Ice Machine Operation | Section 3 |

|

|

Operational Checks

GENERAL

Manitowoc ice machines are

To ensure proper operation, always follow the Operational Checks:

•when starting the ice machine for the first time

•after a prolonged out of service period

•after cleaning and sanitizing

NOTE: Routine adjustments and maintenance procedures are not covered by the warranty.

WATER LEVEL

The water level sensor is set to maintain the proper water level above the water pump housing. The water level is not adjustable. If the water level is incorrect, check the water level probe for damage (probe bent, etc.). Clean the water level probe with ice machine cleaner, rinse thoroughly and

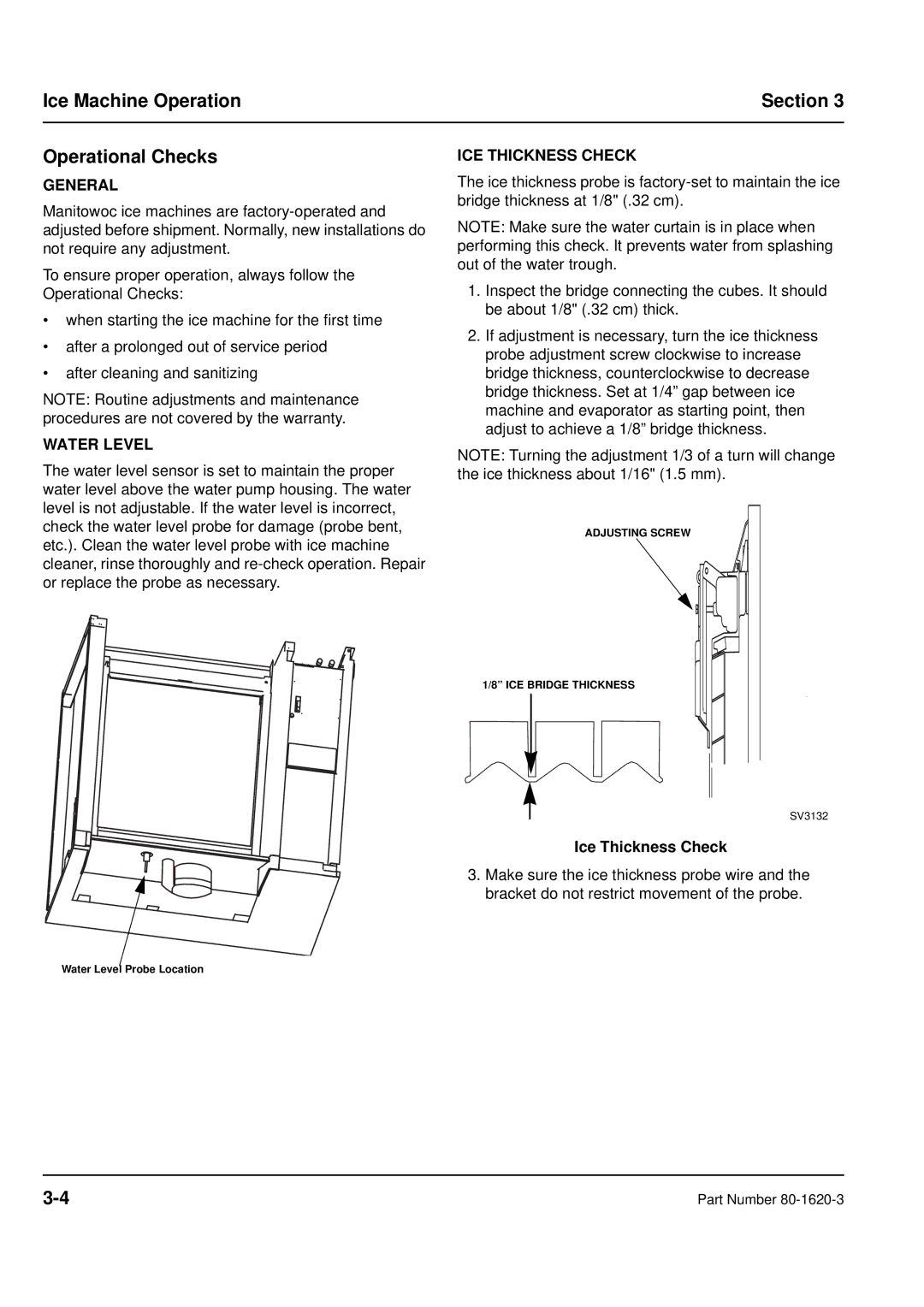

ICE THICKNESS CHECK

The ice thickness probe is

NOTE: Make sure the water curtain is in place when performing this check. It prevents water from splashing out of the water trough.

1.Inspect the bridge connecting the cubes. It should be about 1/8" (.32 cm) thick.

2.If adjustment is necessary, turn the ice thickness probe adjustment screw clockwise to increase bridge thickness, counterclockwise to decrease bridge thickness. Set at 1/4” gap between ice machine and evaporator as starting point, then adjust to achieve a 1/8” bridge thickness.

NOTE: Turning the adjustment 1/3 of a turn will change the ice thickness about 1/16" (1.5 mm).

ADJUSTING SCREW

1/8” ICE BRIDGE THICKNESS

SV3132

Ice Thickness Check

3.Make sure the ice thickness probe wire and the bracket do not restrict movement of the probe.

Water Level Probe Location

Part Number |