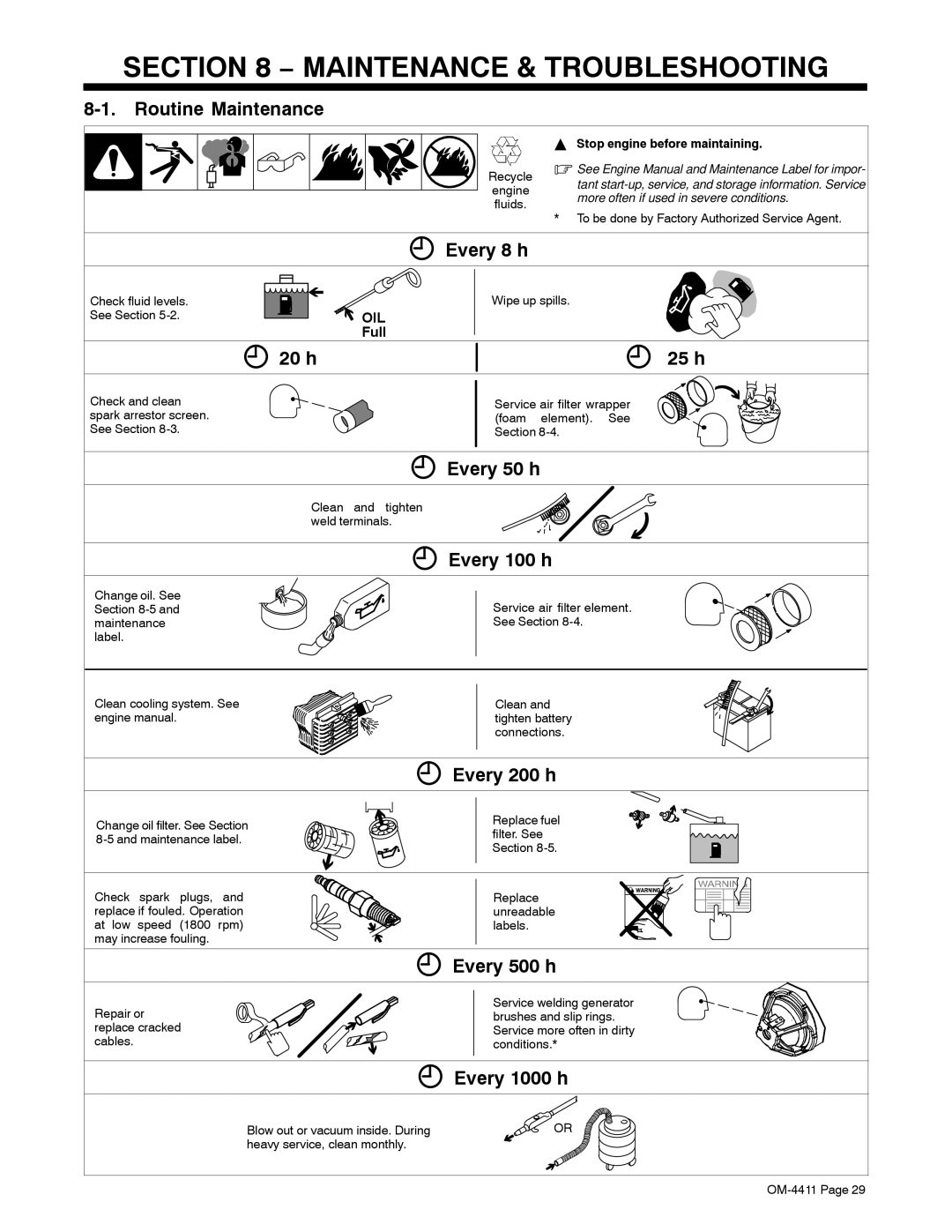

SECTION 8 − MAINTENANCE & TROUBLESHOOTING

8-1. Routine Maintenance

Recycle engine fluids.

YStop engine before maintaining.

.See Engine Manual and Maintenance Label for impor-

tant

*To be done by Factory Authorized Service Agent.

![]() Every 8 h

Every 8 h

Check fluid levels. See Section

![]() OIL Full

OIL Full

Wipe up spills.

20 h

20 h

25 h

Check and clean spark arrestor screen. See Section

Service air filter wrapper (foam element). See Section

| Every 50 h |

Clean and | tighten |

weld terminals. | |

| Every 100 h |

Change oil. See | Service air filter element. |

Section | |

maintenance | See Section |

label.

Clean cooling system. See engine manual.

Clean and tighten battery connections.

Every 200 h

Every 200 h

Change oil filter. See Section

Replace fuel filter. See Section

Check spark plugs, and replace if fouled. Operation at low speed (1800 rpm) may increase fouling.

Replace unreadable labels.

Repair or replace cracked cables.

![]() Every 500 h

Every 500 h

Service welding generator brushes and slip rings. Service more often in dirty conditions.*

![]() Every 1000 h

Every 1000 h

Blow out or vacuum inside. During | OR |

heavy service, clean monthly. |

|