Pipe Grades

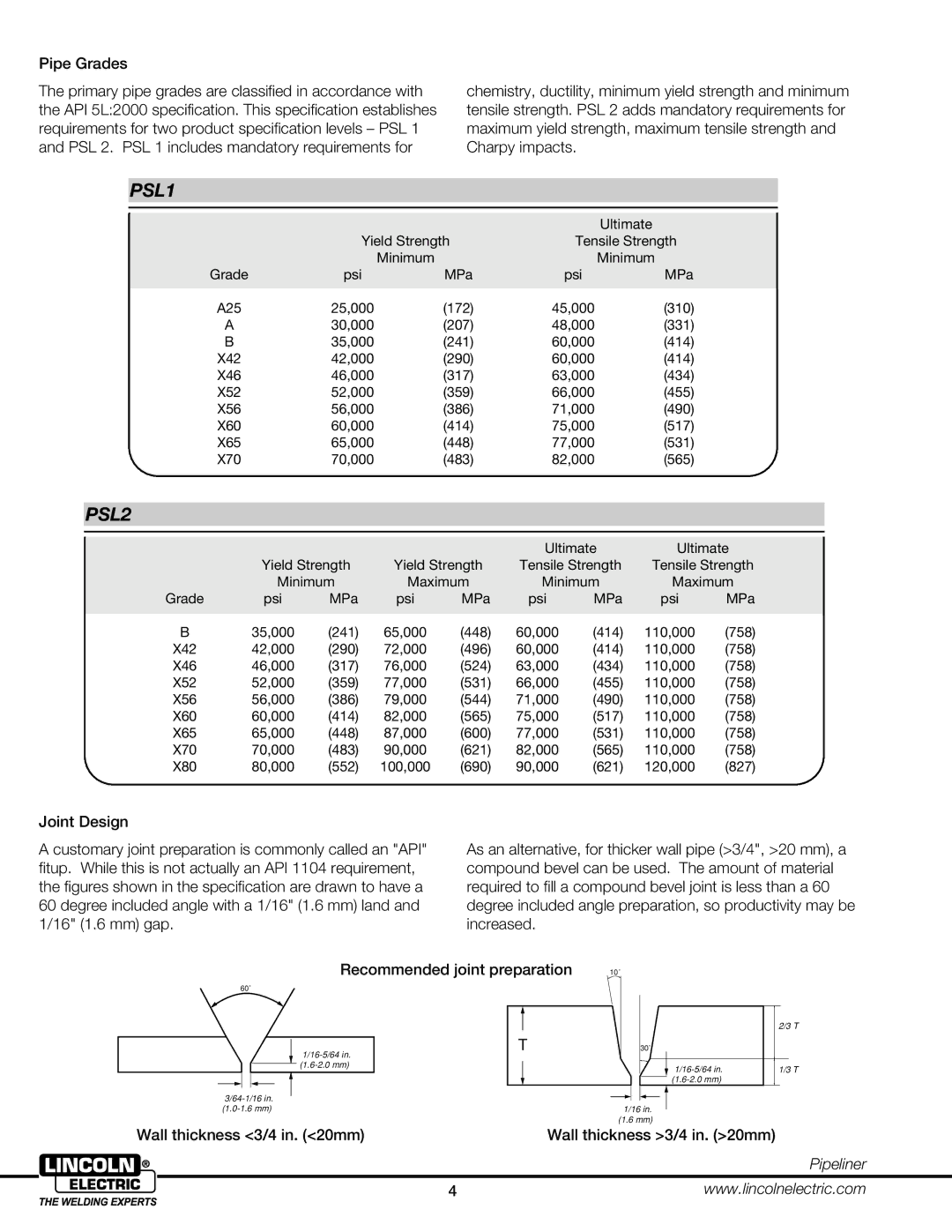

The primary pipe grades are classified in accordance with the API 5L:2000 specification. This specification establishes requirements for two product specification levels – PSL 1 and PSL 2. PSL 1 includes mandatory requirements for

chemistry, ductility, minimum yield strength and minimum tensile strength. PSL 2 adds mandatory requirements for maximum yield strength, maximum tensile strength and Charpy impacts.

PSL1

|

|

|

|

|

|

|

|

|

|

|

|

|

| Ultimate |

| Yield Strength | Tensile Strength | ||

|

| Minimum |

| Minimum |

Grade | psi | MPa | psi | MPa |

|

|

|

|

|

A25 | 25,000 | (172) | 45,000 | (310) |

A | 30,000 | (207) | 48,000 | (331) |

B | 35,000 | (241) | 60,000 | (414) |

X42 | 42,000 | (290) | 60,000 | (414) |

X46 | 46,000 | (317) | 63,000 | (434) |

X52 | 52,000 | (359) | 66,000 | (455) |

X56 | 56,000 | (386) | 71,000 | (490) |

X60 | 60,000 | (414) | 75,000 | (517) |

X65 | 65,000 | (448) | 77,000 | (531) |

X70 | 70,000 | (483) | 82,000 | (565) |

PSL2

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Ultimate | Ultimate | ||

| Yield Strength | Yield Strength | Tensile Strength | Tensile Strength | ||||

| Minimum | Maximum | Minimum | Maximum | ||||

Grade | psi | MPa | psi | MPa | psi | MPa | psi | MPa |

|

|

|

|

|

|

|

|

|

B | 35,000 | (241) | 65,000 | (448) | 60,000 | (414) | 110,000 | (758) |

X42 | 42,000 | (290) | 72,000 | (496) | 60,000 | (414) | 110,000 | (758) |

X46 | 46,000 | (317) | 76,000 | (524) | 63,000 | (434) | 110,000 | (758) |

X52 | 52,000 | (359) | 77,000 | (531) | 66,000 | (455) | 110,000 | (758) |

X56 | 56,000 | (386) | 79,000 | (544) | 71,000 | (490) | 110,000 | (758) |

X60 | 60,000 | (414) | 82,000 | (565) | 75,000 | (517) | 110,000 | (758) |

X65 | 65,000 | (448) | 87,000 | (600) | 77,000 | (531) | 110,000 | (758) |

X70 | 70,000 | (483) | 90,000 | (621) | 82,000 | (565) | 110,000 | (758) |

X80 | 80,000 | (552) | 100,000 | (690) | 90,000 | (621) | 120,000 | (827) |

Joint Design

A customary joint preparation is commonly called an "API" fitup. While this is not actually an API 1104 requirement, the figures shown in the specification are drawn to have a 60 degree included angle with a 1/16" (1.6 mm) land and 1/16" (1.6 mm) gap.

As an alternative, for thicker wall pipe (>3/4", >20 mm), a compound bevel can be used. The amount of material required to fill a compound bevel joint is less than a 60 degree included angle preparation, so productivity may be increased.

Recommended joint preparation | 10˚ |

60˚

Wall thickness <3/4 in. (<20mm)

|

| 2/3 T |

T | 30˚ |

|

| 1/3 T | |

|

|

1/16 in. (1.6 mm)

Wall thickness >3/4 in. (>20mm)

Pipeliner

4 | www.lincolnelectric.com |