USER MANUAL

ENGLISH

CLOSED POCKET FILTER CLEANING AND INTEGRITY CHECK

NOTE

The polyester closed pocket filters are normally kept clean by using the filter shaker supplied with the machine.

If necessary, they can be cleaned externally according to the following procedure.

When the filtering surfaces are worn, the filter must be replaced.

1.Drive the machine on a level ground and engage the parking brake with the pedal (75) and the lever (68).

2.Turn the ignition key (67) to “0”.

3.Open the hood (22) and fasten it with the support rod (36).

4.Disconnect the vacuum system motor connector (30).

5.Release the fasteners (A, Fig. 12) and remove the vacuum system cover (B).

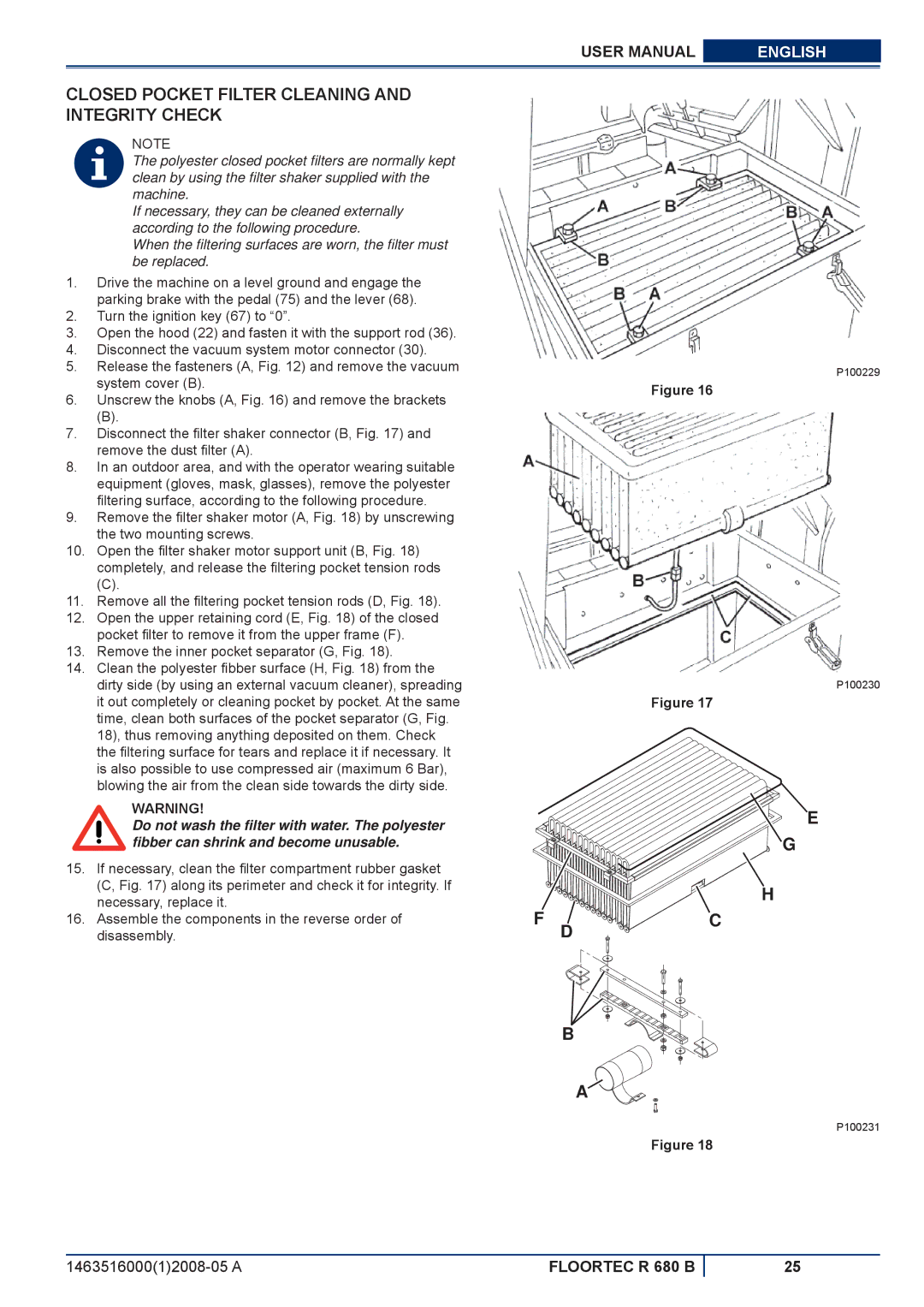

6.Unscrew the knobs (A, Fig. 16) and remove the brackets

(B).

7.Disconnect the filter shaker connector (B, Fig. 17) and remove the dust filter (A).

8.In an outdoor area, and with the operator wearing suitable equipment (gloves, mask, glasses), remove the polyester filtering surface, according to the following procedure.

9.Remove the filter shaker motor (A, Fig. 18) by unscrewing the two mounting screws.

10.Open the filter shaker motor support unit (B, Fig. 18) completely, and release the filtering pocket tension rods

(C).

11.Remove all the filtering pocket tension rods (D, Fig. 18).

12.Open the upper retaining cord (E, Fig. 18) of the closed pocket filter to remove it from the upper frame (F).

13.Remove the inner pocket separator (G, Fig. 18).

14.Clean the polyester fibber surface (H, Fig. 18) from the dirty side (by using an external vacuum cleaner), spreading it out completely or cleaning pocket by pocket. At the same time, clean both surfaces of the pocket separator (G, Fig. 18), thus removing anything deposited on them. Check the filtering surface for tears and replace it if necessary. It is also possible to use compressed air (maximum 6 Bar), blowing the air from the clean side towards the dirty side.

WARNING!

Do not wash the filter with water. The polyester fibber can shrink and become unusable.

15.If necessary, clean the filter compartment rubber gasket (C, Fig. 17) along its perimeter and check it for integrity. If necessary, replace it.

16.Assemble the components in the reverse order of disassembly.

Figure 16

Figure 17

F D ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() C

C

B![]()

![]()

A![]()

![]()

![]()

![]()

![]()

Figure 18

P100229

P100230

E

G

H

P100231

FLOORTEC R 680 B |

25