PIPELINER G70M AWS

Pipeliner G70M is designed to deliver outstanding weld properties for

ADVANTAGE LINCOLN

•Impacts are typically in the 60 ft•lbf @

•Smooth, spray type arc transfer and low spatter level.

•Slag system provides for puddle support, good wetting and bead shape in all positions.

•Manufactured under a quality system certified to ISO 9001 requirements.

•Manufactured to actual lot control. Actual certificates of conformance are available upon request.

TYPICAL APPLICATIONS

•All position single and multiple pass wire designed to join pipe up to X70.

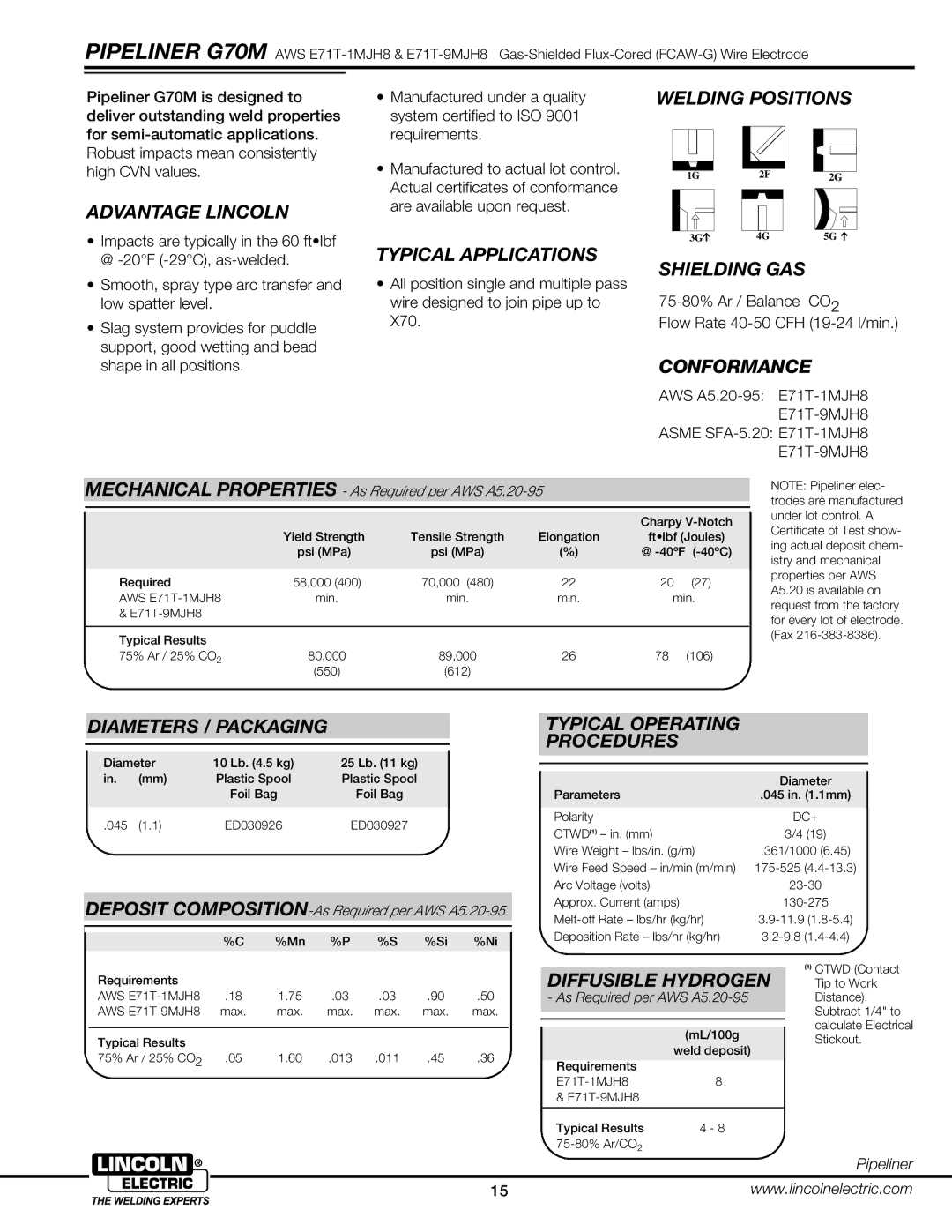

WELDING POSITIONS

1G | 2F | 2G | |

➔ | 4G | 5G | ➔ |

3G |

|

| |

SHIELDING GAS

75-80% Ar / Balance CO2

Flow Rate 40-50 CFH (19-24 l/min.)

CONFORMANCE

AWS

MECHANICAL PROPERTIES - As Required per AWS A5.20-95

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Charpy |

| |

|

| Yield Strength | Tensile Strength | Elongation | ft•lbf (Joules) |

| ||

|

| psi (MPa) | psi (MPa) | (%) | @ |

| ||

|

|

|

|

|

|

|

|

|

| Required | 58,000 (400) | 70,000 | (480) | 22 | 20 | (27) |

|

| AWS | min. | min. | min. | min. |

| ||

| & |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Typical Results |

|

|

|

|

|

|

|

| 75% Ar / 25% CO2 | 80,000 | 89,000 | 26 | 78 | (106) |

| |

|

| (550) | (612) |

|

|

|

| |

NOTE: Pipeliner elec- trodes are manufactured under lot control. A Certificate of Test show- ing actual deposit chem- istry and mechanical properties per AWS A5.20 is available on request from the factory for every lot of electrode. (Fax

DIAMETERS / PACKAGING

|

|

|

|

|

|

|

|

|

|

|

|

| Diameter | 10 Lb. (4.5 kg) | 25 Lb. (11 kg) |

| |

| in. | (mm) | Plastic Spool | Plastic Spool |

|

|

|

| Foil Bag | Foil Bag |

|

|

|

|

|

|

|

| .045 | (1.1) | ED030926 | ED030927 |

|

DEPOSIT COMPOSITION-As Required per AWS A5.20-95

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| %C | %Mn | %P | %S | %Si | %Ni | |

| Requirements |

|

|

|

|

|

|

|

| AWS | .18 | 1.75 | .03 | .03 | .90 | .50 |

|

| AWS | max. | max. | max. | max. | max. | max. | |

|

|

|

|

|

|

|

|

|

| Typical Results |

|

|

|

|

|

|

|

| 75% Ar / 25% CO2 | .05 | 1.60 | .013 | .011 | .45 | .36 |

|

TYPICAL OPERATING

PROCEDURES

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Diameter |

| |||

| Parameters |

| .045 in. (1.1mm) |

| |||

|

|

|

|

|

|

| |

| Polarity |

|

|

| DC+ | ||

| CTWD(1) – in. (mm) |

| 3/4 (19) |

| |||

| Wire Weight – lbs/in. (g/m) |

| .361/1000 (6.45) |

| |||

| Wire Feed Speed – in/min (m/min) |

| |||||

| Arc Voltage (volts) |

|

| ||||

| Approx. Current (amps) |

|

| ||||

|

|

| |||||

| Deposition Rate – lbs/hr (kg/hr) |

| |||||

|

|

|

| (1) | CTWD (Contact | ||

| DIFFUSIBLE HYDROGEN | ||||||

|

| Tip to Work | |||||

| - As Required per AWS |

|

|

| Distance). | ||

|

|

|

|

|

| Subtract 1/4" to | |

|

|

|

|

|

| ||

|

|

|

|

|

| calculate Electrical | |

| (mL/100g |

|

|

| |||

|

|

|

| Stickout. | |||

| weld deposit) |

|

|

| |||

|

|

|

|

|

| ||

| Requirements |

|

|

|

|

|

|

| 8 |

|

|

|

|

| |

| & |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Typical Results | 4 - 8 |

|

Pipeliner

15 | www.lincolnelectric.com |