OPERATION | ||

|

|

|

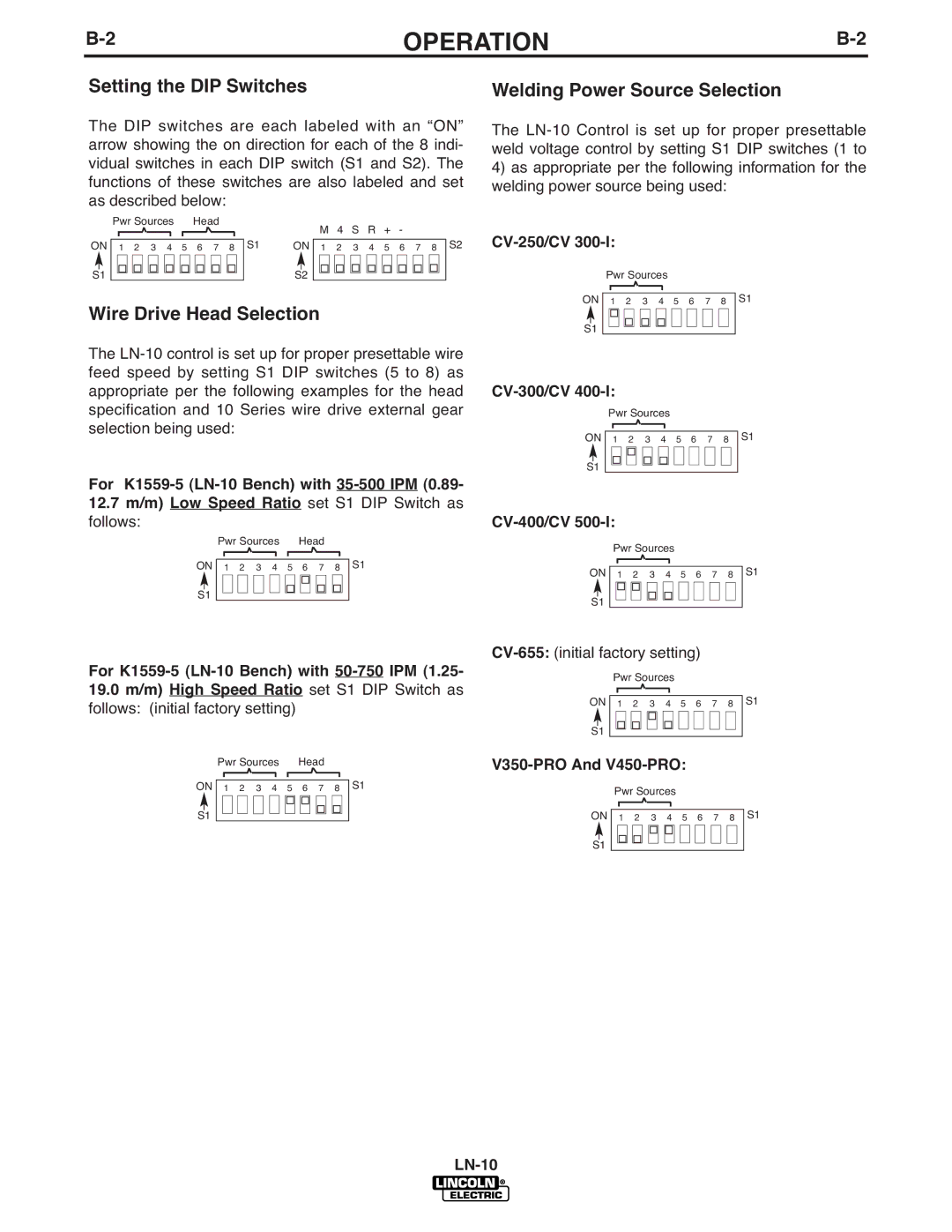

Setting the DIP Switches

The DIP switches are each labeled with an “ON” arrow showing the on direction for each of the 8 indi- vidual switches in each DIP switch (S1 and S2). The functions of these switches are also labeled and set as described below:

| Pwr Sources Head |

|

| M 4 S R | + - |

|

| ||||||||||||||

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

| S1 | ON |

|

| S2 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

1 2 3 4 5 6 7 8 |

|

| 1 2 3 4 | 5 6 7 8 | |||||||||||||||||

S1 | S2 |

Wire Drive Head Selection

The

For

12.7m/m) Low Speed Ratio set S1 DIP Switch as follows:

|

|

| Pwr Sources |

|

| Head |

|

|

|

| |||||||||||||

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| S1 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

| 1 | 2 | 3 | 4 | 5 | 6 |

|

| 7 |

| 8 |

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

For K1559-5 (LN-10 Bench) with 50-750 IPM (1.25-

19.0m/m) High Speed Ratio set S1 DIP Switch as follows: (initial factory setting)

|

|

| Pwr Sources |

|

|

| Head |

|

|

|

|

| ||||||||||||||

ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| S1 | ||

| 1 | 2 | 3 | 4 | 5 | 6 |

|

| 7 |

| 8 |

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Welding Power Source Selection

The

4)as appropriate per the following information for the welding power source being used:

Pwr Sources

ON |

|

|

|

|

|

|

|

|

| S1 |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1

Pwr Sources

ON |

|

|

|

|

|

|

|

| S1 |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1

Pwr Sources

ON |

|

|

|

|

|

|

|

|

|

| S1 |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1

Pwr Sources

ON |

|

|

|

|

|

|

|

| S1 |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1

Pwr Sources

ON |

|

|

|

|

|

|

|

|

| S1 | |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S1