| I N V I S | I O N 4 5 6 M P |

|

| |||||

| C O P Y R | I G H T | (C) 1 9 9 8 |

|

| ||||

| M I | L | L E R E l | e c t r i c |

|

| |||

| M f | g | C o X X X X X X |

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

|

| |

|

|

|

|

|

|

|

|

|

|

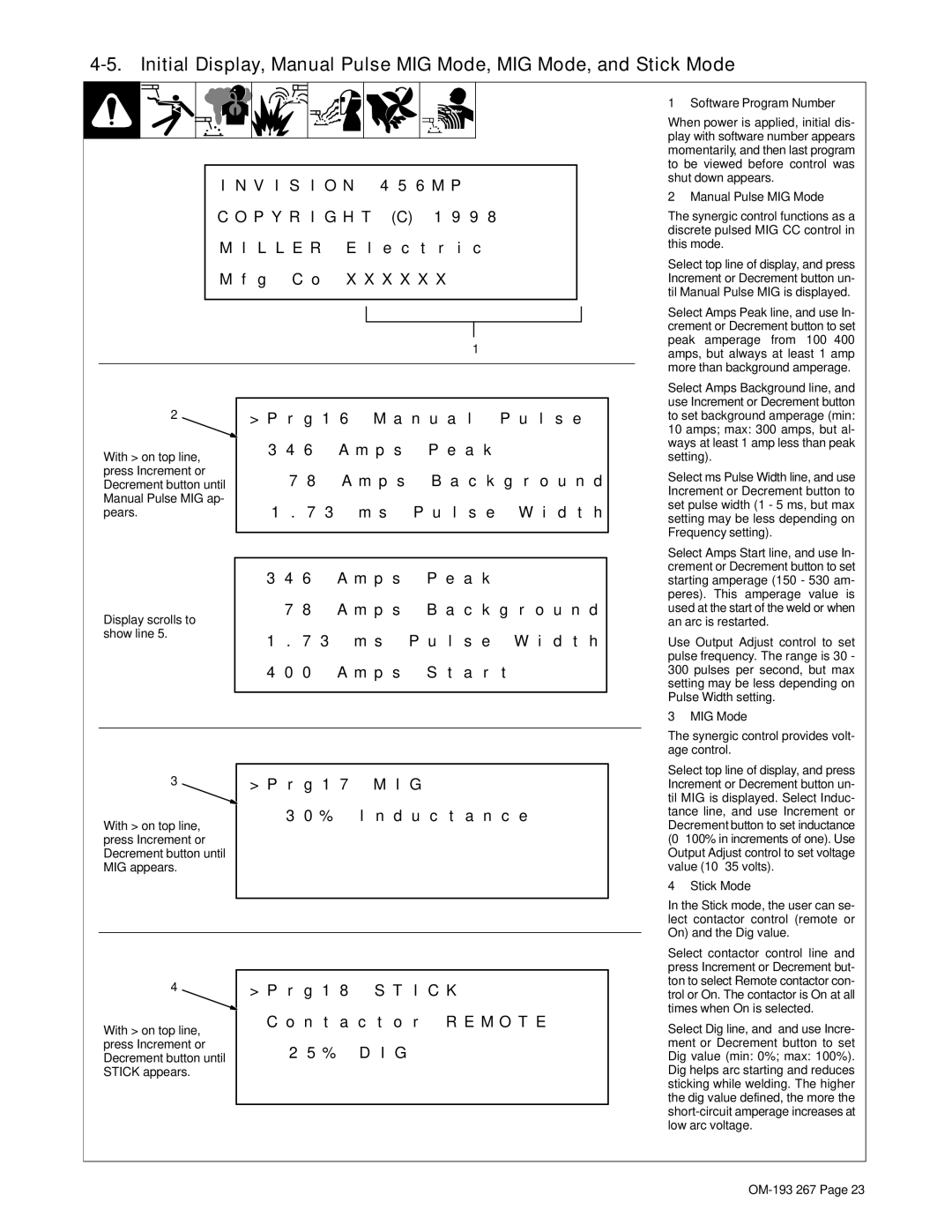

1 Software Program Number

When power is applied, initial dis- play with software number appears momentarily, and then last program to be viewed before control was shut down appears.

2 Manual Pulse MIG Mode

The synergic control functions as a discrete pulsed MIG CC control in this mode.

Select top line of display, and press Increment or Decrement button un- til Manual Pulse MIG is displayed.

Select Amps Peak line, and use In- crement or Decrement button to set peak amperage from 100−400 amps, but always at least 1 amp more than background amperage.

2

With > on top line, press Increment or Decrement button until Manual Pulse MIG ap- pears.

Display scrolls to show line 5.

| > P r | g 1 6 M a n u a l P u l s e | |||

| 3 4 6 A m p s P e a k | ||||

| 7 8 A m p s | B a c k g r o u n d | |||

| 1 . 7 3 | m s | P u l s e W i d t h | ||

|

|

|

| ||

|

|

|

| ||

| 3 4 6 |

| A m p s P e a k | ||

| 7 8 |

| A m p s | B a c k g r o u n d | |

| 1 . | 7 | 3 | m s | P u l s e W i d t h |

| 4 0 | 0 |

| A m p s | S t a r t |

|

|

|

|

|

|

Select Amps Background line, and use Increment or Decrement button to set background amperage (min: 10 amps; max: 300 amps, but al- ways at least 1 amp less than peak setting).

Select ms Pulse Width line, and use Increment or Decrement button to set pulse width (1 - 5 ms, but max setting may be less depending on Frequency setting).

Select Amps Start line, and use In- crement or Decrement button to set starting amperage (150 - 530 am- peres). This amperage value is used at the start of the weld or when an arc is restarted.

Use Output Adjust control to set pulse frequency. The range is 30 - 300 pulses per second, but max setting may be less depending on Pulse Width setting.

3 MIG Mode

The synergic control provides volt- age control.

3 | > P r | g 1 7 | M I G |

|

With > on top line, | 3 | 0 % | I n d u c t a n c e |

|

|

|

|

| |

press Increment or |

|

|

|

|

Decrement button until |

|

|

|

|

MIG appears. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 | > P r g 1 8 S T I C K |

With > on top line, | C o n t a c t o r R E M O T E |

| |

press Increment or | 2 5 % D I G |

Decrement button until | |

STICK appears. |

|

|

|

Select top line of display, and press Increment or Decrement button un- til MIG is displayed. Select Induc- tance line, and use Increment or Decrement button to set inductance (0−100% in increments of one). Use Output Adjust control to set voltage value (10−35 volts).

4 Stick Mode

In the Stick mode, the user can se- lect contactor control (remote or On) and the Dig value.

Select contactor control line and press Increment or Decrement but- ton to select Remote contactor con- trol or On. The contactor is On at all times when On is selected.

Select Dig line, and and use Incre- ment or Decrement button to set Dig value (min: 0%; max: 100%). Dig helps arc starting and reduces sticking while welding. The higher the dig value defined, the more the