|

|

|

|

|

| INSTALLATION |

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TECHNICAL SPECIFICATIONS – |

|

|

|

| |||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

SPEC.# |

| TYPE |

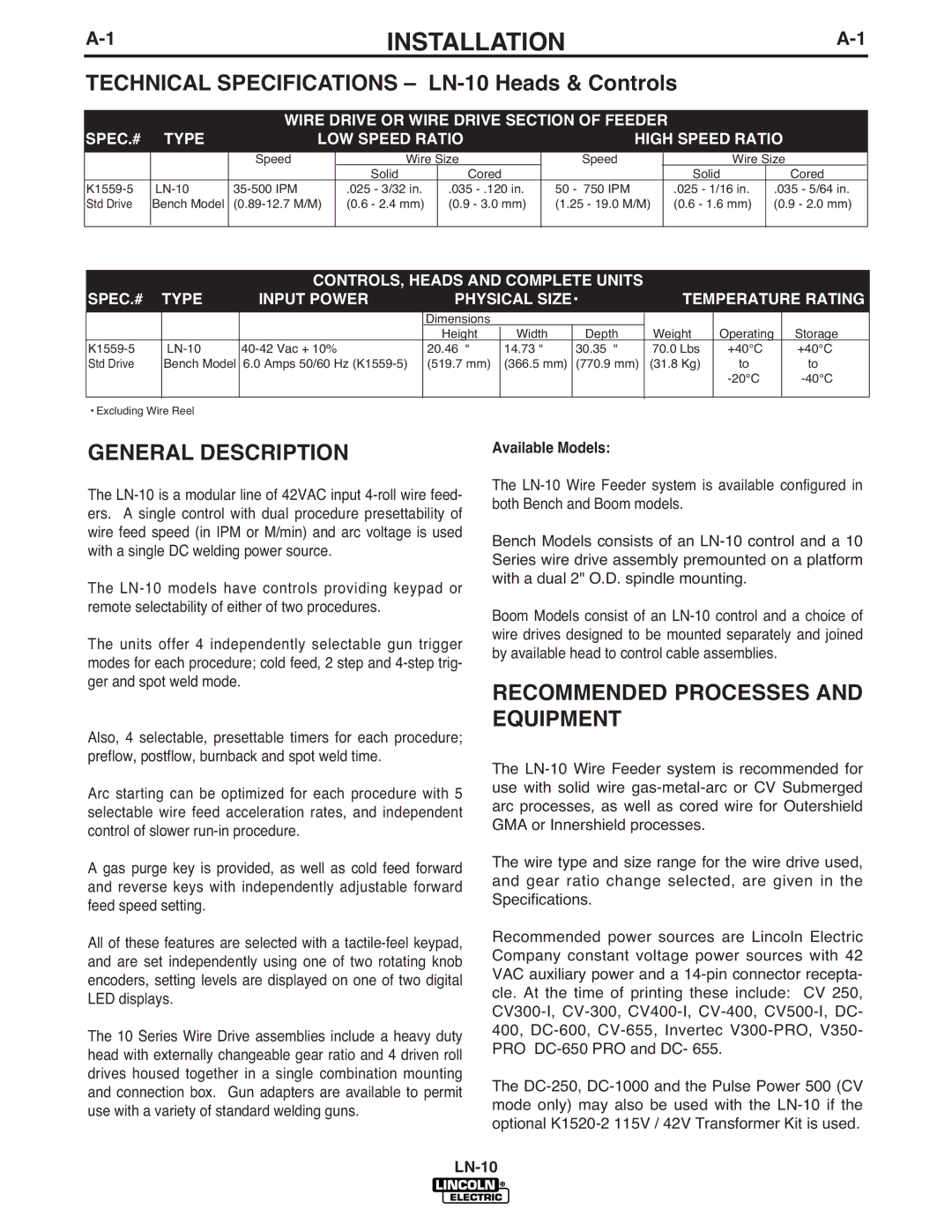

| WIRE DRIVE OR WIRE DRIVE SECTION OF FEEDER |

|

|

|

| |||||||||||||||

|

| LOW SPEED RATIO |

|

|

| HIGH SPEED RATIO |

| ||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Speed |

| Wire Size |

|

|

| Speed |

|

|

| Wire Size |

| ||||||

|

|

|

|

|

|

|

| Solid |

| Cored |

|

|

|

|

|

| Solid |

| Cored |

| |||

|

| .025 - 3/32 in. |

| .035 |

| 50 - 750 IPM |

|

| .025 - 1/16 in. | .035 - 5/64 in. |

| ||||||||||||

| Std Drive | Bench Model |

| (0.6 - 2.4 mm) |

| (0.9 - 3.0 mm) |

| (1.25 - 19.0 M/M) | (0.6 - 1.6 mm) | (0.9 - 2.0 mm) |

| ||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||

| SPEC.# |

| TYPE |

| CONTROLS, HEADS AND COMPLETE UNITS |

|

| TEMPERATURE RATING |

| ||||||||||||||

|

|

| INPUT POWER |

| PHYSICAL SIZE• |

|

|

| |||||||||||||||

|

|

|

|

|

|

|

|

|

| Dimensions |

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

| Height |

| Width |

| Depth | Weight | Operating | Storage |

| ||||

|

|

|

|

| 20.46 “ |

| 14.73 “ |

| 30.35 “ | 70.0 Lbs | +40°C |

| +40°C |

| |||||||||

| Std Drive |

| Bench Model | 6.0 Amps 50/60 Hz |

| (519.7 mm) |

| (366.5 mm) | (770.9 mm) | (31.8 Kg) | to |

| to |

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Excluding Wire Reel

GENERAL DESCRIPTION

The

The

The units offer 4 independently selectable gun trigger modes for each procedure; cold feed, 2 step and

Also, 4 selectable, presettable timers for each procedure; preflow, postflow, burnback and spot weld time.

Arc starting can be optimized for each procedure with 5 selectable wire feed acceleration rates, and independent control of slower

A gas purge key is provided, as well as cold feed forward and reverse keys with independently adjustable forward feed speed setting.

All of these features are selected with a

The 10 Series Wire Drive assemblies include a heavy duty head with externally changeable gear ratio and 4 driven roll drives housed together in a single combination mounting and connection box. Gun adapters are available to permit use with a variety of standard welding guns.

Available Models:

The

Bench Models consists of an

Boom Models consist of an

RECOMMENDED PROCESSES AND EQUIPMENT

The

The wire type and size range for the wire drive used, and gear ratio change selected, are given in the Specifications.

Recommended power sources are Lincoln Electric Company constant voltage power sources with 42 VAC auxiliary power and a

The