PIPELINER

For consistently high impact values, choose 207XP. Optimum perfor- mance on vertical down, hot, fill and cap passes on standard

ADVANTAGE LINCOLN

•Consistently high CVN properties, even down to -40˚F (-40˚C).

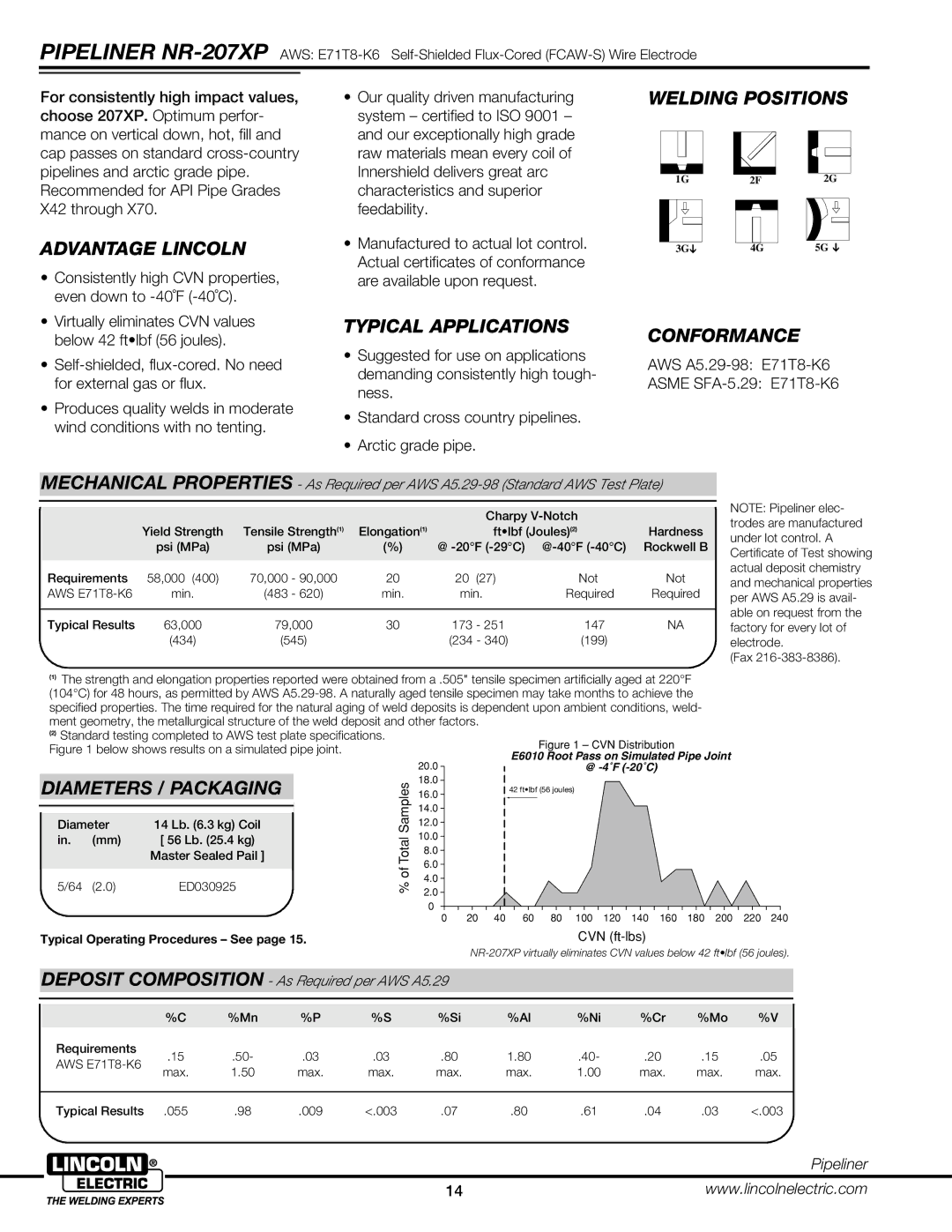

•Virtually eliminates CVN values below 42 ft•lbf (56 joules).

•

•Produces quality welds in moderate wind conditions with no tenting.

•Our quality driven manufacturing system – certified to ISO 9001 – and our exceptionally high grade raw materials mean every coil of Innershield delivers great arc characteristics and superior feedability.

•Manufactured to actual lot control. Actual certificates of conformance are available upon request.

TYPICAL APPLICATIONS

•Suggested for use on applications demanding consistently high tough- ness.

•Standard cross country pipelines.

•Arctic grade pipe.

WELDING POSITIONS

1G | 2F | 2G |

3G➔ | 4G | 5G ➔ |

CONFORMANCE

AWS A5.29-98: E71T8-K6

ASME

MECHANICAL PROPERTIES - As Required per AWS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Charpy |

| |

| Yield Strength | Tensile Strength(1) | Elongation(1) | ft•lbf (Joules)(2) | Hardness | ||

| psi (MPa) | psi (MPa) | (%) | @ | Rockwell B | ||

|

|

|

|

|

|

|

|

Requirements | 58,000 (400) | 70,000 | - 90,000 | 20 | 20 (27) | Not . | Not |

AWS | min. | (483 | - 620) | min. | min. | Required . | Required |

|

|

|

|

|

|

| |

Typical Results | 63,000 | 79,000 | 30 | 173 - 251 | 147 . | NA | |

| (434) | (545) |

| (234 - 340) | (199) .. |

| |

NOTE: Pipeliner elec- trodes are manufactured under lot control. A Certificate of Test showing actual deposit chemistry and mechanical properties per AWS A5.29 is avail- able on request from the factory for every lot of electrode.

(Fax

(1)The strength and elongation properties reported were obtained from a .505" tensile specimen artificially aged at 220°F (104°C) for 48 hours, as permitted by AWS

(2)Standard testing completed to AWS test plate specifications.

Figure 1 below shows results on a simulated pipe joint.

DIAMETERS / PACKAGING

|

|

|

|

|

|

Diameter | 14 Lb. (6.3 kg) Coil | |

in. | (mm) | [ 56 Lb. (25.4 kg) |

|

| Master Sealed Pail ] |

|

|

|

5/64 | (2.0) | ED030925 |

% of Total Samples

20.0

18.0

16.0

14.0

12.0

10.0

8.0

6.0

4.0

2.0

0

0

Typical Operating Procedures – See page 15.

DEPOSIT COMPOSITION - As Required per AWS A5.29

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| %C | %Mn | %P | %S | %Si | %Al | %Ni | %Cr | %Mo | %V |

|

| Requirements | .15 | .50- | .03 | .03 | .80 | 1.80 | .40- | .20 | .15 | .05 |

|

| AWS |

| ||||||||||

| max. | 1.50 | max. | max. | max. | max. | 1.00 | max. | max. | max. |

| |

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

| |

| Typical Results .055 | .98 | .009 | <.003 | .07 | .80 | .61 | .04 | .03 | <.003 |

| |

Pipeliner

14 | www.lincolnelectric.com |