2 MAINTENANCE

| |

|

|

FOREWORD: Before entering any part of the compactor, be sure that all sources of energy have been shut off, all poten- tial hazards have been eliminated, and the compactor is

INSTRUCTIONS

1.Move the main disconnect lever to the OFF position.

2.Padlock the disconnect lever with a keyed padlock and take the key with you.

3.Along with the padlock, place an appropriate, highly visible, warning tag on the disconnect lever. The tag should provide a warning such as: “Danger: Do not operate equipment. Person working on equipment.” or

“Warning: Do not energize without the permission of ________________.”

4.After locking and tagging the compactor, try to start and operate the compactor (as outlined in the Operating Instructions) to make sure the

ELECTRICAL: The motor control panel contains high voltage components. Only authorized service person- nel should be allowed inside the panel. Authorized ser- vice personnel should be allowed inside the panel only after the compactor has been

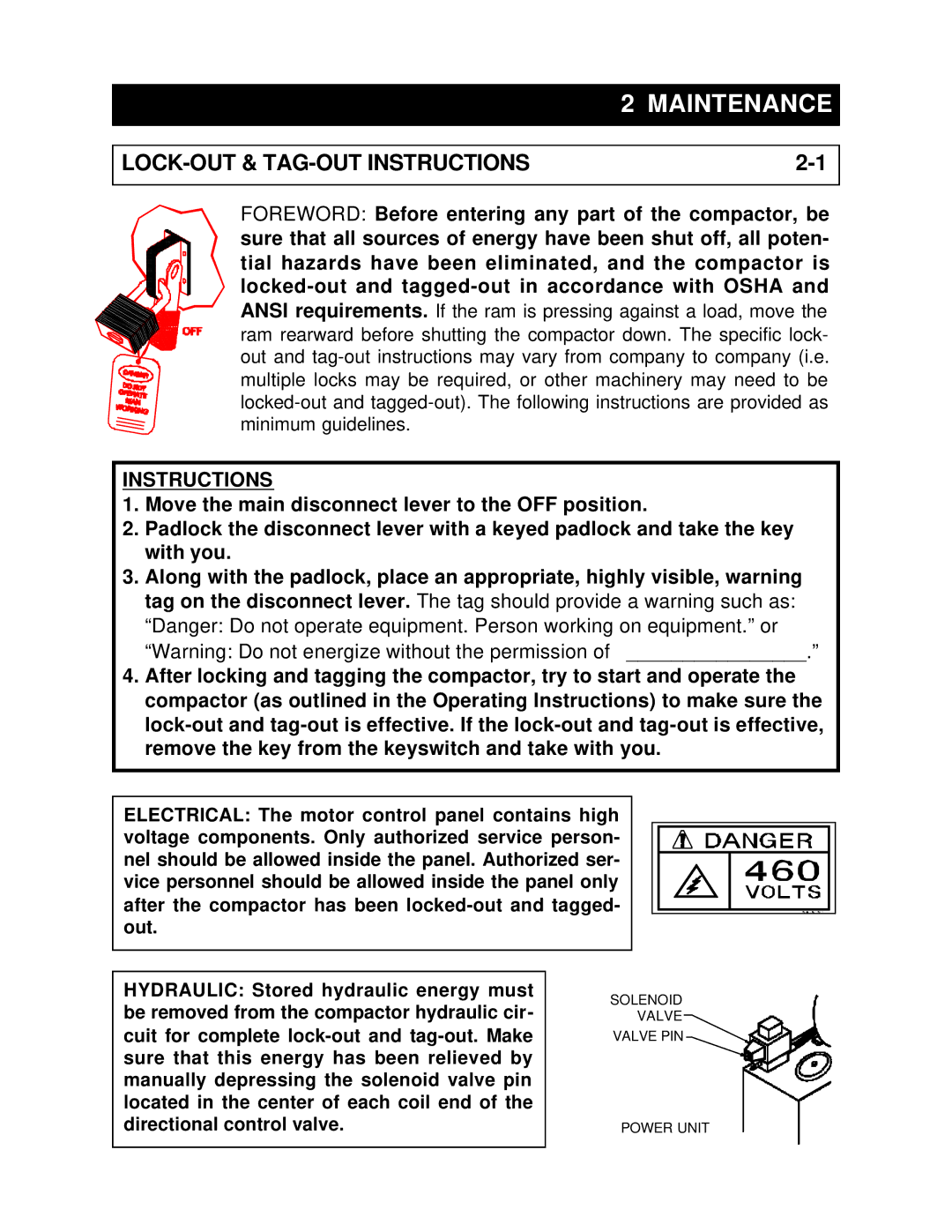

HYDRAULIC: Stored hydraulic energy must be removed from the compactor hydraulic cir- cuit for complete

SOLENOID

VALVE

VALVE PIN

POWER UNIT