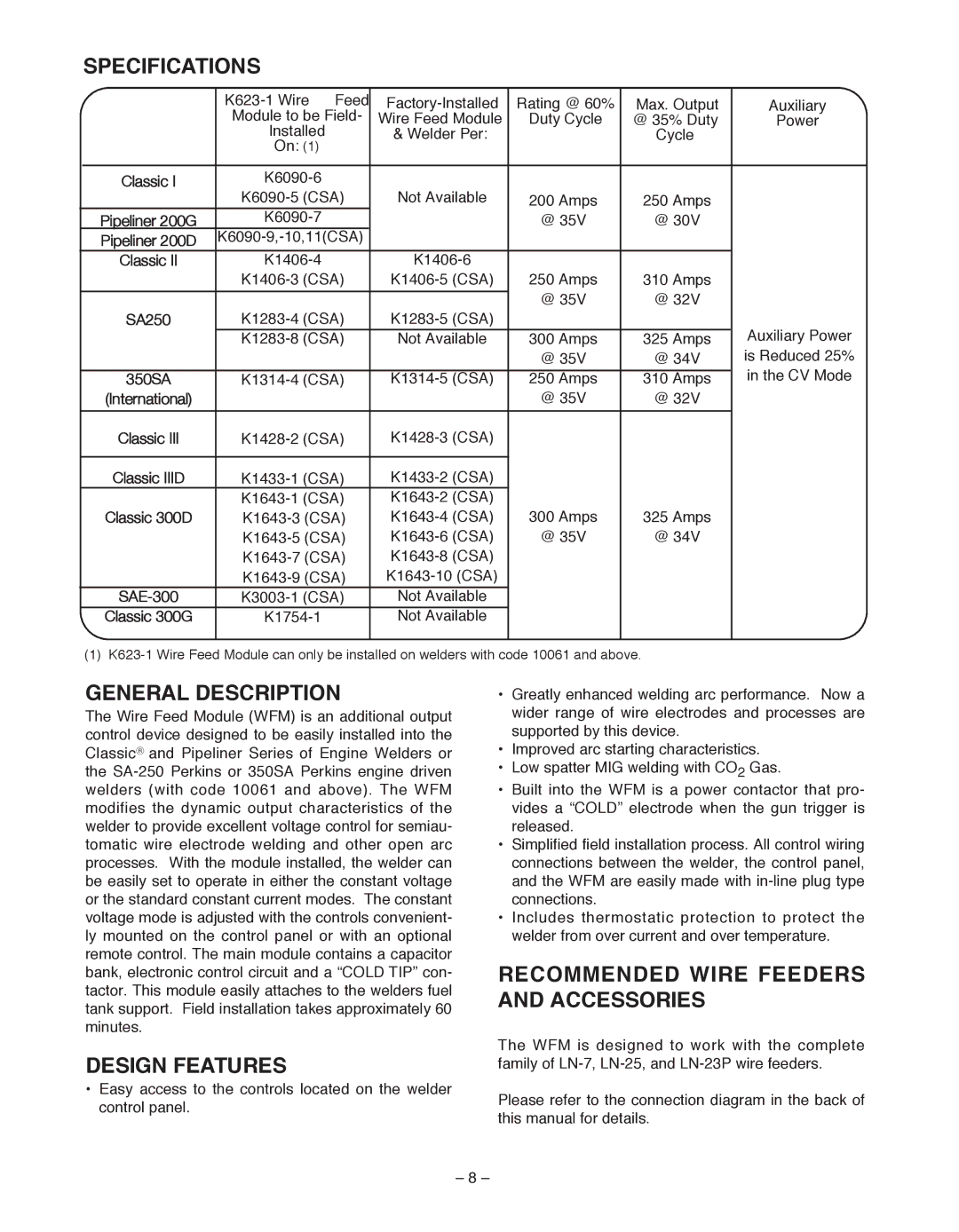

SPECIFICATIONS

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

| Rating @ 60% |

|

| Max. Output |

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| Auxiliary |

|

| |||||||||||

|

|

| Module to be Field- |

| Wire Feed Module |

| Duty Cycle |

|

| @ 35% Duty |

|

|

|

| Power |

|

| ||||

|

|

| Installed |

|

| & Welder Per: |

|

|

|

|

| Cycle |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

| On: (1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Classic I |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| Not Available |

|

|

| 200 Amps |

|

|

| 250 Amps |

|

|

|

|

|

|

| |

| Pipeliner 200G |

|

|

|

|

|

|

| @ 35V |

|

|

| @ 30V |

|

|

|

|

|

|

| |

| Pipeliner 200D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Classic II |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| 250 Amps |

|

|

| 310 Amps |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| @ 35V |

|

|

| @ 32V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| SA250 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| Not Available |

|

|

| 300 Amps |

|

|

| 325 Amps |

|

|

|

| Auxiliary Power |

| ||

|

|

|

|

|

|

|

|

|

| @ 35V |

|

|

| @ 34V |

|

|

| is Reduced 25% |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| in the CV Mode |

| |

| 350SA |

|

|

|

|

|

| 250 Amps |

|

|

| 310 Amps |

|

|

|

|

| ||||

| (International) |

|

|

|

|

|

|

|

| @ 35V |

|

|

| @ 32V |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Classic III |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Classic IIID |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Classic 300D |

|

|

|

|

|

| 300 Amps |

|

|

| 325 Amps |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| @ 35V |

|

|

| @ 34V |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

| Not Available |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| Classic 300G |

|

|

| Not Available |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(1)

GENERAL DESCRIPTION

The Wire Feed Module (WFM) is an additional output control device designed to be easily installed into the Classic® and Pipeliner Series of Engine Welders or the

DESIGN FEATURES

•Easy access to the controls located on the welder control panel.

•Greatly enhanced welding arc performance. Now a wider range of wire electrodes and processes are supported by this device.

•Improved arc starting characteristics.

•Low spatter MIG welding with CO2 Gas.

•Built into the WFM is a power contactor that pro- vides a “COLD” electrode when the gun trigger is released.

•Simplified field installation process. All control wiring connections between the welder, the control panel, and the WFM are easily made with

•Includes thermostatic protection to protect the welder from over current and over temperature.

RECOMMENDED WIRE FEEDERS AND ACCESSORIES

The WFM is designed to work with the complete family of

Please refer to the connection diagram in the back of this manual for details.

– 8 –