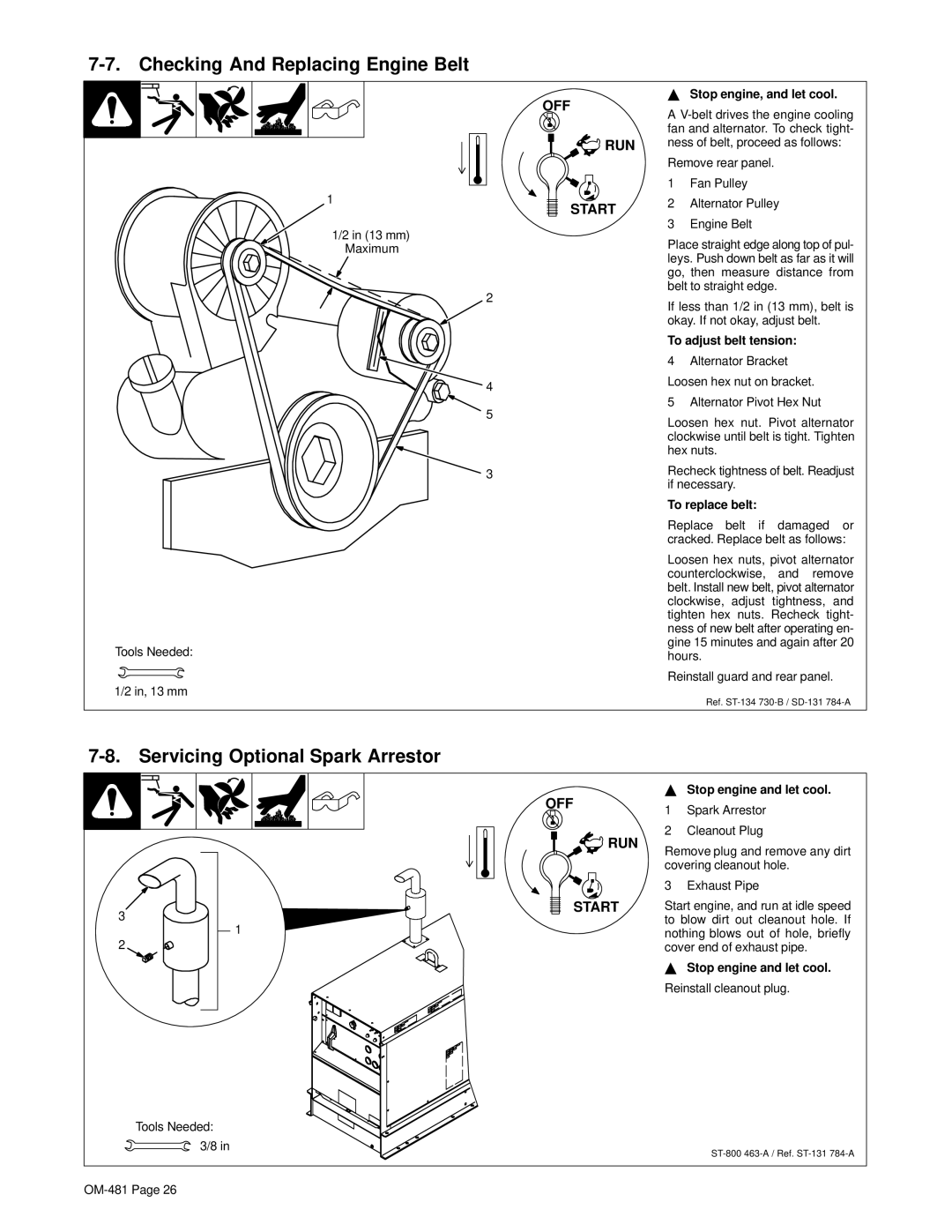

7-7. Checking And Replacing Engine Belt

OFF

![]() RUN

RUN

1

START

1/2 in (13 mm) Maximum

2

4

5

3

Tools Needed:

1/2 in, 13 mm

YStop engine, and let cool.

A

Remove rear panel.

1Fan Pulley

2Alternator Pulley

3Engine Belt

Place straight edge along top of pul- leys. Push down belt as far as it will go, then measure distance from belt to straight edge.

If less than 1/2 in (13 mm), belt is okay. If not okay, adjust belt.

To adjust belt tension:

4 Alternator Bracket

Loosen hex nut on bracket.

5 Alternator Pivot Hex Nut

Loosen hex nut. Pivot alternator clockwise until belt is tight. Tighten hex nuts.

Recheck tightness of belt. Readjust if necessary.

To replace belt:

Replace belt if damaged or cracked. Replace belt as follows:

Loosen hex nuts, pivot alternator counterclockwise, and remove belt. Install new belt, pivot alternator clockwise, adjust tightness, and tighten hex nuts. Recheck tight- ness of new belt after operating en- gine 15 minutes and again after 20 hours.

Reinstall guard and rear panel.

Ref.

7-8. Servicing Optional Spark Arrestor

OFF

YStop engine and let cool.

1 | Spark Arrestor |

2 | Cleanout Plug |

3

RUN

RUN

START

Remove plug and remove any dirt covering cleanout hole.

3 Exhaust Pipe

Start engine, and run at idle speed to blow dirt out cleanout hole. If

1

2

nothing blows out of hole, briefly cover end of exhaust pipe.

YStop engine and let cool.

Reinstall cleanout plug.

Tools Needed:

3/8 in