P 3 / 26

Repair

Repair

WARNING: Be sure to unplug the tool before maintenance or repair. See the instruction manual on how to handle the tool.

Remove the following parts from the machine for safety before repair/ maintenance: *Saw Blade *Inner Flange *Outer Flange *Dust Nozzle

[1] Lubrication

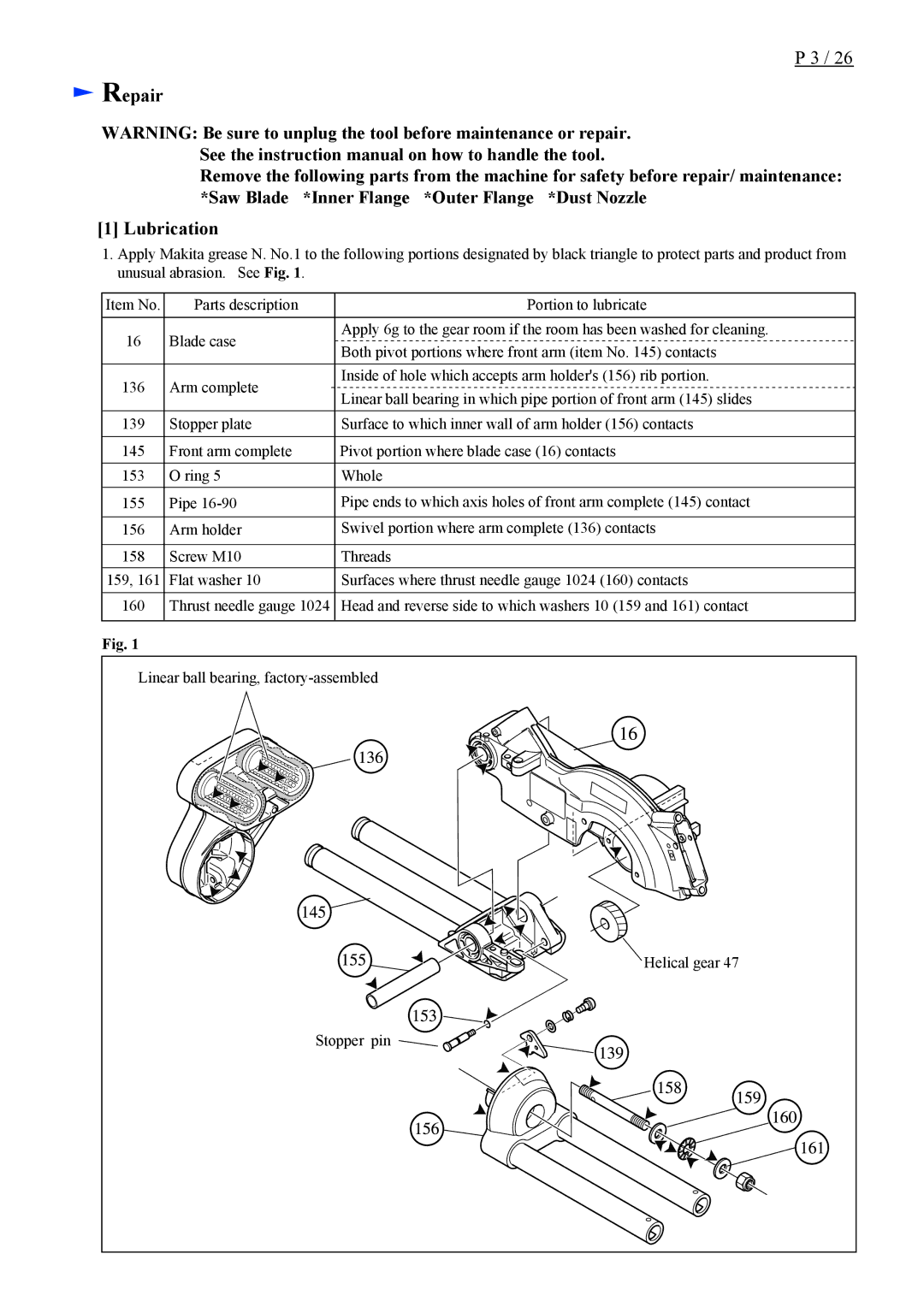

1.Apply Makita grease N. No.1 to the following portions designated by black triangle to protect parts and product from unusual abrasion. See Fig. 1.

Item No. | Parts description | Portion to lubricate | |

|

|

| |

16 | Blade case | Apply 6g to the gear room if the room has been washed for cleaning. | |

Both pivot portions where front arm (item No. 145) contacts | |||

|

| ||

|

|

| |

136 | Arm complete | Inside of hole which accepts arm holder's (156) rib portion. | |

Linear ball bearing in which pipe portion of front arm (145) slides | |||

|

| ||

|

|

| |

139 | Stopper plate | Surface to which inner wall of arm holder (156) contacts | |

|

|

| |

145 | Front arm complete | Pivot portion where blade case (16) contacts | |

|

|

| |

153 | O ring 5 | Whole | |

|

|

| |

155 | Pipe | Pipe ends to which axis holes of front arm complete (145) contact | |

|

|

| |

156 | Arm holder | Swivel portion where arm complete (136) contacts | |

|

|

| |

158 | Screw M10 | Threads | |

159, 161 | Flat washer 10 | Surfaces where thrust needle gauge 1024 (160) contacts | |

|

|

| |

160 | Thrust needle gauge 1024 | Head and reverse side to which washers 10 (159 and 161) contact | |

|

|

|

Fig. 1

Linear ball bearing, |

Helical gear 47 |

Stopper pin |