P 7 / 26

Repair

Repair

[5]Adjusting the return force of torsion spring 28

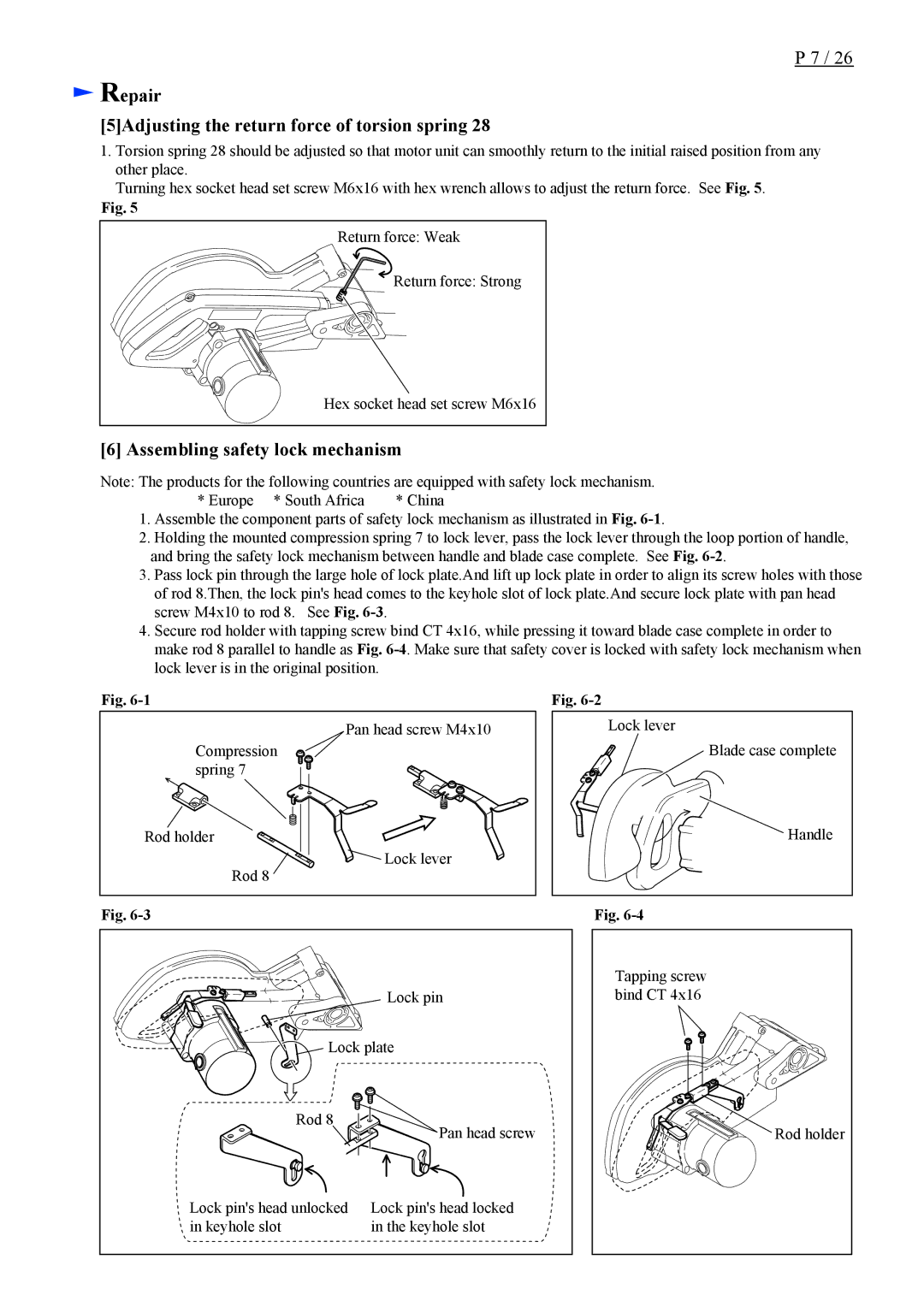

1.Torsion spring 28 should be adjusted so that motor unit can smoothly return to the initial raised position from any other place.

Turning hex socket head set screw M6x16 with hex wrench allows to adjust the return force. See Fig. 5.

Fig. 5

Return force: Weak

![]()

![]()

![]()

![]() Return force: Strong

Return force: Strong

Hex socket head set screw M6x16

[6] Assembling safety lock mechanism

Note: The products for the following countries are equipped with safety lock mechanism.

* Europe * South Africa | * China |

1.Assemble the component parts of safety lock mechanism as illustrated in Fig.

2.Holding the mounted compression spring 7 to lock lever, pass the lock lever through the loop portion of handle, and bring the safety lock mechanism between handle and blade case complete. See Fig.

3.Pass lock pin through the large hole of lock plate.And lift up lock plate in order to align its screw holes with those of rod 8.Then, the lock pin's head comes to the keyhole slot of lock plate.And secure lock plate with pan head screw M4x10 to rod 8. See Fig.

4.Secure rod holder with tapping screw bind CT 4x16, while pressing it toward blade case complete in order to make rod 8 parallel to handle as Fig.

Fig. |

Pan head screw M4x10 |

Compression |

spring 7 |

Rod holder |

Lock lever |

Rod 8 |

Fig. |

Fig.

Lock lever

Blade case complete

![]()

![]() Handle

Handle

Fig.

Lock pin

![]()

![]() Lock plate

Lock plate

Rod 8 | Pan head screw |

|

Lock pin's head unlocked | Lock pin's head locked |

in keyhole slot | in the keyhole slot |

Tapping screw bind CT 4x16

Rod holder |