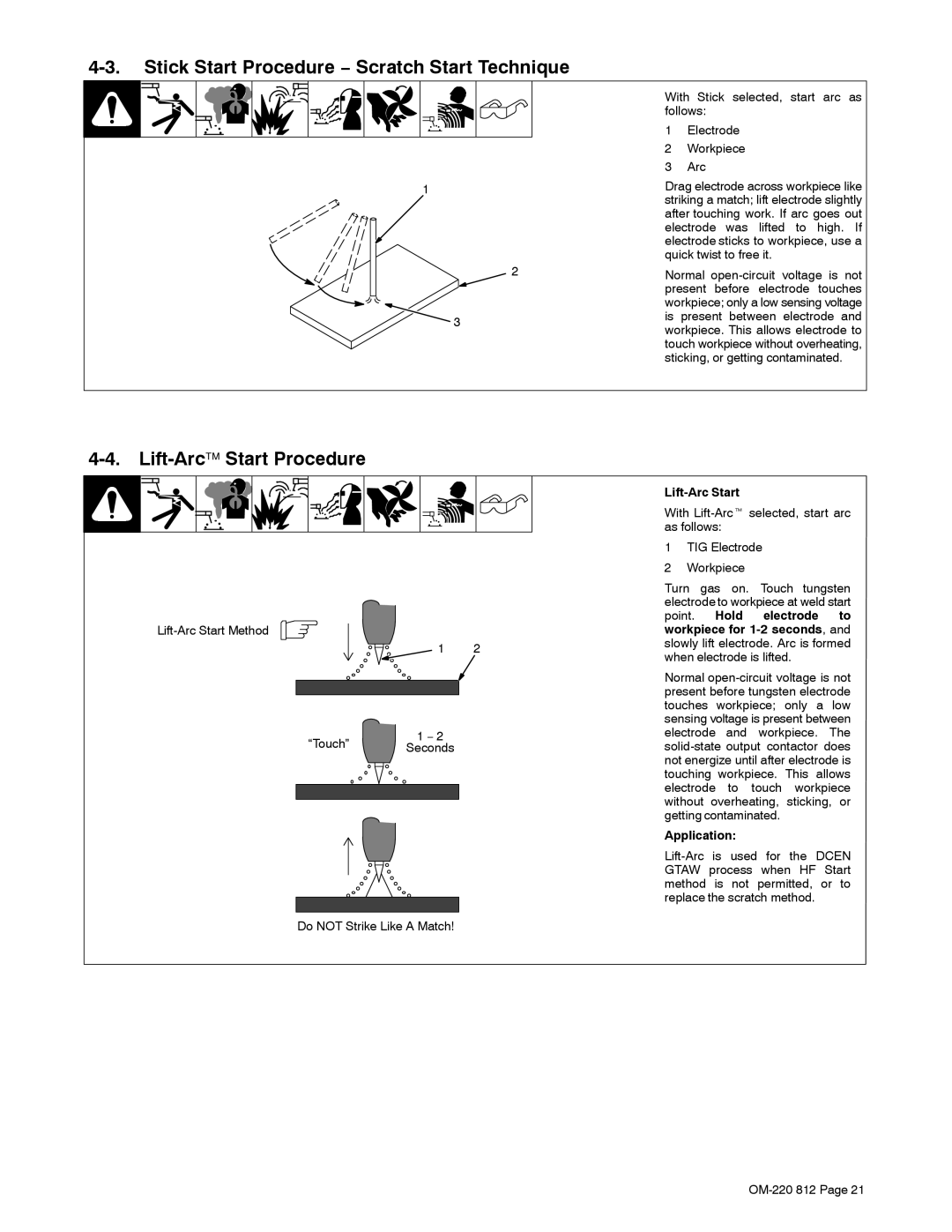

4-3. Stick Start Procedure − Scratch Start Technique

1

2

![]() 3

3

With Stick selected, start arc as follows:

1Electrode

2Workpiece

3Arc

Drag electrode across workpiece like striking a match; lift electrode slightly after touching work. If arc goes out electrode was lifted to high. If electrode sticks to workpiece, use a quick twist to free it.

Normal

4-4. Lift-Arc™ Start Procedure

1 2

“Touch” | 1 − 2 | |

Seconds | ||

| ||

|

| |

|

|

Do NOT Strike Like A Match!

Lift-Arc Start

With

1TIG Electrode

2Workpiece

Turn gas on. Touch tungsten electrode to workpiece at weld start point. Hold electrode to workpiece for

Normal