Diagnostics | |

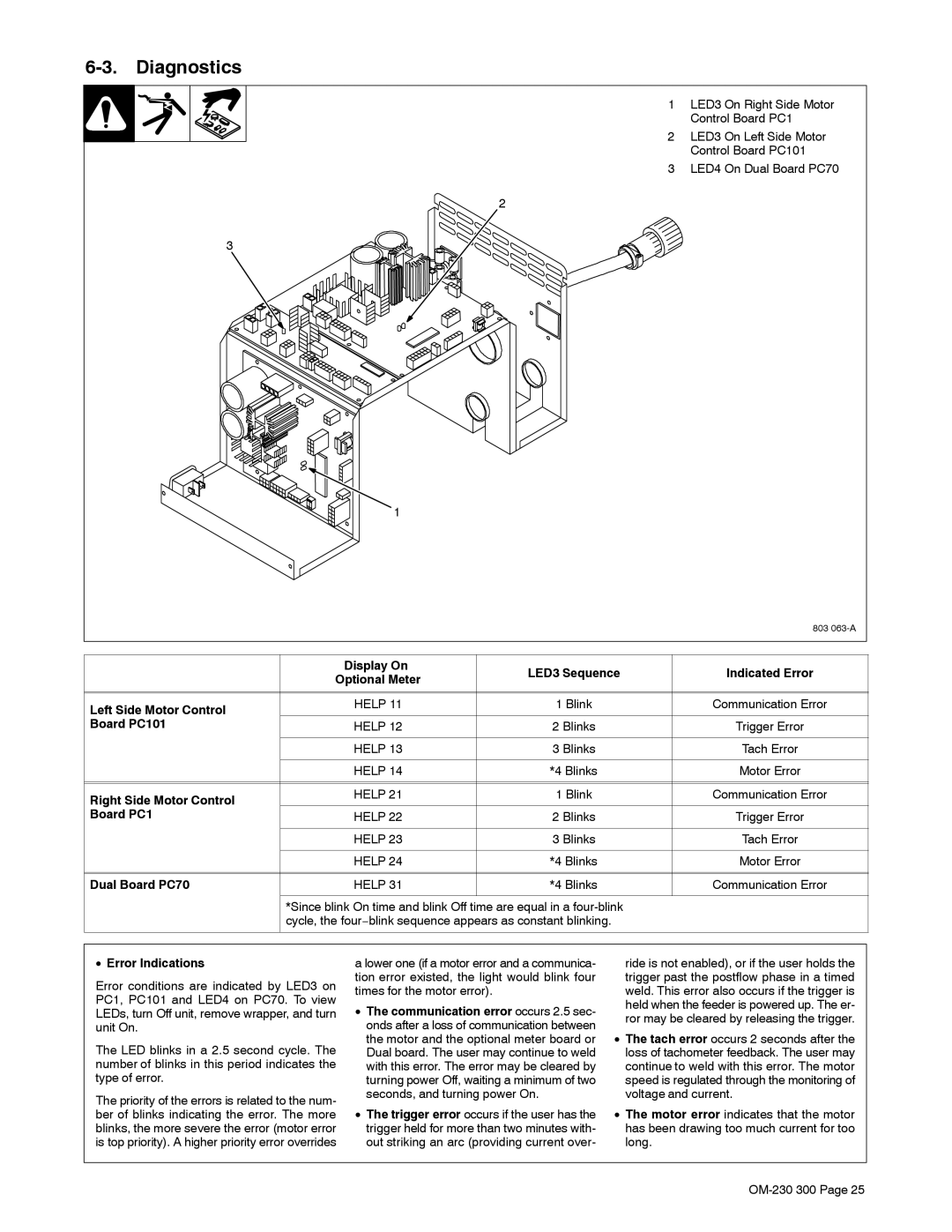

| 1 LED3 On Right Side Motor |

| Control Board PC1 |

| 2 LED3 On Left Side Motor |

| Control Board PC101 |

| 3 LED4 On Dual Board PC70 |

| 2 |

| 3 |

| 1 |

| 803 |

|

| Display On |

| LED3 Sequence |

| Indicated Error | ||

| Optional Meter |

|

| |||||

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

Left Side Motor Control |

| HELP 11 |

| 1 Blink |

|

| Communication Error | |

|

|

|

|

|

|

| ||

Board PC101 |

| HELP 12 |

| 2 Blinks |

|

| Trigger Error | |

|

|

|

|

|

|

|

| |

|

| HELP 13 |

| 3 Blinks |

|

| Tach Error | |

|

|

|

|

|

|

|

| |

|

| HELP 14 |

| *4 Blinks |

|

| Motor Error | |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

Right Side Motor Control |

| HELP 21 |

| 1 Blink |

|

| Communication Error | |

|

|

|

|

|

|

| ||

Board PC1 |

| HELP 22 |

| 2 Blinks |

|

| Trigger Error | |

|

|

|

|

|

|

|

| |

|

| HELP 23 |

| 3 Blinks |

|

| Tach Error | |

|

|

|

|

|

|

|

| |

|

| HELP 24 |

| *4 Blinks |

|

| Motor Error | |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

Dual Board PC70 |

| HELP 31 |

| *4 Blinks |

|

| Communication Error | |

|

|

|

|

| ||||

| *Since blink On time and blink Off time are equal in a |

|

| |||||

| cycle, the four−blink sequence appears as constant blinking. |

|

|

| ||||

|

|

|

|

|

|

| ||

|

|

|

| |||||

• Error Indications | a lower one (if a motor error and a communica- |

| ride is not enabled), or if the user holds the | |||||

Error conditions are indicated by LED3 on | tion error existed, the light would blink four |

| trigger past the postflow phase in a timed | |||||

times for the motor error). |

|

| weld. This error also occurs if the trigger is | |||||

PC1, PC101 and LED4 on PC70. To view |

|

| ||||||

• The communication error occurs 2.5 sec- |

| held when the feeder is powered up. The er- | ||||||

LEDs, turn Off unit, remove wrapper, and turn |

| |||||||

| ror may be cleared by releasing the trigger. | |||||||

unit On. | onds after a loss of communication between |

| ||||||

• The tach error occurs 2 seconds after the | ||||||||

The LED blinks in a 2.5 second cycle. The | the motor and the optional meter board or | |||||||

Dual board. The user may continue to weld |

| loss of tachometer feedback. The user may | ||||||

number of blinks in this period indicates the | with this error. The error may be cleared by |

| continue to weld with this error. The motor | |||||

type of error. | turning power Off, waiting a minimum of two |

| speed is regulated through the monitoring of | |||||

The priority of the errors is related to the num- | seconds, and turning power On. |

| voltage and current. | |||||

• The trigger error occurs if the user has the | • The motor error indicates that the motor | |||||||

ber of blinks indicating the error. The more | ||||||||

blinks, the more severe the error (motor error | trigger held for more than two minutes with- |

| has been drawing too much current for too | |||||

is top priority). A higher priority error overrides | out striking an arc (providing current over- |

| long. | |||||

|

|

|

|

|

|

|

| |