Vertical-Up and Overhead Welding

The problem, when welding

When welding

Generally, keep the electrode nearly perpendicular to the joint as illustrated. The maximum angle above per- pendicular may be required if porosity becomes a problem.

Maximum plate thickness 5/16” (8.0mm)

Vertical-Down Welding

Use stringer beads and tip the gun in the direction of travel so the arc force helps hold the molten metal in the joint. Move as fast as possible consistent with desired bead shape.

The important thing is to continue lowering the entire arm as the weld is made so the angle of the gun does not change. Move the electrode wire fast enough that the slag does not catch up with the arc.

THE GMAW (MIG) WELDING ARC

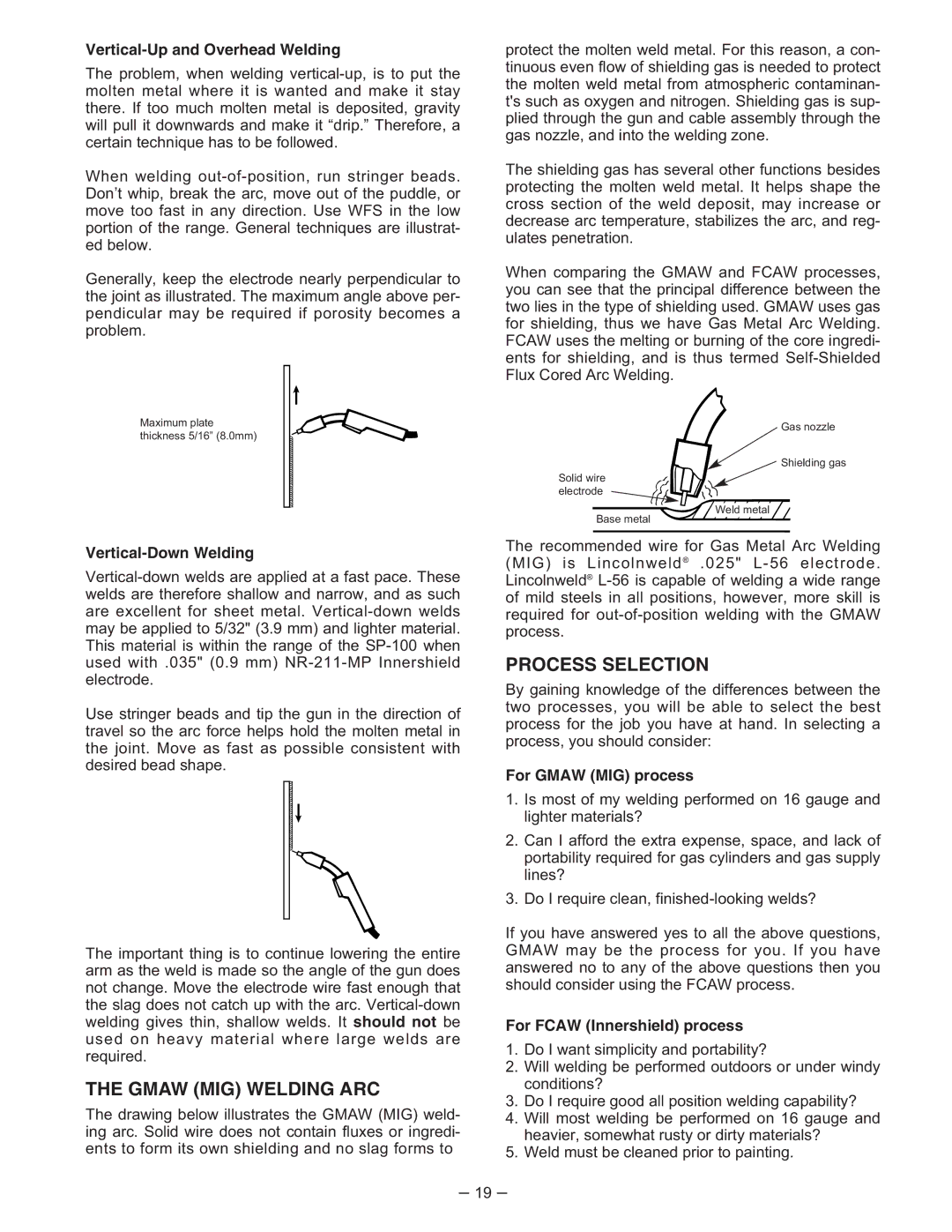

The drawing below illustrates the GMAW (MIG) weld- ing arc. Solid wire does not contain fluxes or ingredi- ents to form its own shielding and no slag forms to

protect the molten weld metal. For this reason, a con- tinuous even flow of shielding gas is needed to protect the molten weld metal from atmospheric contaminan- t's such as oxygen and nitrogen. Shielding gas is sup- plied through the gun and cable assembly through the gas nozzle, and into the welding zone.

The shielding gas has several other functions besides protecting the molten weld metal. It helps shape the cross section of the weld deposit, may increase or decrease arc temperature, stabilizes the arc, and reg- ulates penetration.

When comparing the GMAW and FCAW processes, you can see that the principal difference between the two lies in the type of shielding used. GMAW uses gas for shielding, thus we have Gas Metal Arc Welding. FCAW uses the melting or burning of the core ingredi- ents for shielding, and is thus termed

Gas nozzle

Shielding gas

Solid wire electrode

Weld metal

Base metal

The recommended wire for Gas Metal Arc Welding (MIG) is Lincolnweld® .025"

PROCESS SELECTION

By gaining knowledge of the differences between the two processes, you will be able to select the best process for the job you have at hand. In selecting a process, you should consider:

For GMAW (MIG) process

1.Is most of my welding performed on 16 gauge and lighter materials?

2.Can I afford the extra expense, space, and lack of portability required for gas cylinders and gas supply lines?

3.Do I require clean,

If you have answered yes to all the above questions, GMAW may be the process for you. If you have answered no to any of the above questions then you should consider using the FCAW process.

For FCAW (Innershield) process

1.Do I want simplicity and portability?

2.Will welding be performed outdoors or under windy conditions?

3.Do I require good all position welding capability?

4.Will most welding be performed on 16 gauge and heavier, somewhat rusty or dirty materials?

5.Weld must be cleaned prior to painting.

– 19 –