PIPELINER 6P+ AWS: E6010 Cellulosic

Pipeliner 6P+ is an

•Manufactured under a quality system certified to ISO 9001 requirements.

•Manufactured to actual lot control. Actual certificates of conformance are available upon request.

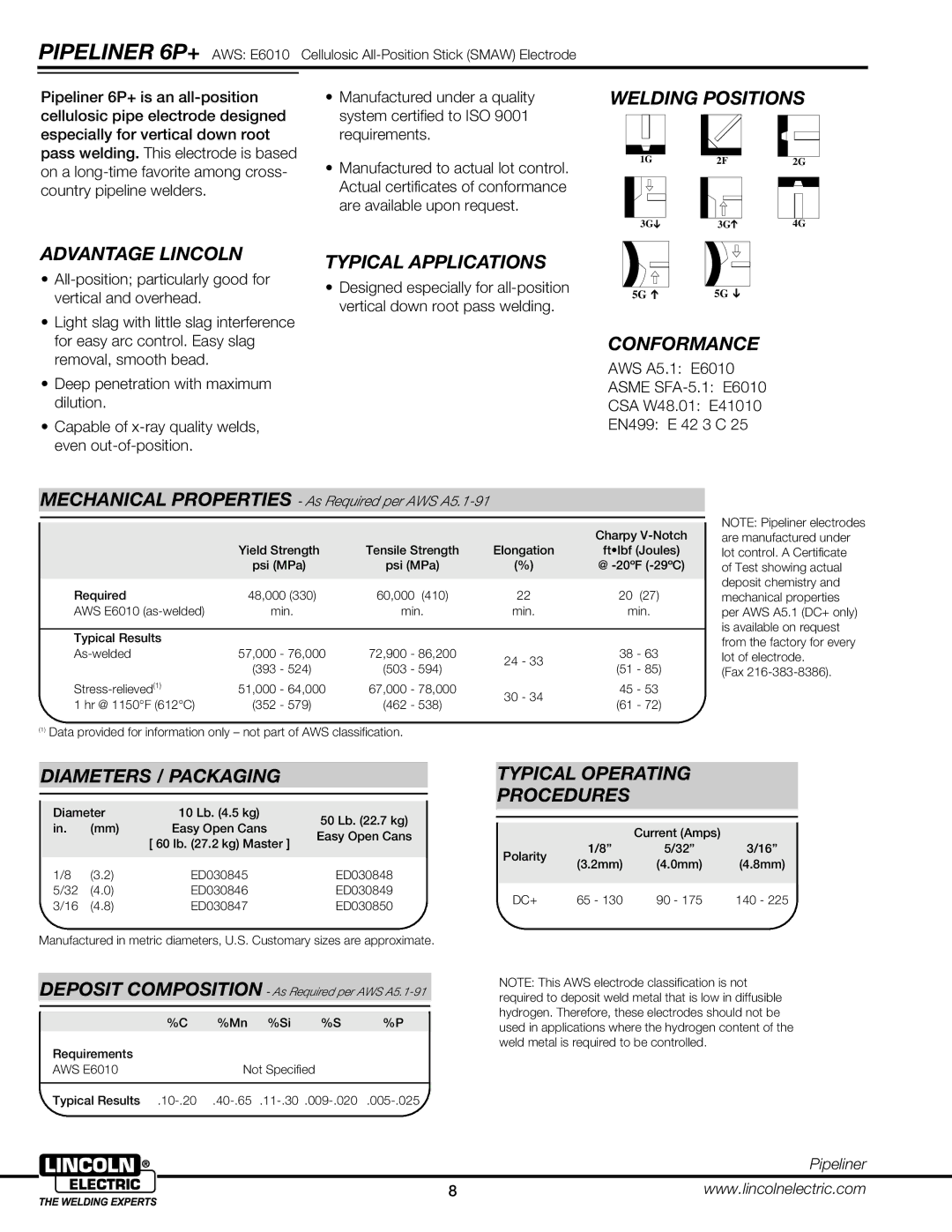

WELDING POSITIONS

1G | 2F | 2G |

3G➔ | 3G➔ | 4G |

ADVANTAGE LINCOLN

•

•Light slag with little slag interference for easy arc control. Easy slag removal, smooth bead.

•Deep penetration with maximum dilution.

•Capable of

TYPICAL APPLICATIONS

•Designed especially for

5G | ➔ | 5G | ➔ |

CONFORMANCE

AWS A5.1: E6010

ASME

CSA W48.01: E41010

EN499: E 42 3 C 25

MECHANICAL PROPERTIES - As Required per AWS A5.1-91

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Charpy |

| |

|

| Yield Strength | Tensile Strength | Elongation | ft•lbf (Joules) |

| |||||

|

| psi (MPa) | psi (MPa) | (%) | @ |

| |||||

|

|

|

|

|

|

|

|

| |||

| Required | 48,000 (330) | 60,000 | (410) | 22 | 20 | (27) |

| |||

| AWS E6010 | min. | min. | min. | min. |

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

| Typical Results |

|

|

|

|

|

|

|

|

|

|

| 57,000 | - | 76,000 | 72,900 | - | 86,200 | 24 - 33 | 38 | - 63 |

| |

|

| (393 | - | 524) | (503 | - | 594) | (51 | - 85) |

| |

|

|

|

| ||||||||

| 51,000 | - | 64,000 | 67,000 | - | 78,000 | 30 - 34 | 45 | - 53 |

| |

| 1 hr @ 1150°F (612°C) | (352 | - | 579) | (462 | - | 538) | (61 | - 72) |

| |

|

|

| |||||||||

(1)Data provided for information only – not part of AWS classification.

NOTE: Pipeliner electrodes are manufactured under lot control. A Certificate of Test showing actual deposit chemistry and mechanical properties per AWS A5.1 (DC+ only) is available on request from the factory for every lot of electrode.

(Fax

DIAMETERS / PACKAGING

TYPICAL OPERATING PROCEDURES

Diameter | 10 Lb. (4.5 kg) | 50 Lb. (22.7 kg) | ||

in. | (mm) | Easy Open Cans | ||

Easy Open Cans | ||||

|

| [ 60 lb. (27.2 kg) Master ] | ||

|

|

| ||

Polarity

Current (Amps)

1/8” 5/32” 3/16”

1/8 | (3.2) | ED030845 | ED030848 |

5/32 | (4.0) | ED030846 | ED030849 |

3/16 | (4.8) | ED030847 | ED030850 |

Manufactured in metric diameters, U.S. Customary sizes are approximate.

DEPOSIT COMPOSITION - As Required per AWS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| %C | %Mn | %Si | %S | %P |

|

|

| Requirements |

|

|

|

|

|

|

| AWS E6010 | Not Specified |

|

|

|

| |

|

|

|

|

|

|

| |

| Typical |

|

| ||||

(3.2mm) (4.0mm) (4.8mm)

DC+ 65 - 130 90 - 175 140 - 225

NOTE: This AWS electrode classification is not required to deposit weld metal that is low in diffusible hydrogen. Therefore, these electrodes should not be used in applications where the hydrogen content of the weld metal is required to be controlled.

Pipeliner

8 | www.lincolnelectric.com |