P 20/ 26

Repair

Repair

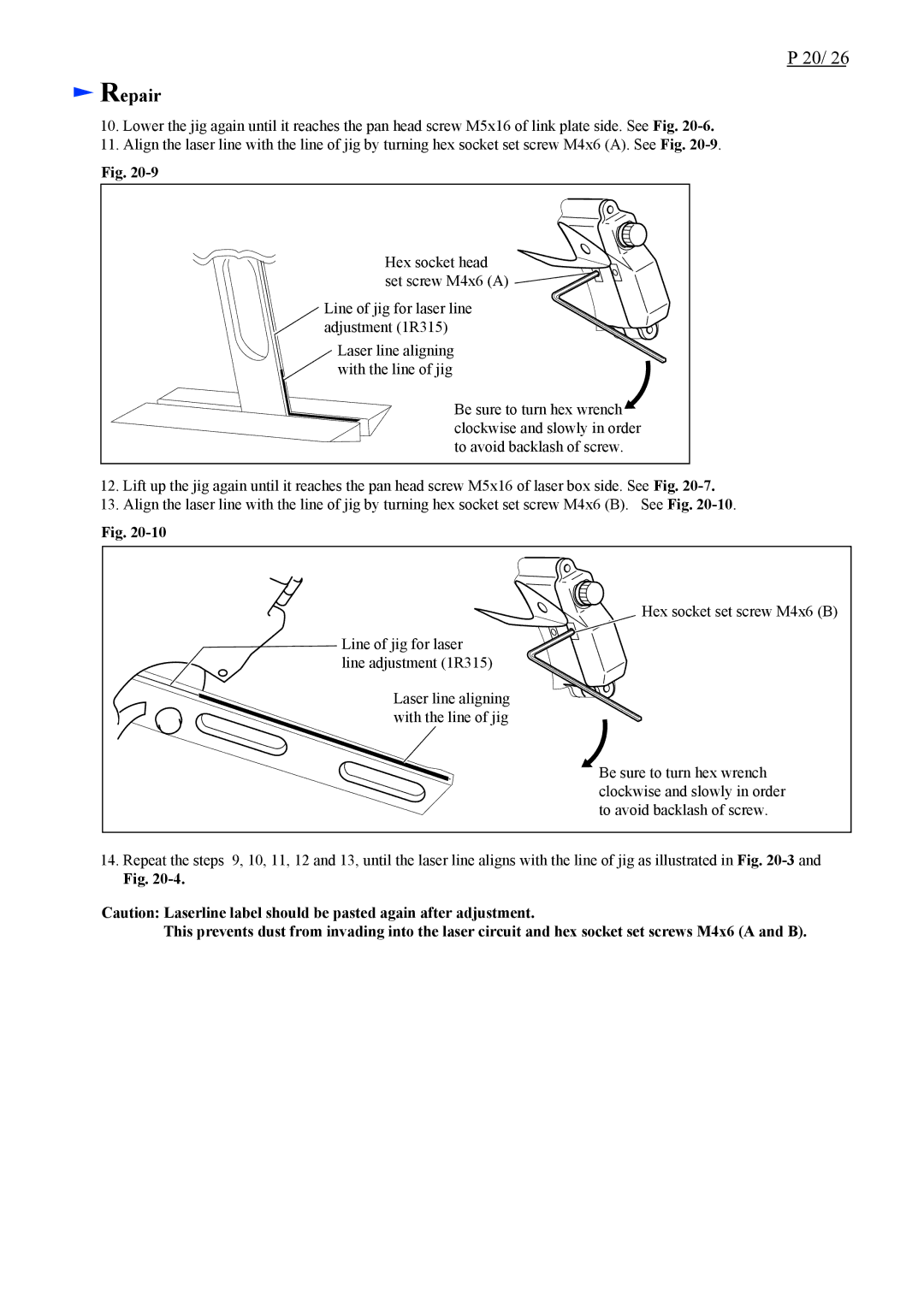

10.Lower the jig again until it reaches the pan head screw M5x16 of link plate side. See Fig.

11.Align the laser line with the line of jig by turning hex socket set screw M4x6 (A). See Fig.

Fig.

Hex socket head ![]()

![]() set screw M4x6 (A)

set screw M4x6 (A) ![]()

![]()

Line of jig for laser line adjustment (1R315)

Laser line aligning with the line of jig

Be sure to turn hex wrench clockwise and slowly in order to avoid backlash of screw.

12.Lift up the jig again until it reaches the pan head screw M5x16 of laser box side. See Fig.

13.Align the laser line with the line of jig by turning hex socket set screw M4x6 (B). See Fig.

Fig.

Hex socket set screw M4x6 (B)

Line of jig for laser line adjustment (1R315)

Laser line aligning with the line of jig

Be sure to turn hex wrench clockwise and slowly in order to avoid backlash of screw.

14.Repeat the steps 9, 10, 11, 12 and 13, until the laser line aligns with the line of jig as illustrated in Fig.

Fig.

Caution: Laserline label should be pasted again after adjustment.

This prevents dust from invading into the laser circuit and hex socket set screws M4x6 (A and B).