. Complete Parts List available at www.MillerWelds.com

8-4. Adjusting Engine Speed (Kohler−Powered Units)

2500 ± 100 rpm (42 Hz)

3750 ± 30 rpm (62Hz)

After tuning engine, check engine speed. See table for proper no load speed. If necessary, adjust speed as follows:

Start engine and run until warm. Set Weld Output Control to Max.

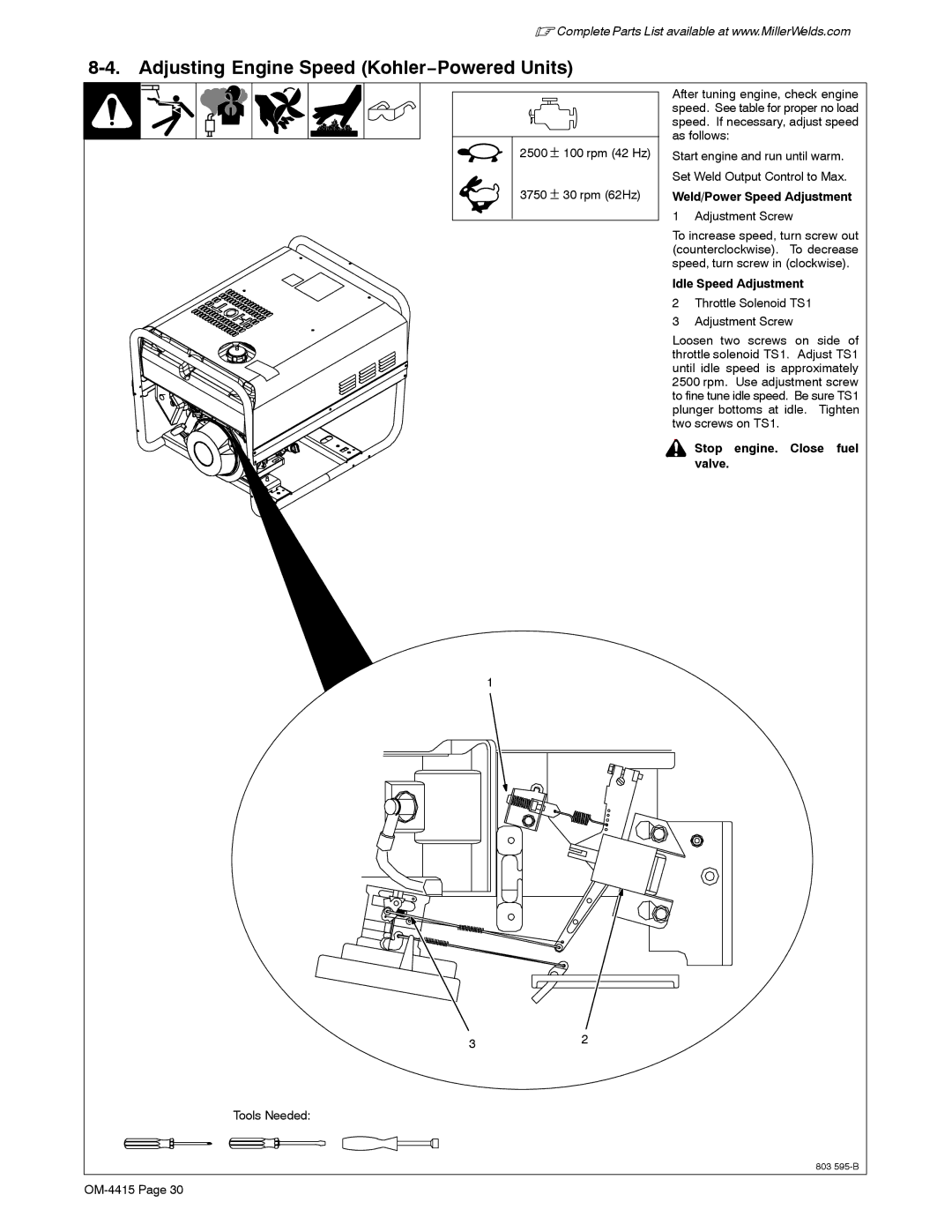

Weld/Power Speed Adjustment

1 Adjustment Screw

To increase speed, turn screw out (counterclockwise). To decrease speed, turn screw in (clockwise).

Idle Speed Adjustment

2Throttle Solenoid TS1

3Adjustment Screw

Loosen two screws on side of throttle solenoid TS1. Adjust TS1 until idle speed is approximately 2500 rpm. Use adjustment screw to fine tune idle speed. Be sure TS1 plunger bottoms at idle. Tighten two screws on TS1.

! Stop engine. Close fuel valve.

1

32

Tools Needed:

803