OPERATION | ||

|

|

|

The

![]() WARNING

WARNING

ELECTRIC SHOCK can kill.

• Do not touch electrically live parts or electrode with skin or wet cloth- ing.

•Insulate yourself from work and ground.

•Always wear dry insulating gloves.

cannot be looked at with the naked eye without risking painful and possibly permanent injury. A very dark lens, specifically designed for arc welding must be used with the handshield or headshield whenever viewing the arc.

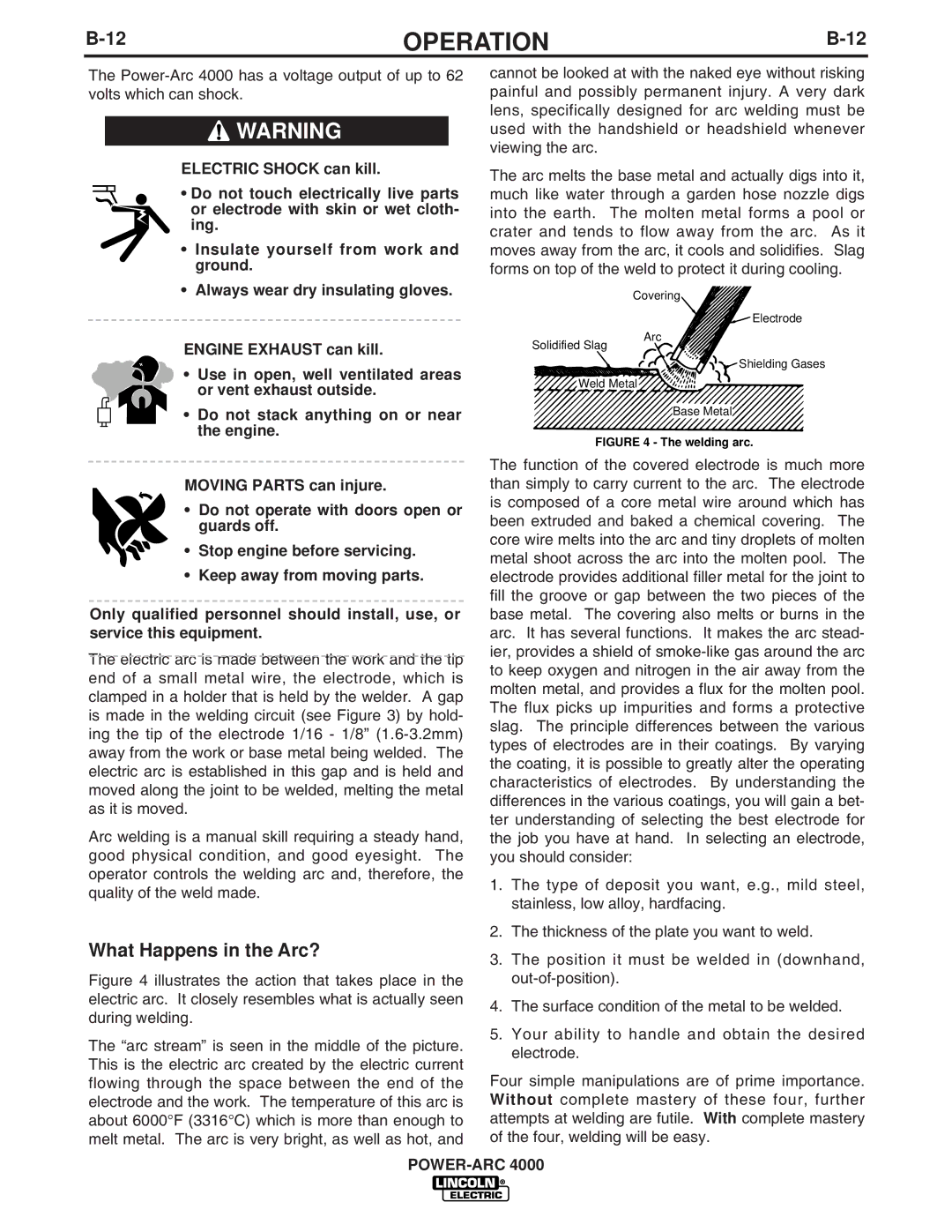

The arc melts the base metal and actually digs into it, much like water through a garden hose nozzle digs into the earth. The molten metal forms a pool or crater and tends to flow away from the arc. As it moves away from the arc, it cools and solidifies. Slag forms on top of the weld to protect it during cooling.

Covering

ENGINE EXHAUST can kill.

Solidified Slag

Electrode

Arc

Shielding Gases

• Use in open, well ventilated areas or vent exhaust outside.

• Do not stack anything on or near the engine.

MOVING PARTS can injure.

•Do not operate with doors open or guards off.

• Stop engine before servicing.

•Keep away from moving parts.

Only qualified personnel should install, use, or service this equipment.

The electric arc is made between the work and the tip end of a small metal wire, the electrode, which is clamped in a holder that is held by the welder. A gap is made in the welding circuit (see Figure 3) by hold- ing the tip of the electrode 1/16 - 1/8”

Arc welding is a manual skill requiring a steady hand, good physical condition, and good eyesight. The operator controls the welding arc and, therefore, the quality of the weld made.

![]() Weld Metal

Weld Metal ![]()

![]()

![]()

![]()

![]()

Base Metal

FIGURE 4 - The welding arc.

The function of the covered electrode is much more than simply to carry current to the arc. The electrode is composed of a core metal wire around which has been extruded and baked a chemical covering. The core wire melts into the arc and tiny droplets of molten metal shoot across the arc into the molten pool. The electrode provides additional filler metal for the joint to fill the groove or gap between the two pieces of the base metal. The covering also melts or burns in the arc. It has several functions. It makes the arc stead- ier, provides a shield of

1.The type of deposit you want, e.g., mild steel, stainless, low alloy, hardfacing.

2.The thickness of the plate you want to weld.