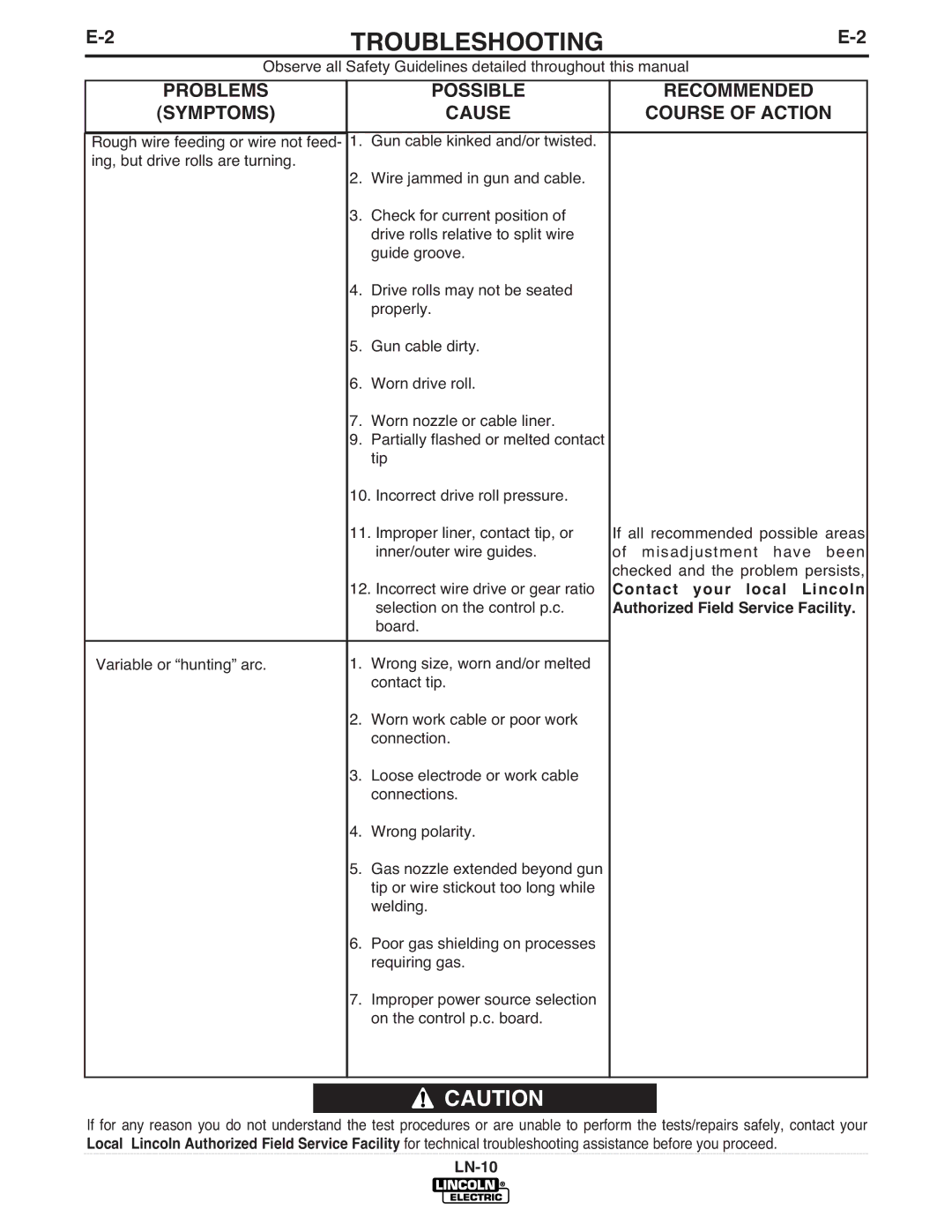

TROUBLESHOOTING | ||

Observe all Safety Guidelines detailed throughout this manual | ||

|

|

|

PROBLEMS | POSSIBLE | RECOMMENDED |

(SYMPTOMS) | CAUSE | COURSE OF ACTION |

Rough wire feeding or wire not feed- 1. Gun cable kinked and/or twisted. ing, but drive rolls are turning.

2.Wire jammed in gun and cable.

3.Check for current position of drive rolls relative to split wire guide groove.

4.Drive rolls may not be seated properly.

5.Gun cable dirty.

6.Worn drive roll.

7.Worn nozzle or cable liner.

9.Partially flashed or melted contact tip

10.Incorrect drive roll pressure.

| 11. Improper liner, contact tip, or | If all recommended possible areas | |

|

| inner/outer wire guides. | of misadjustment have been |

|

|

| checked and the problem persists, |

| 12. Incorrect wire drive or gear ratio | Contact your local Lincoln | |

|

| selection on the control p.c. | Authorized Field Service Facility. |

|

| board. |

|

|

|

|

|

Variable or “hunting” arc. | 1. | Wrong size, worn and/or melted |

|

|

| contact tip. |

|

| 2. | Worn work cable or poor work |

|

|

| connection. |

|

| 3. | Loose electrode or work cable |

|

|

| connections. |

|

| 4. | Wrong polarity. |

|

| 5. | Gas nozzle extended beyond gun |

|

|

| tip or wire stickout too long while |

|

|

| welding. |

|

| 6. | Poor gas shielding on processes |

|

|

| requiring gas. |

|

| 7. | Improper power source selection |

|

|

| on the control p.c. board. |

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.