. Complete Parts List available at www.MillerWelds.com

8-3. Adjusting Engine Speed (Honda-Powered Units)

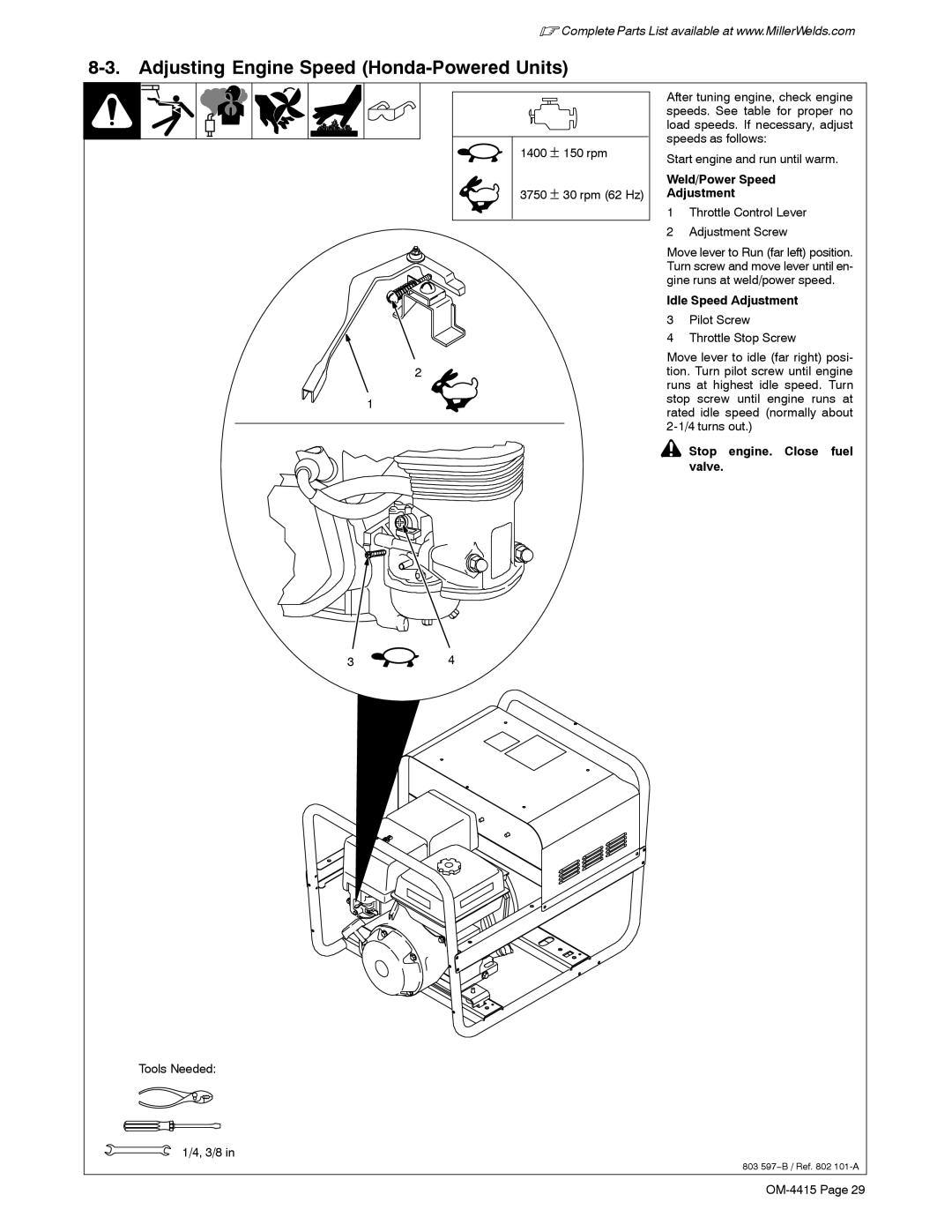

1400 ± 150 rpm

3750 ± 30 rpm (62 Hz)

2

1

After tuning engine, check engine speeds. See table for proper no load speeds. If necessary, adjust speeds as follows:

Start engine and run until warm.

Weld/Power Speed

Adjustment

1Throttle Control Lever

2Adjustment Screw

Move lever to Run (far left) position. Turn screw and move lever until en- gine runs at weld/power speed.

Idle Speed Adjustment

3Pilot Screw

4Throttle Stop Screw

Move lever to idle (far right) posi- tion. Turn pilot screw until engine runs at highest idle speed. Turn stop screw until engine runs at rated idle speed (normally about

! | Stop | engine. | Close | fuel |

| valve. |

|

|

|

3 ![]()

![]() 4

4

Tools Needed:

1/4, 3/8 in

803 597−B / Ref. 802