12 | Stove Installation (for qualified installers only) |

Chimney Requirements

•DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

•UL 103 HT Chimney must be used from the first ceiling or floor penetration to the chimney cap.

•Use 6" diameter type UL 103 HT chimney from one manufacturer (do not mix brands) or code approved masonry chimney with a flue liner.

•Chimney must be fastened to each adjoining section.

•Follow the chimney manufacturer's clearances and requirements.

•Use the chimney manufacturer's fire stops, attic guards, roof supports, and flashings when passing through a ceiling

•No more than 180o of elbows (two 90o elbows, or two 45o & one 90o elbow, etc.) may be used for the entire system (connector and chimney).

NOTE: Additional elbows may be allowed if draft is sufficient. Whenever elbows are used the draft is adversely affected. Additional chimney height may be required to boost draft.

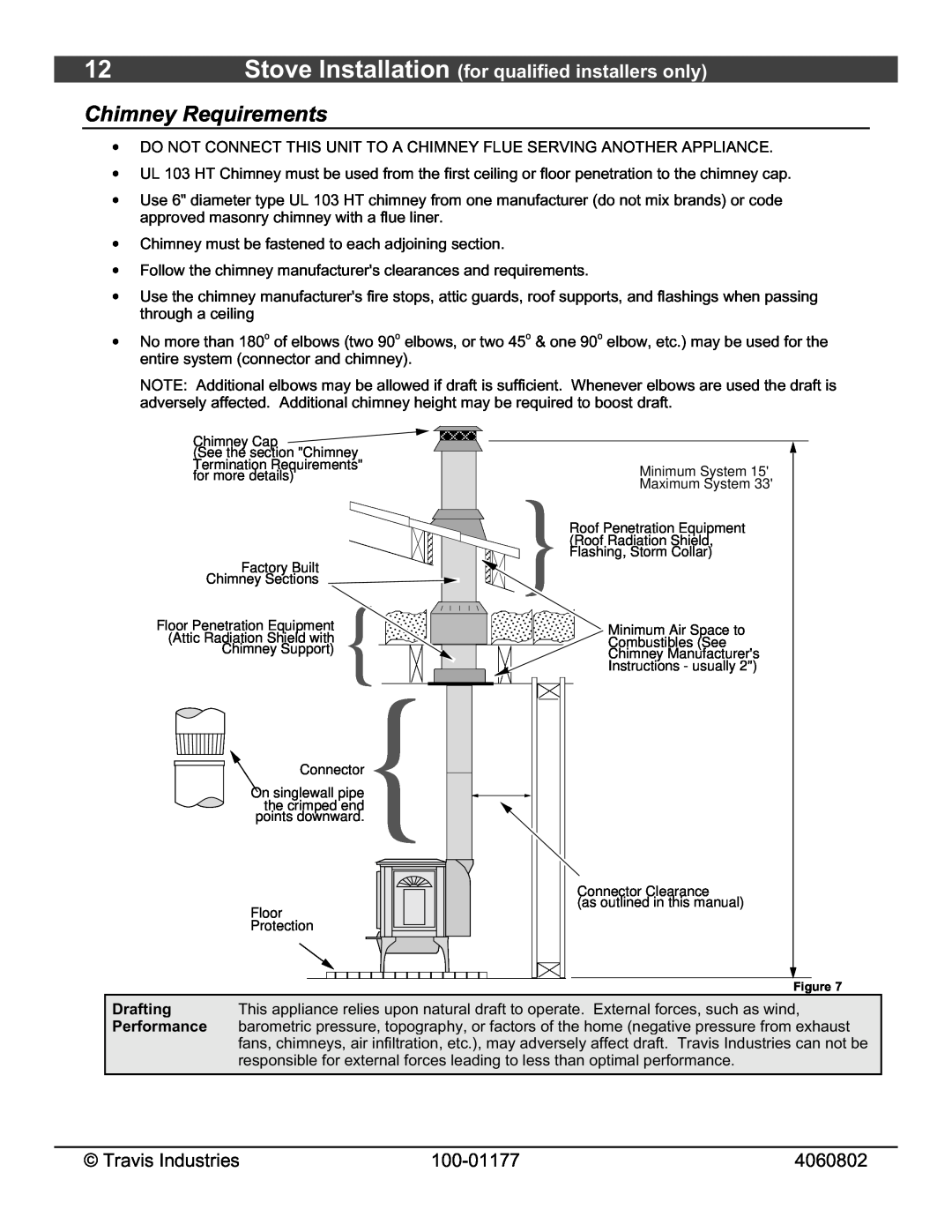

Chimney Cap ![]() (See the section "Chimney Termination Requirements"

(See the section "Chimney Termination Requirements"

for more details)

Factory Built Chimney Sections ![]()

Floor Penetration Equipment

(Attic Radiation Shield with

Chimney Support)

Connector} On singlewall pipe

the crimped end points downward.

Floor

Protection

Minimum System 15'

Maximum System 33'

}Roof Penetration Equipment (Roof Radiation Shield, Flashing, Storm Collar)

Minimum Air Space to

Combustibles (See

Chimney Manufacturer's

Instructions - usually 2")

Connector Clearance

(as outlined in this manual)

| Figure 7 |

Drafting | This appliance relies upon natural draft to operate. External forces, such as wind, |

Performance | barometric pressure, topography, or factors of the home (negative pressure from exhaust |

| fans, chimneys, air infiltration, etc.), may adversely affect draft. Travis Industries can not be |

| responsible for external forces leading to less than optimal performance. |

|

|

© Travis Industries | 4060802 |