P 3/ 20

Repair

Repair

[2]LUBRICATIONS

[2]-2 Hammer section

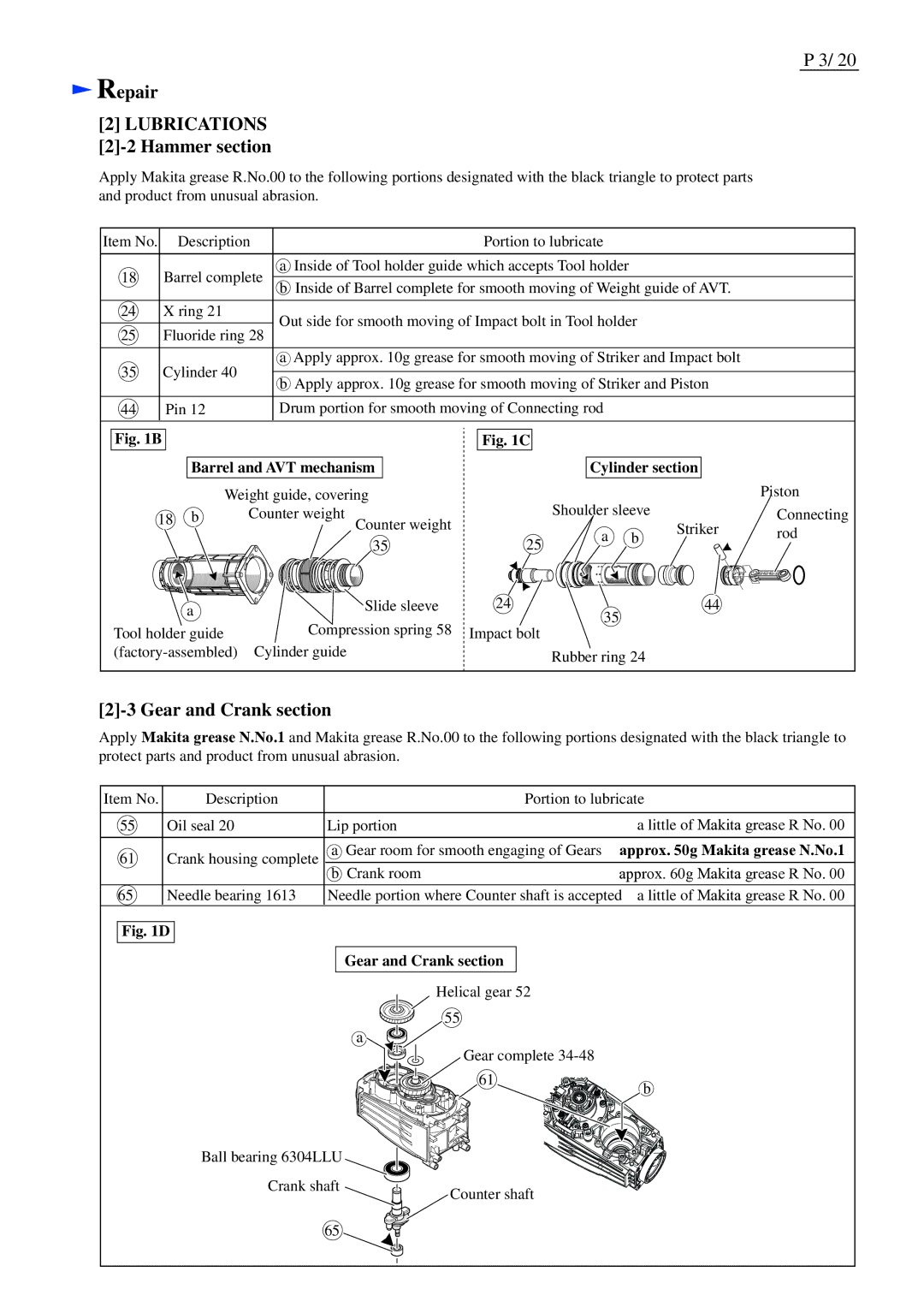

Apply Makita grease R.No.00 to the following portions designated with the black triangle to protect parts and product from unusual abrasion.

Item No. | Description | Portion to lubricate | ||

|

|

|

| |

18 | Barrel complete | a Inside of Tool holder guide which accepts Tool holder | ||

|

| |||

b Inside of Barrel complete for smooth moving of Weight guide of AVT. | ||||

|

| |||

|

|

|

| |

24 | X ring 21 | Out side for smooth moving of Impact bolt in Tool holder | ||

|

| |||

25 | Fluoride ring 28 | |||

|

| |||

|

|

|

| |

35 | Cylinder 40 | a Apply approx. 10g grease for smooth moving of Striker and Impact bolt | ||

|

| |||

b Apply approx. 10g grease for smooth moving of Striker and Piston | ||||

|

| |||

|

|

|

| |

44 | Pin 12 | Drum portion for smooth moving of Connecting rod | ||

|

|

|

| |

Fig. 1B

Barrel and AVT mechanism

Cylinder section

Weight guide, covering |

| Shoulder sleeve |

| Piston | |||

18 b | Counter weight | Counter weight |

|

| Connecting | ||

|

|

| Striker | ||||

|

|

| a | b | rod | ||

|

| 35 | 25 | ||||

|

|

| |||||

|

|

|

|

|

| ||

a |

| Slide sleeve | 24 | 35 |

| 44 |

|

|

|

|

|

|

| ||

Tool holder guide | Compression spring 58 | Impact bolt |

|

|

| ||

|

|

|

| ||||

Cylinder guide |

|

| Rubber ring 24 |

|

| ||

|

|

|

|

|

| ||

[2]-3 Gear and Crank section

Apply Makita grease N.No.1 and Makita grease R.No.00 to the following portions designated with the black triangle to protect parts and product from unusual abrasion.

Item No. | Description |

| Portion to lubricate | |

55 | Oil seal 20 | Lip portion |

| a little of Makita grease R No. 00 |

61 | Crank housing complete | a Gear room for smooth engaging of Gears | approx. 50g Makita grease N.No.1 | |

|

| b Crank room |

| approx. 60g Makita grease R No. 00 |

65 | Needle bearing 1613 | Needle portion where Counter shaft is accepted a little of Makita grease R No. 00 | ||

Fig. 1D |

|

|

| |

|

| Gear and Crank section |

| |

|

|

| Helical gear 52 |

|

|

|

| 55 |

|

|

| a |

|

|

|

|

| Gear complete |

|

|

|

| 61 | b |

|

|

|

| |

| Ball bearing 6304LLU |

|

| |

| Crank shaft | Counter shaft |

| |

|

|

|

| |

|

| 65 |

|

|