|

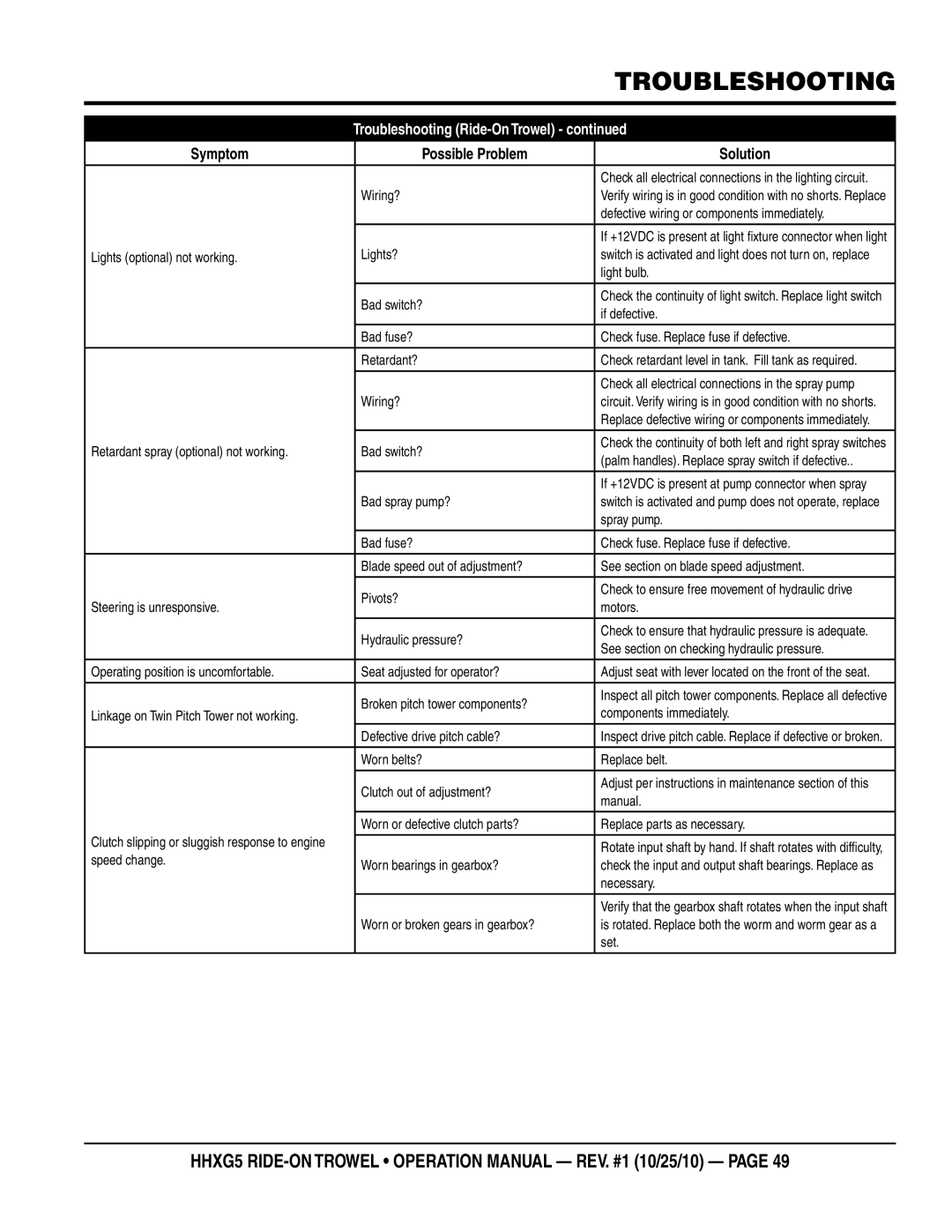

| TROUBLESHOOTING | |

|

|

| |

|

|

| |

| Troubleshooting | ||

Symptom | possible problem | Solution | |

|

|

| |

|

| Check all electrical connections in the lighting circuit. | |

| Wiring? | Verify wiring is in good condition with no shorts. Replace | |

|

| defective wiring or components immediately. | |

|

|

| |

|

| If +12VDC is present at light fi xture connector when light | |

Lights (optional) not working. | Lights? | switch is activated and light does not turn on, replace | |

|

| light bulb. | |

| Bad switch? | Check the continuity of light switch. Replace light switch | |

| if defective. | ||

|

| ||

| Bad fuse? | Check fuse. Replace fuse if defective. | |

|

|

| |

| Retardant? | Check retardant level in tank. Fill tank as required. | |

|

|

| |

|

| Check all electrical connections in the spray pump | |

| Wiring? | circuit. Verify wiring is in good condition with no shorts. | |

|

| Replace defective wiring or components immediately. | |

|

|

| |

Retardant spray (optional) not working. | Bad switch? | Check the continuity of both left and right spray switches | |

(palm handles). Replace spray switch if defective.. | |||

|

| ||

|

|

| |

|

| If +12VDC is present at pump connector when spray | |

| Bad spray pump? | switch is activated and pump does not operate, replace | |

|

| spray pump. | |

|

|

| |

| Bad fuse? | Check fuse. Replace fuse if defective. | |

|

|

| |

| Blade speed out of adjustment? | See section on blade speed adjustment. | |

|

|

| |

| Pivots? | Check to ensure free movement of hydraulic drive | |

Steering is unresponsive. | motors. | ||

| |||

|

|

| |

| Hydraulic pressure? | Check to ensure that hydraulic pressure is adequate. | |

| See section on checking hydraulic pressure. | ||

|

| ||

|

|

| |

Operating position is uncomfortable. | Seat adjusted for operator? | Adjust seat with lever located on the front of the seat. | |

| Broken pitch tower components? | Inspect all pitch tower components. Replace all defective | |

Linkage on Twin Pitch Tower not working. | components immediately. | ||

| |||

| Defective drive pitch cable? | Inspect drive pitch cable. Replace if defective or broken. | |

|

|

| |

| Worn belts? | Replace belt. | |

|

|

| |

| Clutch out of adjustment? | Adjust per instructions in maintenance section of this | |

| manual. | ||

|

| ||

|

|

| |

| Worn or defective clutch parts? | Replace parts as necessary. | |

Clutch slipping or sluggish response to engine |

|

| |

| Rotate input shaft by hand. If shaft rotates with diffi culty, | ||

speed change. |

| ||

Worn bearings in gearbox? | check the input and output shaft bearings. Replace as | ||

| |||

|

| necessary. | |

|

|

| |

|

| Verify that the gearbox shaft rotates when the input shaft | |

| Worn or broken gears in gearbox? | is rotated. Replace both the worm and worm gear as a | |

|

| set. | |

|

|

| |

HHXG5