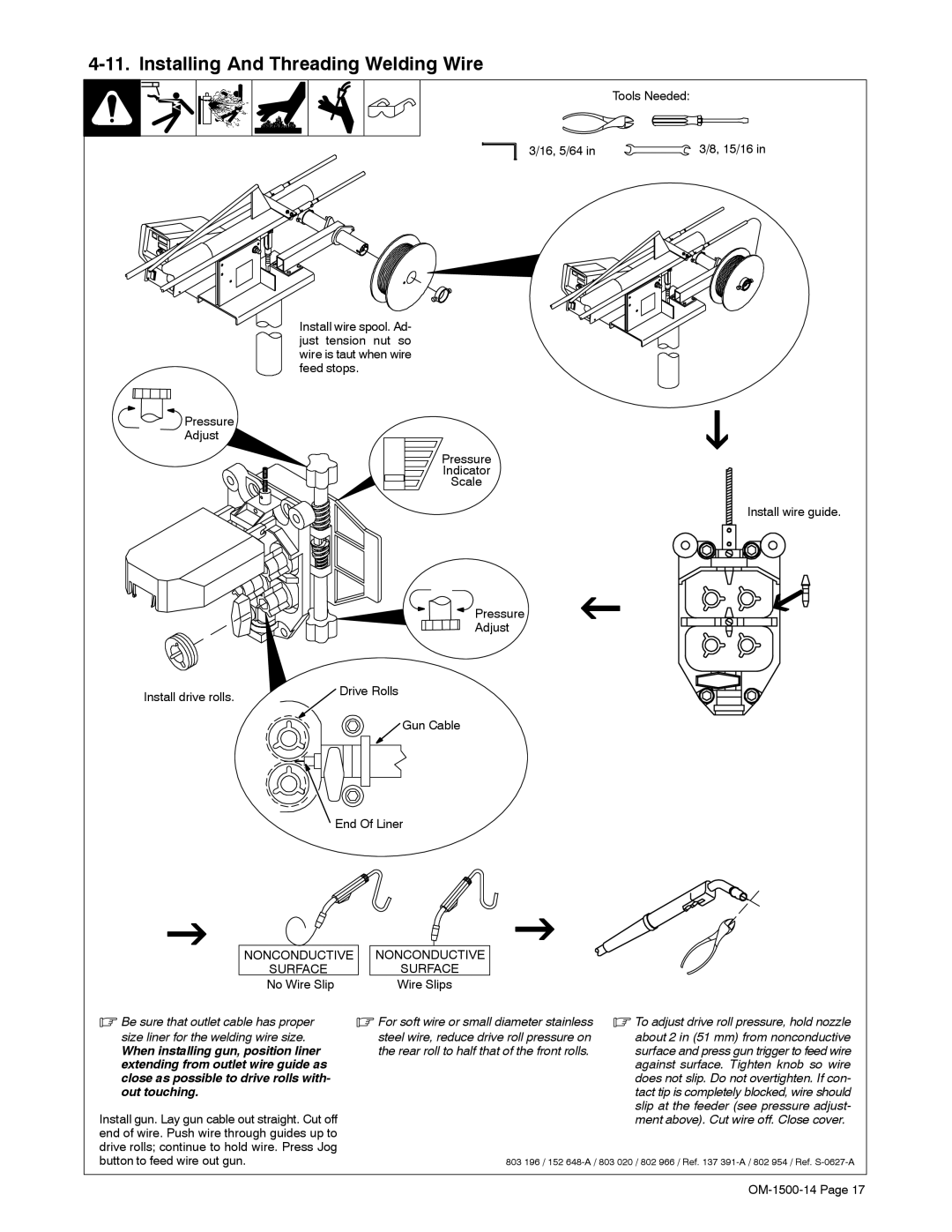

4-11. Installing And Threading Welding Wire

Tools Needed:

3/16, 5/64 in | 3/8, 15/16 in |

Pressure

Adjust

Install drive rolls.

Install wire spool. Ad- just tension nut so wire is taut when wire feed stops.

Pressure

Indicator

Scale

Install wire guide.

![]() Pressure

Pressure

Adjust

![]() Drive Rolls

Drive Rolls

![]() Gun Cable

Gun Cable

End Of Liner

| NONCONDUCTIVE |

| NONCONDUCTIVE |

|

| SURFACE |

| SURFACE |

|

| No Wire Slip |

| Wire Slips |

|

. Be sure that outlet cable has proper | . For soft wire or small diameter stainless | . To adjust drive roll pressure, hold nozzle | ||

size liner for the welding wire size. |

| steel wire, reduce drive roll pressure on | about 2 in (51 mm) from nonconductive | |

When installing gun, position liner |

| the rear roll to half that of the front rolls. | surface and press gun trigger to feed wire | |

extending from outlet wire guide as |

|

| against surface. Tighten knob so wire | |

close as possible to drive rolls with- |

|

| does not slip. Do not overtighten. If con- | |

out touching. |

|

| tact tip is completely blocked, wire should | |

Install gun. Lay gun cable out straight. Cut off |

|

| slip at the feeder (see pressure adjust- | |

|

| ment above). Cut wire off. Close cover. | ||

end of wire. Push wire through guides up to |

|

|

| |

drive rolls; continue to hold wire. Press Jog |

|

|

| |

button to feed wire out gun. |

| 803 196 / 152 | ||