SECTION 5 – OPERATING THE WELDING GENERATOR

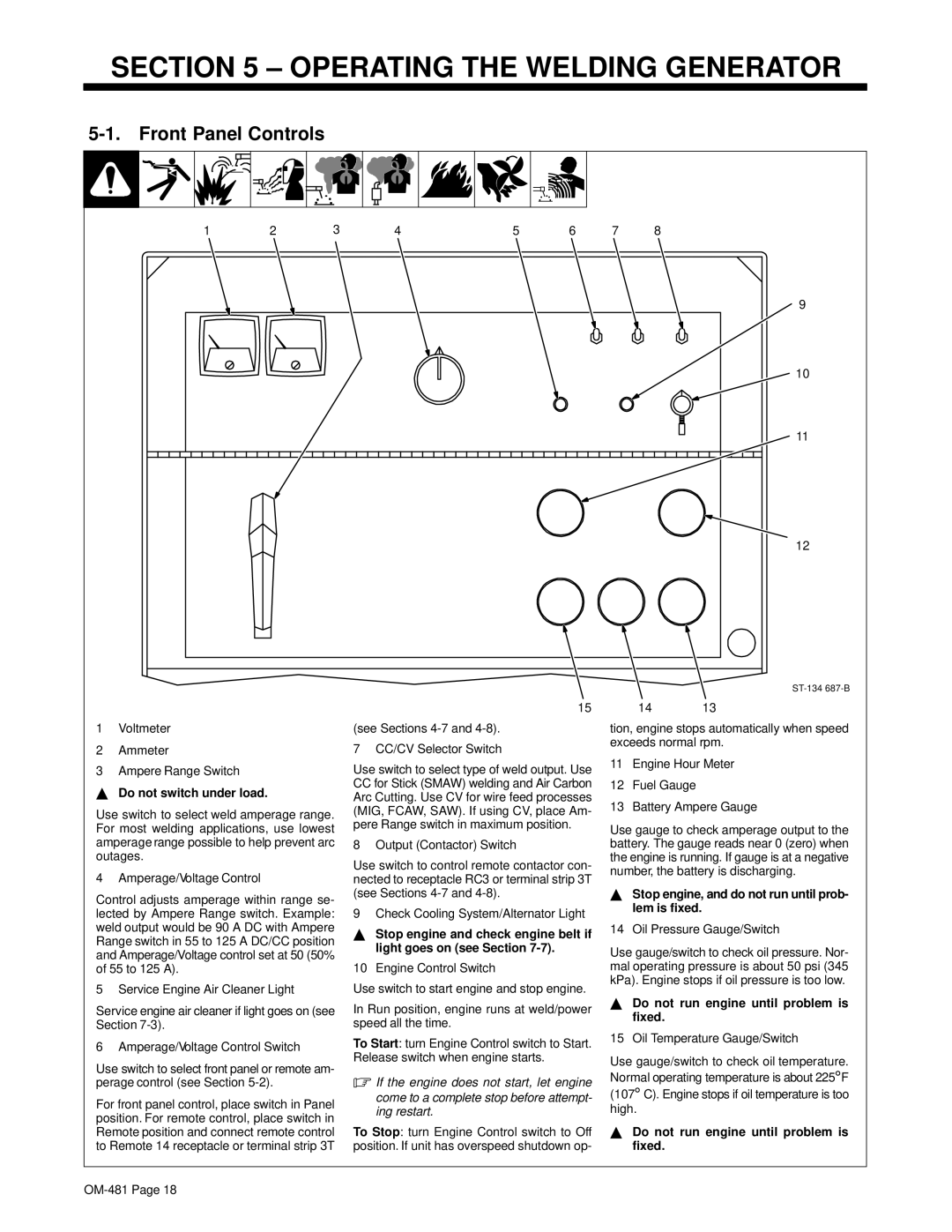

5-1. Front Panel Controls

1 2 3

1Voltmeter

2Ammeter

3Ampere Range Switch

YDo not switch under load.

Use switch to select weld amperage range. For most welding applications, use lowest amperage range possible to help prevent arc outages.

4 Amperage/Voltage Control

Control adjusts amperage within range se- lected by Ampere Range switch. Example: weld output would be 90 A DC with Ampere Range switch in 55 to 125 A DC/CC position and Amperage/Voltage control set at 50 (50% of 55 to 125 A).

5 Service Engine Air Cleaner Light

Service engine air cleaner if light goes on (see Section

6 Amperage/Voltage Control Switch

Use switch to select front panel or remote am- perage control (see Section

For front panel control, place switch in Panel position. For remote control, place switch in Remote position and connect remote control to Remote 14 receptacle or terminal strip 3T

4 | 5 | 6 |

15

(see Sections 4-7 and 4-8).

7 CC/CV Selector Switch

Use switch to select type of weld output. Use

CCfor Stick (SMAW) welding and Air Carbon Arc Cutting. Use CV for wire feed processes (MIG, FCAW, SAW). If using CV, place Am- pere Range switch in maximum position.

8 Output (Contactor) Switch

Use switch to control remote contactor con- nected to receptacle RC3 or terminal strip 3T (see Sections

9 Check Cooling System/Alternator Light

YStop engine and check engine belt if light goes on (see Section

10 Engine Control Switch

Use switch to start engine and stop engine.

In Run position, engine runs at weld/power speed all the time.

To Start: turn Engine Control switch to Start. Release switch when engine starts.

.If the engine does not start, let engine come to a complete stop before attempt- ing restart.

To Stop: turn Engine Control switch to Off position. If unit has overspeed shutdown op-

7 8

9

10

11

12

14 13

tion, engine stops automatically when speed exceeds normal rpm.

11Engine Hour Meter

12Fuel Gauge

13Battery Ampere Gauge

Use gauge to check amperage output to the battery. The gauge reads near 0 (zero) when the engine is running. If gauge is at a negative number, the battery is discharging.

YStop engine, and do not run until prob- lem is fixed.

14 Oil Pressure Gauge/Switch

Use gauge/switch to check oil pressure. Nor- mal operating pressure is about 50 psi (345 kPa). Engine stops if oil pressure is too low.

YDo not run engine until problem is fixed.

15 Oil Temperature Gauge/Switch

Use gauge/switch to check oil temperature. Normal operating temperature is about 225° F (107° C). Engine stops if oil temperature is too high.

YDo not run engine until problem is fixed.