steel can usually be easily welded without special pre- cautions. Some steels, however, contain higher car- bon levels or other alloys and are more difficult to weld. Basically, if a magnet sticks to the metal and if you can easily cut the metal with a file, chances are good that you will be able to weld the material with the

Regardless of the type of metal being welded, it is important in order to get a quality weld that it be free of oil, paint, rust or other contaminant's.

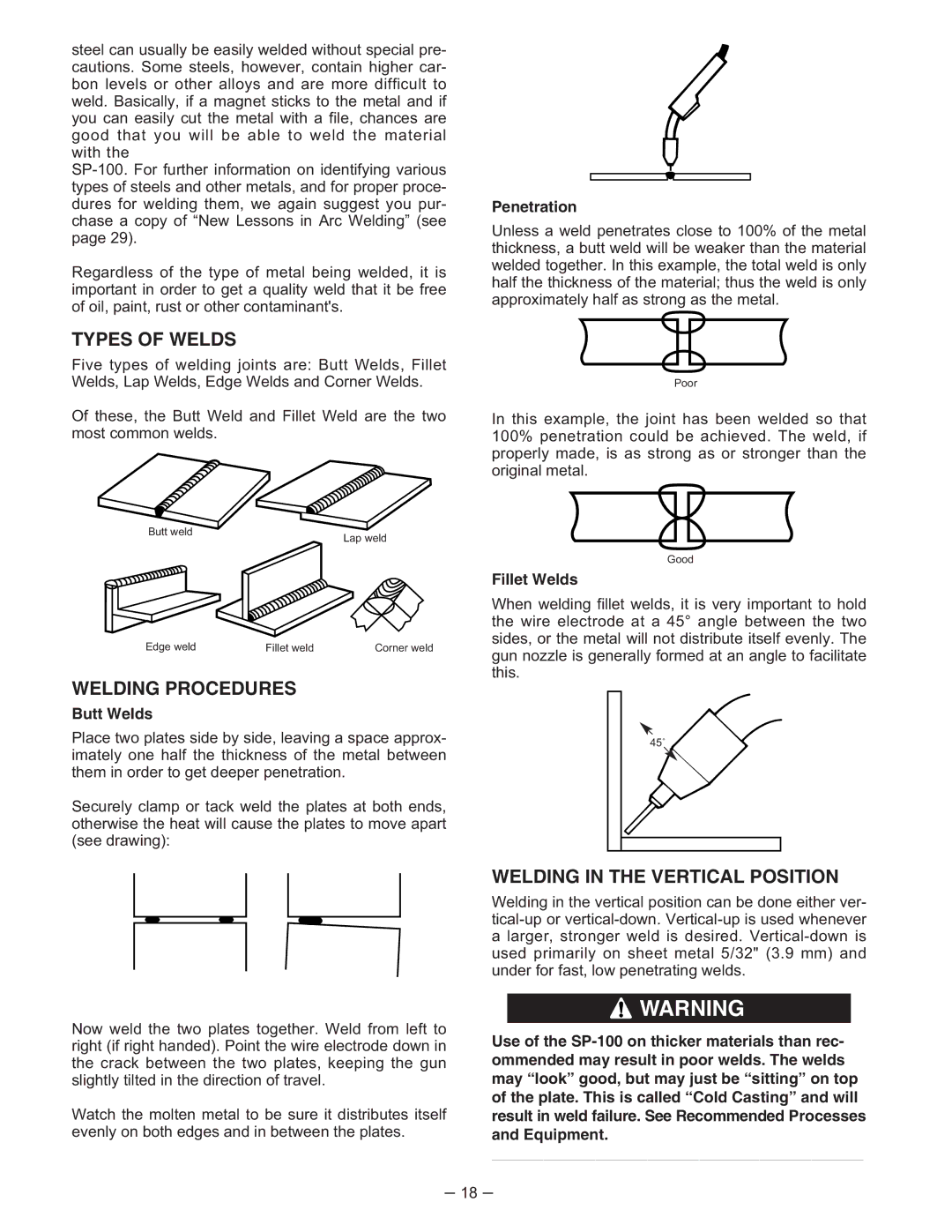

TYPES OF WELDS

Five types of welding joints are: Butt Welds, Fillet Welds, Lap Welds, Edge Welds and Corner Welds.

Of these, the Butt Weld and Fillet Weld are the two most common welds.

Butt weld

Lap weld

Edge weld | Fillet weld | Corner weld |

WELDING PROCEDURES

Butt Welds

Place two plates side by side, leaving a space approx- imately one half the thickness of the metal between them in order to get deeper penetration.

Securely clamp or tack weld the plates at both ends, otherwise the heat will cause the plates to move apart (see drawing):

Now weld the two plates together. Weld from left to right (if right handed). Point the wire electrode down in the crack between the two plates, keeping the gun slightly tilted in the direction of travel.

Watch the molten metal to be sure it distributes itself evenly on both edges and in between the plates.

Penetration

Unless a weld penetrates close to 100% of the metal thickness, a butt weld will be weaker than the material welded together. In this example, the total weld is only half the thickness of the material; thus the weld is only approximately half as strong as the metal.

Poor

In this example, the joint has been welded so that 100% penetration could be achieved. The weld, if properly made, is as strong as or stronger than the original metal.

Good

Fillet Welds

When welding fillet welds, it is very important to hold the wire electrode at a 45° angle between the two sides, or the metal will not distribute itself evenly. The gun nozzle is generally formed at an angle to facilitate this.

45˚

WELDING IN THE VERTICAL POSITION

Welding in the vertical position can be done either ver-

alarger, stronger weld is desired.

![]() WARNING

WARNING

Use of the

___________________________________________

– 18 –