Work Cable Installation

1.Open the wire feed section door on the right side of the

2.Pass the end of the work cable that has the termi- nal lug with the smaller hole through the hole (hole D) next to the louvers in the case front.

3.Route the cable under and around the back of the wire feed unit.

4.Using wing nut provided, connect the terminal lug to the negative

NOTE: This connection gives the correct electrode polarity for the GMAW process. If using Innershield, see Output Polarity Connection Section below for negative electrode polarity connection.

OUTPUT POLARITY CONNECTION

The

To connect for negative electrode polarity (required for the Innershield process), connect the short cable attached to the gun connector block to the negative

(+)terminal using the provided wing nuts (make cer- tain that both wing nuts are tight).

GUN INSTALLATION

As shipped from the factory, the

mm)wire is to be used, install the .030" (0.8 mm) con- tact tip. .023

If .035" (0.9 mm) Innershield flux cored wire is to be used, see Maintenance Section for instructions to change contact tip, cable liner, and gas nozzle.

Connect the gun cable to the

1.Unplug the machine or turn power switch to the off “O” position.

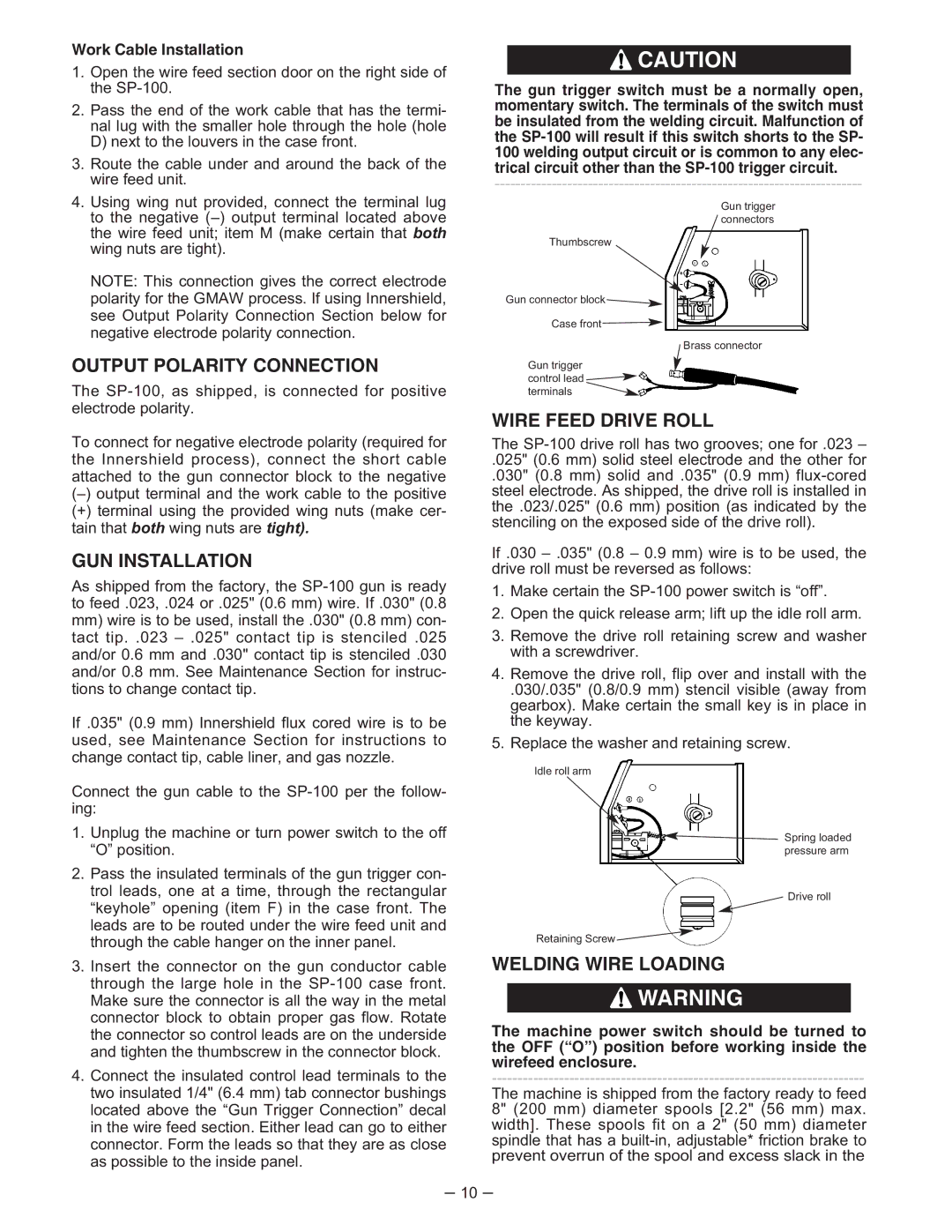

2.Pass the insulated terminals of the gun trigger con- trol leads, one at a time, through the rectangular “keyhole” opening (item F) in the case front. The leads are to be routed under the wire feed unit and through the cable hanger on the inner panel.

3.Insert the connector on the gun conductor cable through the large hole in the

4.Connect the insulated control lead terminals to the two insulated 1/4" (6.4 mm) tab connector bushings located above the “Gun Trigger Connection” decal in the wire feed section. Either lead can go to either connector. Form the leads so that they are as close as possible to the inside panel.

![]() CAUTION

CAUTION

The gun trigger switch must be a normally open, momentary switch. The terminals of the switch must be insulated from the welding circuit. Malfunction of the

Gun trigger connectors

Thumbscrew

Gun connector block | { |

| |

Case front |

|

![]() Brass connector

Brass connector

Gun trigger control lead ![]() terminals

terminals ![]()

WIRE FEED DRIVE ROLL

The

.025" (0.6 mm) solid steel electrode and the other for

.030" (0.8 mm) solid and .035" (0.9 mm)

If .030

1.Make certain the

2.Open the quick release arm; lift up the idle roll arm.

3.Remove the drive roll retaining screw and washer with a screwdriver.

4.Remove the drive roll, flip over and install with the

.030/.035" (0.8/0.9 mm) stencil visible (away from gearbox). Make certain the small key is in place in the keyway.

5.Replace the washer and retaining screw.

Idle roll arm

Spring loaded pressure arm

Drive roll

Retaining Screw![]()

WELDING WIRE LOADING

![]() WARNING

WARNING

The machine power switch should be turned to the OFF (“O”) position before working inside the wirefeed enclosure.

The machine is shipped from the factory ready to feed 8" (200 mm) diameter spools [2.2" (56 mm) max. width]. These spools fit on a 2" (50 mm) diameter spindle that has a

– 10 –