PIPELINER 16P AWS: E7016 H4 Low Hydrogen Stick (SMAW) Electrode

We designed this quality electrode for optimum performance for verti- cal up welding of pipe up to API 5L- X65 – especially where a low hydro- gen deposit is desired. Obtain Charpy

•Manufactured under a quality system certified to ISO 9001 requirements.

•Manufactured to actual lot control. Actual certificates of conformance are available upon request.

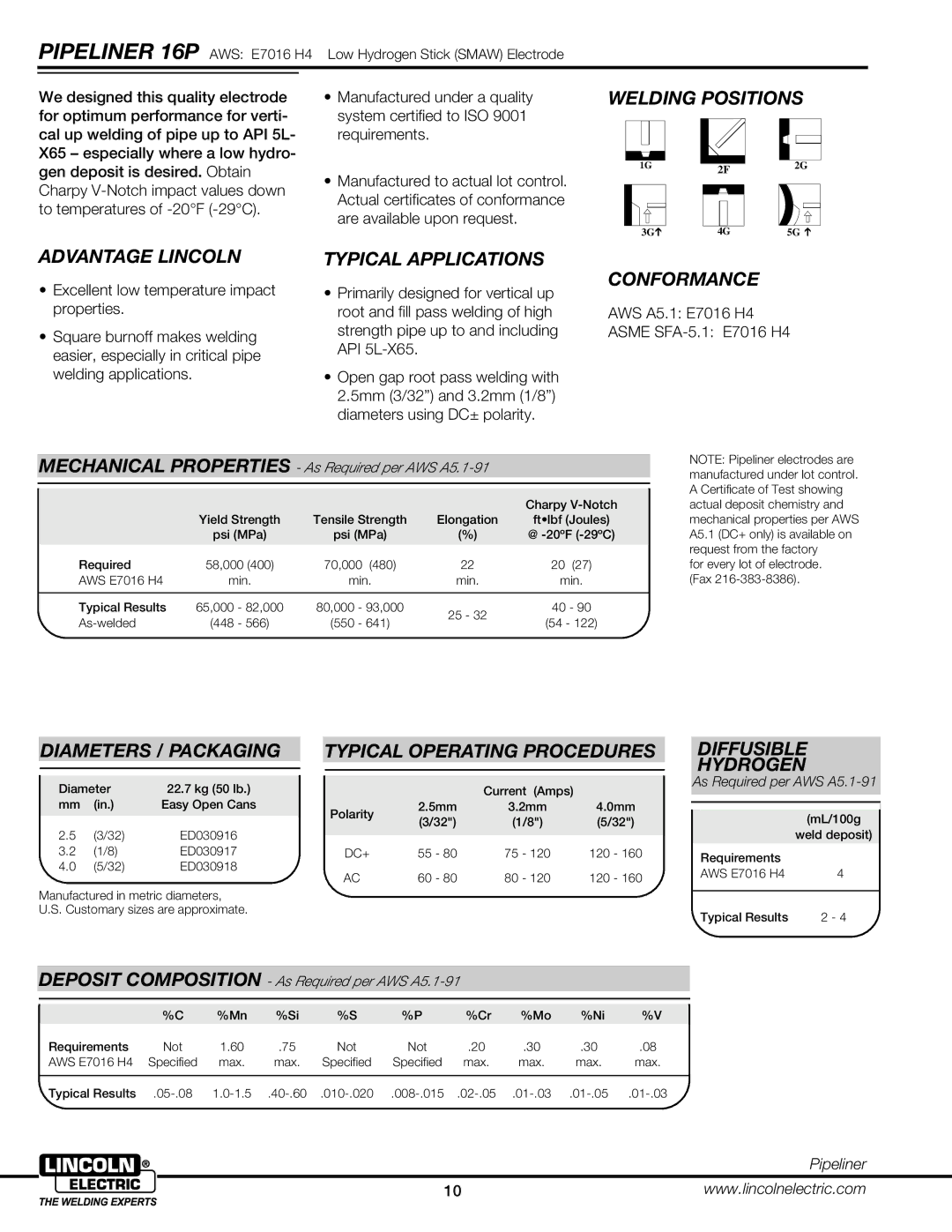

WELDING POSITIONS

1G | 2F | 2G |

3G➔ | 4G | 5G ➔ |

ADVANTAGE LINCOLN

•Excellent low temperature impact properties.

•Square burnoff makes welding easier, especially in critical pipe welding applications.

TYPICAL APPLICATIONS

•Primarily designed for vertical up root and fill pass welding of high strength pipe up to and including API

•Open gap root pass welding with 2.5mm (3/32”) and 3.2mm (1/8”) diameters using DC± polarity.

CONFORMANCE

AWS A5.1: E7016 H4

ASME SFA-5.1: E7016 H4

MECHANICAL PROPERTIES - As Required per AWS A5.1-91

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Charpy | |

|

|

| Yield Strength | Tensile Strength | Elongation | ft•lbf (Joules) | ||||

|

|

| psi (MPa) | psi (MPa) | (%) | @ | ||||

|

| Required | 58,000 (400) | 70,000 | (480) | 22 | 20 | (27) | ||

|

| AWS E7016 H4 | min. | min. | min. | min. | ||||

|

|

|

|

|

|

|

|

|

| |

|

| Typical Results | 65,000 | - 82,000 | 80,000 | - | 93,000 | 25 - 32 | 40 - 90 | |

|

| (448 | - 566) | (550 | - | 641) | (54 - 122) | |||

|

|

| ||||||||

NOTE: Pipeliner electrodes are manufactured under lot control. A Certificate of Test showing actual deposit chemistry and mechanical properties per AWS A5.1 (DC+ only) is available on request from the factory

for every lot of electrode. (Fax

|

| DIAMETERS / PACKAGING |

|

| TYPICAL OPERATING PROCEDURES |

|

| DIFFUSIBLE | |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| HYDROGEN | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

| Diameter | 22.7 kg (50 lb.) |

|

|

|

|

| Current (Amps) |

|

| As Required per AWS | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

| mm | (in.) | Easy Open Cans |

|

|

| Polarity | 2.5mm |

| 3.2mm | 4.0mm |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

| (3/32") |

| (1/8") | (5/32") |

|

|

|

| (mL/100g | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

2.5 | (3/32) | ED030916 |

|

|

|

|

|

|

|

|

|

|

|

|

| weld deposit) | |||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

3.2 | (1/8) | ED030917 |

|

|

| DC+ | 55 - 80 |

| 75 - 120 | 120 - 160 |

|

|

| Requirements |

| ||||

4.0 | (5/32) | ED030918 |

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

| AC | 60 - 80 |

| 80 - 120 | 120 - 160 |

|

|

| AWS E7016 H4 | 4 | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

| Manufactured in metric diameters, |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

| U.S. Customary sizes are approximate. |

|

|

|

|

|

|

|

|

|

|

|

| Typical Results | 2 - 4 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

| DEPOSIT COMPOSITION - As Required per AWS |

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| %C | %Mn | %Si |

| %S | %P | %Cr | %Mo | %Ni | %V |

|

|

|

| ||

|

| Requirements | Not | 1.60 | .75 |

|

| Not | Not | .20 | .30 | .30 | .08 |

|

|

|

|

| |

|

| AWS E7016 H4 | Specified | max. | max. | Specified | Specified | max. | max. | max. | max. |

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

| Typical Results |

|

|

|

| |||||||||||||

Pipeliner

10 | www.lincolnelectric.com |