OPERATION | ||

|

|

|

•WELDING MODE

May be selected by name (CV/MIG, CC/Stick Crisp, Gouge, etc.) or by a mode number (10, 24, 71, etc.) depending on the Control Box options. Selecting a welding mode determines the output characteristics of the Power Wave power source. For a more complete description of the welding modes available in the Power Wave, see the explanation below.

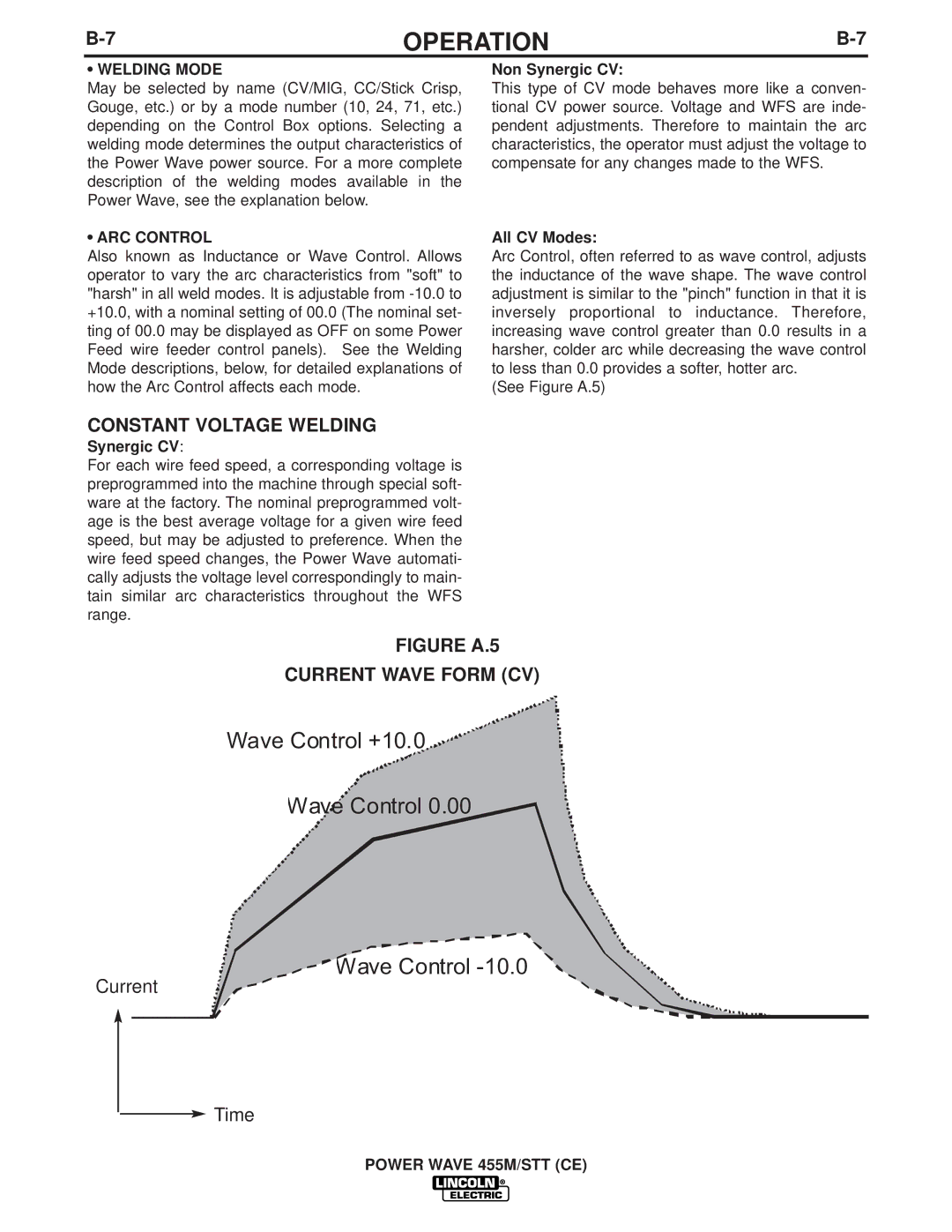

•ARC CONTROL

Also known as Inductance or Wave Control. Allows operator to vary the arc characteristics from "soft" to "harsh" in all weld modes. It is adjustable from

Non Synergic CV:

This type of CV mode behaves more like a conven- tional CV power source. Voltage and WFS are inde- pendent adjustments. Therefore to maintain the arc characteristics, the operator must adjust the voltage to compensate for any changes made to the WFS.

All CV Modes:

Arc Control, often referred to as wave control, adjusts the inductance of the wave shape. The wave control adjustment is similar to the "pinch" function in that it is inversely proportional to inductance. Therefore, increasing wave control greater than 0.0 results in a harsher, colder arc while decreasing the wave control to less than 0.0 provides a softer, hotter arc.

(See Figure A.5)

CONSTANT VOLTAGE WELDING

Synergic CV:

For each wire feed speed, a corresponding voltage is preprogrammed into the machine through special soft- ware at the factory. The nominal preprogrammed volt- age is the best average voltage for a given wire feed speed, but may be adjusted to preference. When the wire feed speed changes, the Power Wave automati- cally adjusts the voltage level correspondingly to main- tain similar arc characteristics throughout the WFS range.

FIGURE A.5

CURRENT WAVE FORM (CV)

Wave Control +10.0 ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Wave Control 0.00

![]()

![]()

![]() Wave Control

Wave Control

Current

Time