1

2

![]() 7

7

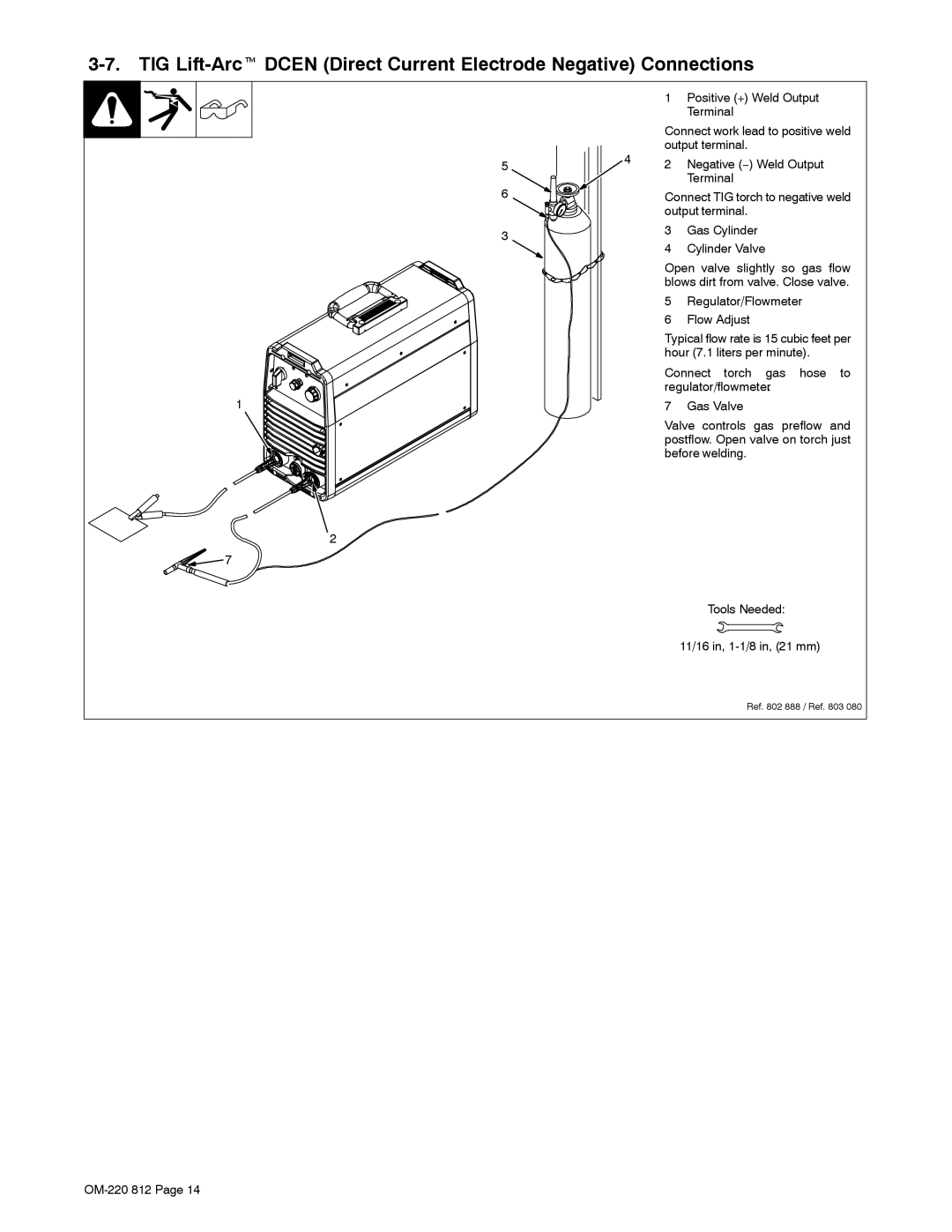

1Positive (+) Weld Output Terminal

|

| Connect work lead to positive weld | ||

| 4 | output terminal. | ||

5 | 2 | Negative (−) Weld Output | ||

| ||||

|

|

| Terminal | |

6 |

| Connect TIG torch to negative weld | ||

|

| output terminal. | ||

3 |

| 3 | Gas Cylinder | |

| 4 | Cylinder Valve | ||

|

| |||

Open valve slightly so gas flow blows dirt from valve. Close valve.

5Regulator/Flowmeter

6Flow Adjust

Typical flow rate is 15 cubic feet per hour (7.1 liters per minute).

Connect torch gas hose to regulator/flowmeter.

7 Gas Valve

Valve controls gas preflow and postflow. Open valve on torch just before welding.

Tools Needed:

11/16 in,

Ref. 802 888 / Ref. 803 080