BGD90PT, BGD90NT specifications

The Napoleon Fireplaces BGD90PT and BGD90NT represent the pinnacle of modern fireplace design, combining cutting-edge technology with timeless aesthetics. These models are specifically crafted for those who value both warmth and style in their living spaces.One of the standout features of the BGD90PT and BGD90NT is their large viewing area, which allows an unobstructed view of the flames, creating a mesmerizing focal point in any room. The expansive glass front enhances the ambiance of the fire, making it feel more immersive and inviting. This sleek design not only provides aesthetic benefits but also improves heat distribution, contributing to the overall efficiency of the fireplace.

The BGD90PT (Propane) and BGD90NT (Natural Gas) models utilize a range of advanced technologies to enhance performance. The patented PHAZER® technology creates a beautiful and realistic flame effect, while the variable speed blower and adjustable heat output allow for customized comfort levels. This precise control ensures that users can maintain the perfect temperature, regardless of outside conditions.

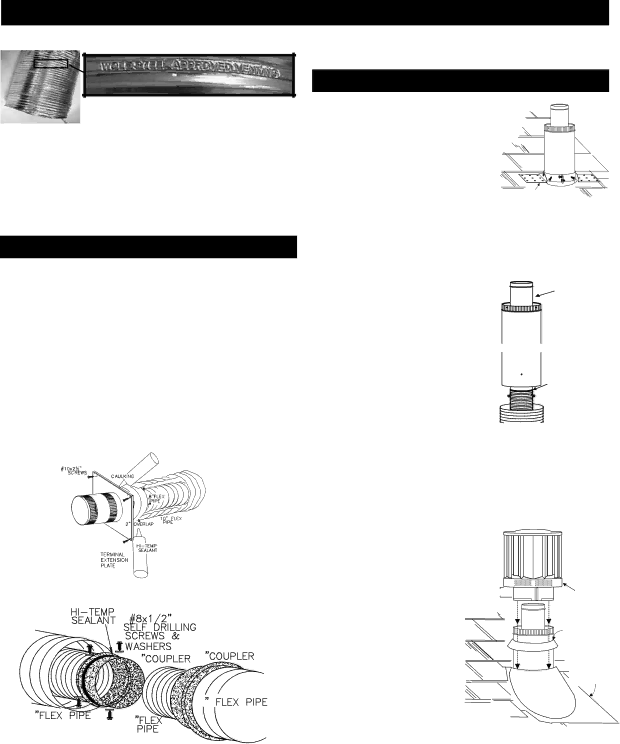

Furthermore, these models are engineered with Napoleon's exclusive TOP-VENT technology, which provides flexible venting options for easy installation. This feature allows homeowners to maximize their living space and choose the venting configuration that best suits their home’s layout.

The BGD90PT and BGD90NT also prioritize safety and efficiency. Both models are equipped with an electronic ignition system that provides reliable start-up, eliminating the hassle of traditional pilot lights. Additionally, the fireplaces include a built-in safety barrier to prevent accidental contact with the glass, making them suitable for homes with children and pets.

With their impressive heat output, the BGD90PT and BGD90NT can efficiently warm larger spaces, contributing to the overall comfort of your home. Their Energy Star rating ensures that they meet the highest standards for energy efficiency, making them an eco-friendly choice.

In terms of design, both models feature a contemporary look that complements various interior styles. From rustic to modern aesthetics, the BGD90PT and BGD90NT can enhance any home décor while providing the warmth and ambiance of a traditional fireplace.

In conclusion, the Napoleon Fireplaces BGD90PT and BGD90NT are an exceptional fusion of design, technology, and efficiency. Their impressive features make them an ideal choice for anyone looking to add a touch of elegance and functionality to their space, all while enjoying the comforting warmth of a beautiful fire.