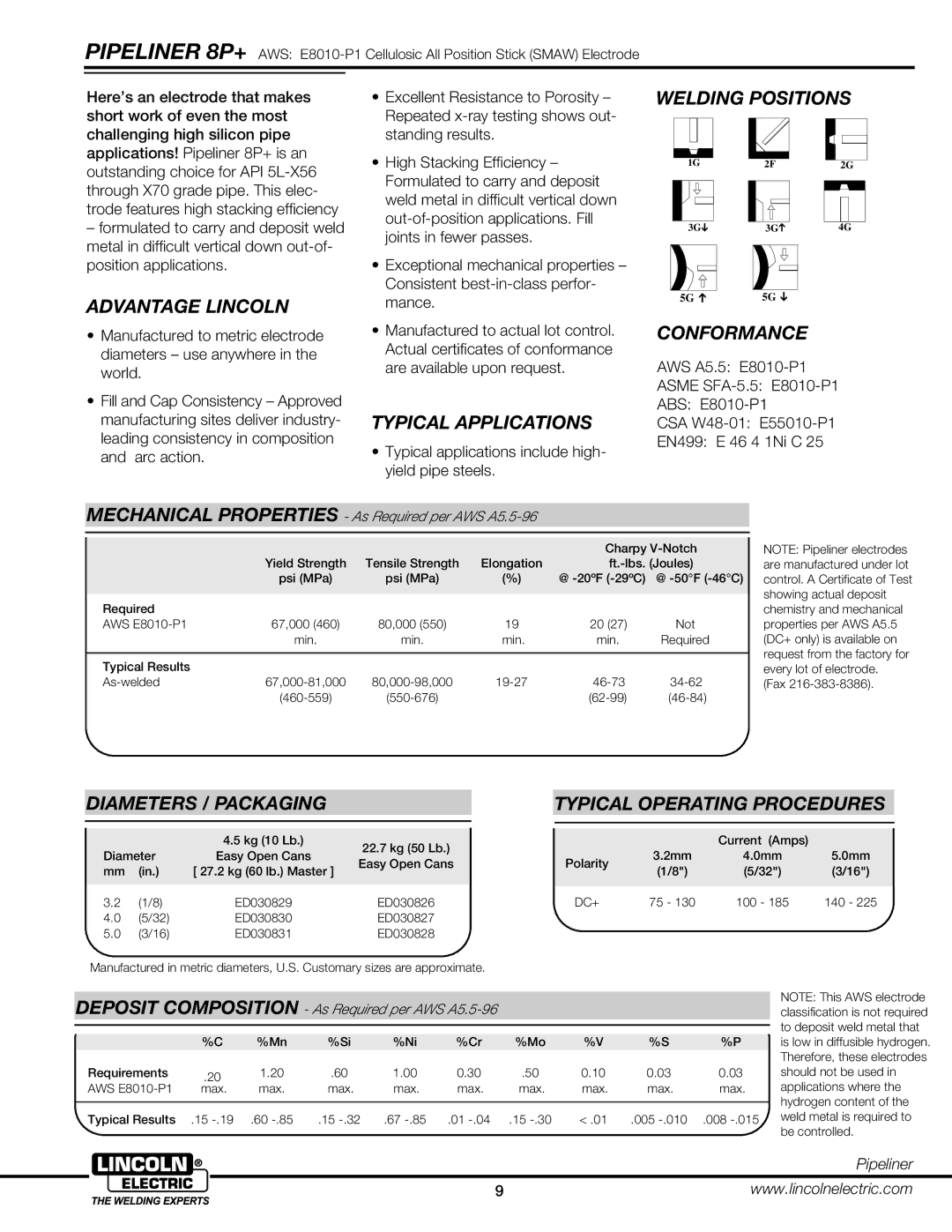

WELDING POSITIONS

1G | 2F | 2G |

3G➔ | 3G➔ | 4G |

5G | ➔ | 5G | ➔ |

CONFORMANCE

AWS A5.5:

ASME

ABS:

CSA

EN499: E 46 4 1Ni C 25

MECHANICAL PROPERTIES - As Required per AWS A5.5-96

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Charpy |

| |

|

| Yield Strength | Tensile Strength | Elongation |

| ||

|

| psi (MPa) | psi (MPa) | (%) | @ | @ |

|

|

|

|

|

|

|

|

|

| Required |

|

|

|

|

|

|

| AWS | 67,000 (460) | 80,000 (550) | 19 | 20 (27) | Not . |

|

|

| min. | min. | min. | min. | Required |

|

|

|

|

|

|

|

|

|

| Typical Results |

|

|

|

|

|

|

|

| ||||||

|

|

|

| ||||

NOTE: Pipeliner electrodes are manufactured under lot control. A Certificate of Test showing actual deposit chemistry and mechanical properties per AWS A5.5 (DC+ only) is available on request from the factory for every lot of electrode.

(Fax

| DIAMETERS / PACKAGING |

|

|

|

| TYPICAL OPERATING PROCEDURES |

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4.5 kg (10 Lb.) | 22.7 kg (50 Lb.) |

|

|

|

|

|

| Current (Amps) |

|

|

| Diameter | Easy Open Cans |

|

|

|

|

| 3.2mm | 4.0mm | 5.0mm |

| ||

| Easy Open Cans |

|

|

|

| Polarity |

| ||||||

| mm | (in.) | [ 27.2 kg (60 lb.) Master ] |

|

|

|

| (1/8") | (5/32") | (3/16") |

| ||

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3.2 | (1/8) | ED030829 | ED030826 |

|

|

|

| DC+ | 75 - 130 | 100 - 185 | 140 - 225 |

|

| 4.0 | (5/32) | ED030830 | ED030827 |

|

|

|

|

|

|

|

|

|

| 5.0 | (3/16) | ED030831 | ED030828 |

|

|

|

|

|

|

|

|

|

Manufactured in metric diameters, U.S. Customary sizes are approximate.

DEPOSIT COMPOSITION - As Required per AWS A5.5-96

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| %C | %Mn | %Si | %Ni | %Cr | %Mo | %V | %S | %P |

|

|

| Requirements | .20 | 1.20 | .60 | 1.00 | 0.30 | .50 | 0.10 | 0.03 | 0.03 |

|

|

| AWS | max. | max. | max. | max. | max. | max. | max. | max. | max. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Typical Results | .15 | .60 | .15 | .67 | .01 | .15 | < .01 | .005 | .008 |

|

NOTE: This AWS electrode classification is not required to deposit weld metal that is low in diffusible hydrogen. Therefore, these electrodes should not be used in applications where the hydrogen content of the weld metal is required to be controlled.

Pipeliner

9 | www.lincolnelectric.com |