P 9/ 20

Repair

Repair

[3] DISASSEMBLY/ASSEMBLY

[3]-4. Bearing box section, Piston, Crank section

DISASSEMBLING

(1)Remove Handle section and Controller cover to hold the machine upright. (Fig. 2)

(2)Separate Barrel section from Crank housing complete (the left illustration in Fig. 6)

(3)Disassemble Cylinder section (Fig. 7)

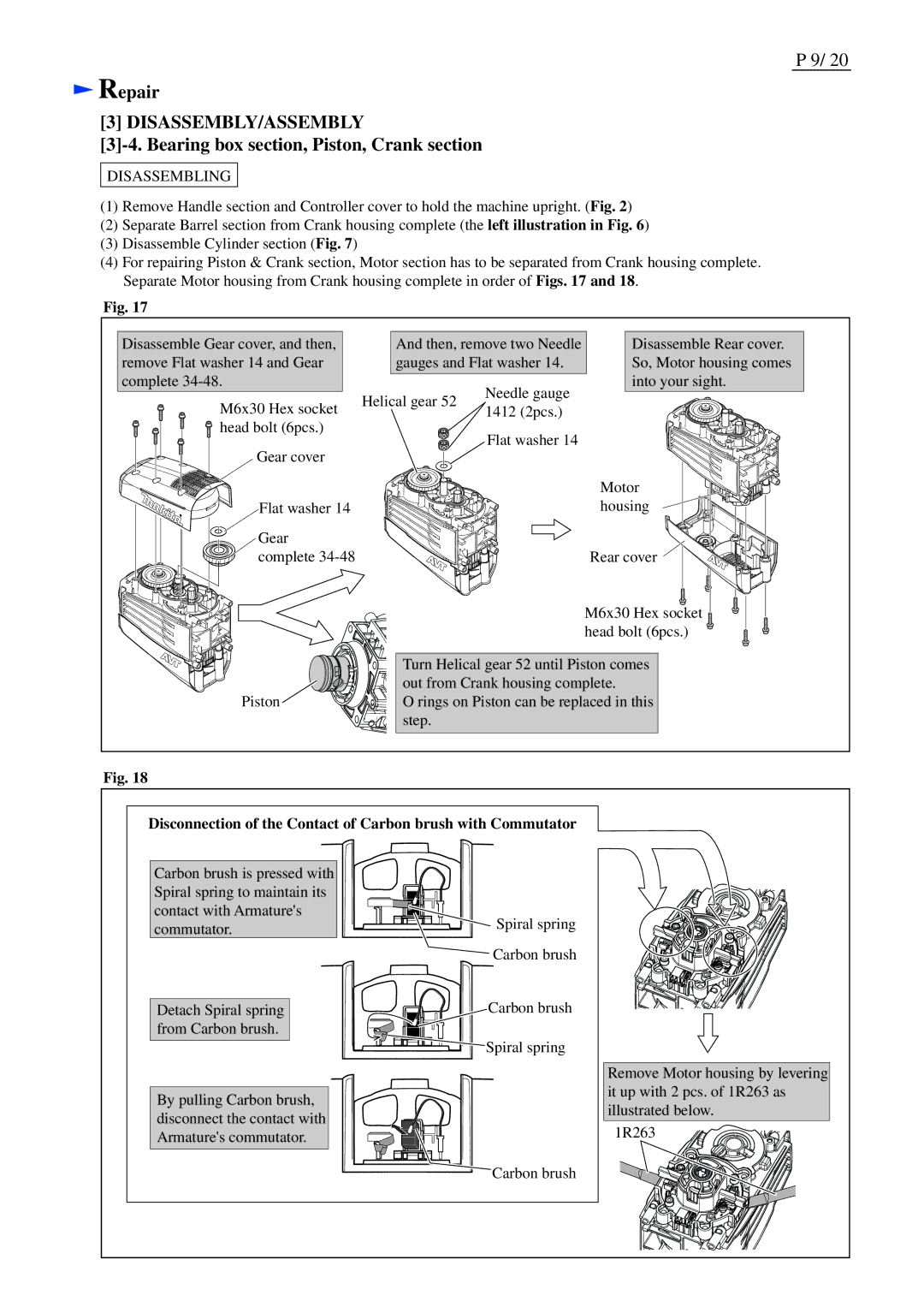

(4)For repairing Piston & Crank section, Motor section has to be separated from Crank housing complete. Separate Motor housing from Crank housing complete in order of Figs. 17 and 18.

Fig. 17

Disassemble Gear cover, and then, remove Flat washer 14 and Gear complete

M6x30 Hex socket

![]() head bolt (6pcs.)

head bolt (6pcs.)

Gear cover

Flat washer 14

Gear

![]() complete

complete

Piston![]()

And then, remove two Needle | Disassemble Rear cover. | |

gauges and Flat washer 14. | So, Motor housing comes | |

| Needle gauge | into your sight. |

Helical gear 52 |

| |

1412 (2pcs.) |

| |

|

| |

| Flat washer 14 |

|

Motor housing

Rear cover

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

M6x30 Hex socket ![]() head bolt (6pcs.)

head bolt (6pcs.) ![]()

Turn Helical gear 52 until Piston comes out from Crank housing complete.

O rings on Piston can be replaced in this step.

Fig. 18

Disconnection of the Contact of Carbon brush with Commutator

Carbon brush is pressed with Spiral spring to maintain its contact with Armature's commutator.

Detach Spiral spring from Carbon brush.

By pulling Carbon brush, disconnect the contact with Armature's commutator.

![]()

![]()

![]() Spiral spring Carbon brush

Spiral spring Carbon brush

Carbon brush

Spiral spring |

Carbon brush

Remove Motor housing by levering it up with 2 pcs. of 1R263 as illustrated below.

1R263