OPERATION | ||

|

|

|

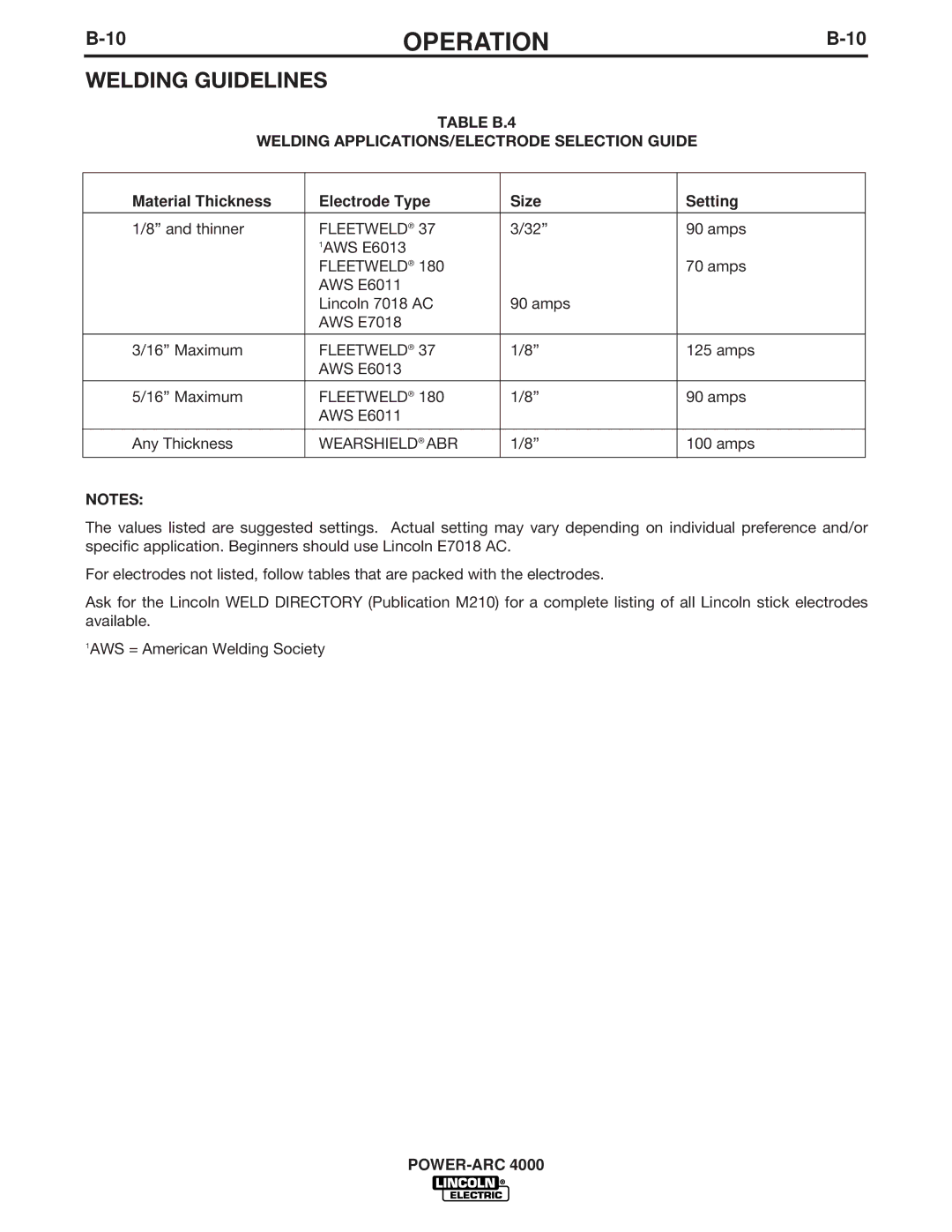

WELDING GUIDELINES

TABLE B.4

WELDING APPLICATIONS/ELECTRODE SELECTION GUIDE

Material Thickness | Electrode Type | Size | Setting |

|

|

|

|

1/8” and thinner | FLEETWELD® 37 | 3/32” | 90 amps |

| 1AWS E6013 |

|

|

| FLEETWELD® 180 |

| 70 amps |

| AWS E6011 |

|

|

| Lincoln 7018 AC | 90 amps |

|

| AWS E7018 |

|

|

|

|

|

|

3/16” Maximum | FLEETWELD® 37 | 1/8” | 125 amps |

| AWS E6013 |

|

|

|

|

|

|

5/16” Maximum | FLEETWELD® 180 | 1/8” | 90 amps |

| AWS E6011 |

|

|

|

|

|

|

Any Thickness | WEARSHIELD® ABR | 1/8” | 100 amps |

|

|

|

|

NOTES:

The values listed are suggested settings. Actual setting may vary depending on individual preference and/or specific application. Beginners should use Lincoln E7018 AC.

For electrodes not listed, follow tables that are packed with the electrodes.

Ask for the Lincoln WELD DIRECTORY (Publication M210) for a complete listing of all Lincoln stick electrodes available.

1AWS = American Welding Society