Conformiteitsverklaring

Konformitätserklärung

Déclaration de conformité

Conformity certificate

3301481112005-07A

14 13 12 11 3 10 9

19 2 17 15 16 4 5

18 8 7 20

BETRIEBSANLEITUNG

VORBEDINGUNG

EINLEITUNG

ALLGEMEINE ANWEISUNGEN

BETRIEBSANLEITUNG

Gefahrenbereiche

TERMINOLOGIEN UND IHRE BEDEUTUNG

VERANTWORTLICHKEIT DES BEDIENERS

SICHERHEITSVORSCHRIFTEN

Siehe Abb. C

TRANSPORT, VERLAGERUNG, INSTALLATION

WARNZEICHEN

ABLANDEN UND VERLAGERN

ALLGEMEINE PRÜFUNGEN

INSTALLATION

TECHNISCHE EIGENSCHAFTEN

VERPACKUNG

Beschreibung der Maschine mit Dach Siehe Abb. H

MASCHINENBESCHREIBUNG

SR 1450 B Siehe Abb. F

Beschreibung der Maschine ohne Dach Siehe Abb. G

Hydraulische Anlage

SICHERHEITSSYSTEME

TECHNISCHE DATEN

Instrumentenbrett

Betrieb

UMGEBUNGSWERTE

GERÄUSCHPEGEL

SR 1450 B

SR 1450 B Siehe Abb. J

ANWENDUNG

STEUERUNGEN UND INSTRUMENTE

SR 1450 D Siehe Abb. l

Ausschalten SR 1450 D

GEBRAUCHSANWEISUNGEN

GEBRAUCH DER MASCHINE

Anlassen SR 1450 D

MASCHINENABSTELLEN

Kehrgutsammeln SR 1450 B

BETRIEBSANLEITUNG

STÖRUNGEN UND ABHILFEN

STÖRUNGEN UND ABHILFEN

BETRIEBSANLEITUNG

3301481112005-07A

BETRIEBSANLEITUNG

Übermäßige Erwärmung des Motors SR 1450 B

BETRIEBSANLEITUNG

3301481112005-07A

PLANMÄSSIGE WARTUNG

REINIGUNG UND WARTUNG

WARTUNGSTABELLE

REINIGUNG

Gleichstrom-FahrmotorSR 1450 B

BETRIEBSANLEITUNG

3301481112005-07A

Ölstand

PLANMÄSSIGE PRÜFUNGEN

Batterie SR 1450 D

Reifendruck

Ersetzung des Hydraulikölfilters der Zahnradpumpe

AUSSERORDENTLICHE WARTUNG

Einstellung der Feststellbremse

Ersetzung des Luftfilters SR 1450 D

Ladung

BETRIEBSBATTERIE

SR 1450 B Betriebsnormen

Anwendung

Abbau der Hydraulikanlagen

ABBAU, ENTSORGUNG

ABBAU

ENTSORGUNG

SR 1450 D Siehe Abb. AG

PLÄNE

POSITION DER SICHERUNGEN

SCHALTPLÄNE

SR 1450 D Siehe Abb. AJ

ZUBEHÖR UND SONDERAUSSTATTUNG

HYDRAULIKPLAN

DRITTER SEITENBESEN

TRANSPORT, MANUTENTION, INSTALLATION

MANUEL DUTILISATION

IDENTIFICATION DE LA MACHINE

INTRODUCTION

AVERTISSEMENTS GENERAUX

AVANT-PROPOS

Zones dangereuses

PRECAUTIONS POUR LA SECURITE DES OPERATEURS

TERMINOLOGIE ET SIGNIFICATION

RESPONSABILITE DE LOPERATEUR

Voir Fig. C

TRANSPORT, MANUTENTION, INSTALLATION

SIGNAUX DATTENTION

DECHARGEMENT ET MANUTENTION

UTILISATION PREVUE

CARACTERISTIQUES TECHNIQUES

EMBALLAGES

CONTROLES GENERAUX

Conteneur déchets

DESCRIPTION DE LA MACHINE

SR 1450 B Voir Fig. F

Châssis

Système hydraulique

SYSTEMES DE SECURITE

DONNEES TECHNIQUES PRINCIPALES

Tableau de bord

Stockage

VALEURS ENVIRONNEMENTALES

NIVEAU DE BRUIT

Travail

SR 1450 D Voir Fig.

COMMANDES ET INSTRUMENTS

Commandes par leviers

UTILISATION

Arrêt SR 1450 D

INSTRUCTIONS POUR LUTILISATION

UTILISATION DE LA MACHINE

Démarrage SR 1450 D

ARRET DE LA MACHINE

Ramassage des déchets SR 1450 B

MANUEL DUTILISATION

PROBLEMES ET REMEDES

PROBLEMES ET REMEDES

MANUEL DUTILISATION

Le fusible du secoueur grille

MANUEL DUTILISATION

CAUSE

Réchauffement excessif du moteur SR 1450 B

PROBLEME

MANUEL DUTILISATION

ENTRETIEN PERIODIQUE

NETTOYAGE ET ENTRETIEN

TABLEAU DENTRETIEN

NETTOYAGE

MANUEL DUTILISATION

Moteur à courant continu de traction SR 1450 B

Niveau du liquide de réfroidissement SR 1450 D

CONTROLES PERIODIQUES

Pression pneus

Niveaux de lhuile

Remplacement de la brosse centrale

Remplacement du filtre à air SR 1450 D

Remplacement des joints latéraux droits

Remplacement des joints latéraux gauches

Charge

BATTERIE DE SERVICE

SR 1450 B Normes de services

Utilisation

Démantèlement des circuits hydrauliques

DEMANTELEMENT, ECOULEMENT

DEMANTELEMENT

ECOULEMENT

SR 1450 D Voir Fig. AG

SCHEMAS

SCHEMAS ELECTRIQUES

POSITION FUSIBLES

SR 1450 D Voir fig. AJ

ACCESSOIRES ET OPTIONS

SCHEMA HYDRAULIQUE

TROISIEME BROSSE

USER MANUAL

MACHINE IDENTIFICATION

GENERAL WARNINGS

USER MANUAL

FOREWORD

Danger zones

OPERATORS SAFETY PRECAUTIONS

DEFINITIONS

OPERATORS RESPONSIBILITY

See Fig. C

TRANSPORTATION, HANDLING, INSTALLATION

WARNING SIGNS

DISCHARGE AND HANDLING

MACHINE LAYOUT

TECHNICAL DATA

PACKING

GENERAL CHECKS

Frame

MACHINE DESCRIPTION

SR 1450 B See Fig. F

Description of the machine with roof See Fig. H

Hydraulic system

SAFETY SYSTEMS

MAIN TECHNICAL DATA

Dashboard

Storage

ENVIRONMENTAL CONDITIONS

NOISE LEVEL

Working

Lever controls

CONTROLS AND INSTRUMENTS

SR 1450 D See Fig.

SR 1450 B See Fig. J

Stop SR 1450 D

INSTRUCTIONS FOR USE

MACHINE USE

Start SR 1450 D

MACHINE STOP

Waste collection SR 1450 B

USER MANUAL

PROBLEMS AND REMEDIES

PROBLEMS AND REMEDIES

Blown filter shaker fuse

REMEDY

SR 1450 B motor overheating SR 1450 B

PROBLEM

CAUSE

PERIODICAL MAINTENANCE

CLEANING AND MAINTENANCE

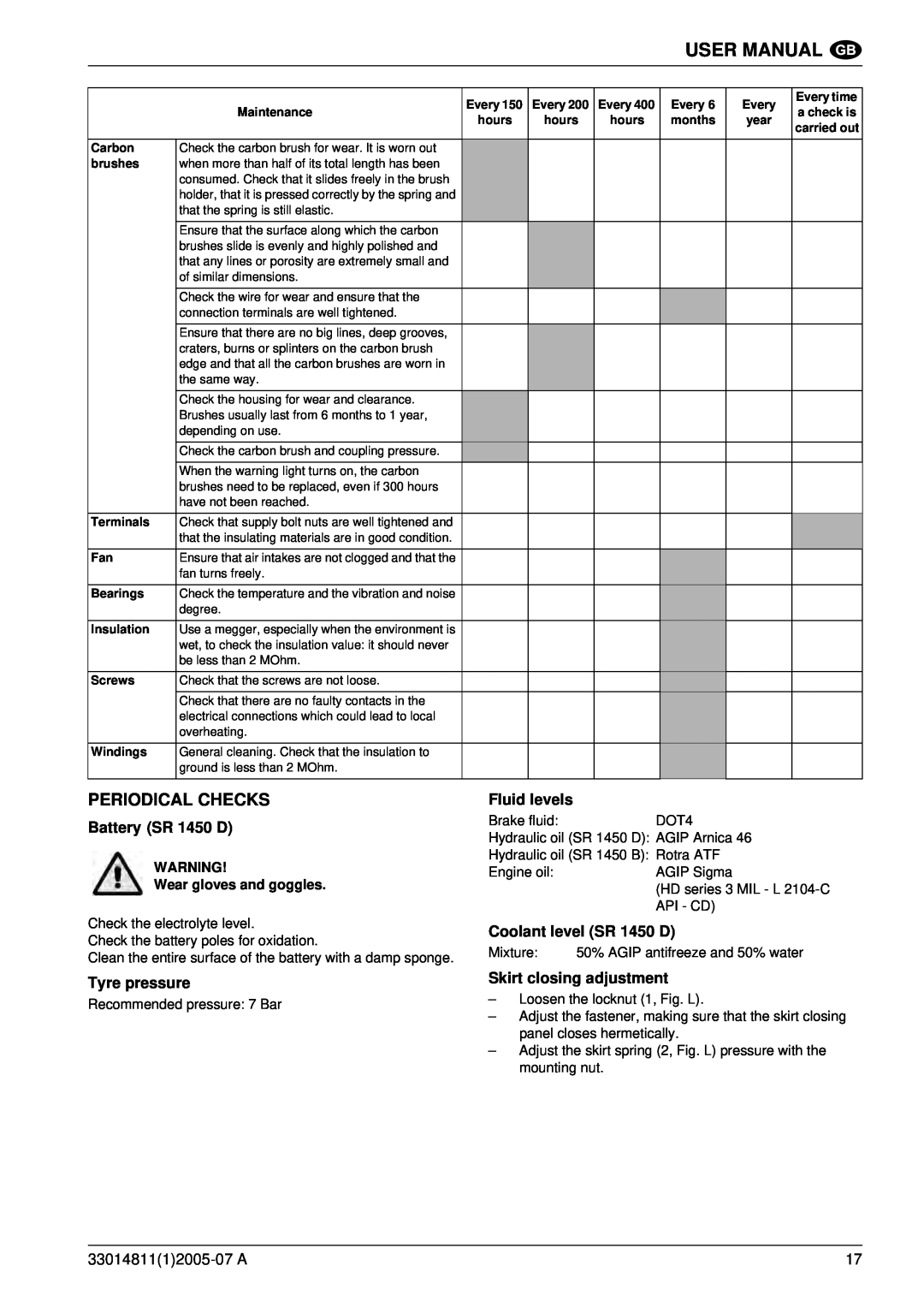

MAINTENANCE TABLE

CLEANING

USER MANUAL

Drive direct current motor SR 1450 B

Tyre pressure

Battery SR 1450 D

Skirt closing adjustment

PERIODICAL CHECKS

Gear pump hydraulic oil filter replacement

EXTRAORDINARY MAINTENANCE

Parking brake adjustment

Engine air cleaner replacement SR 1450 D

Overcharge

ACCESSORY BATTERY

SR 1450 B Service instructions

Maintenance

Hydraulic system dismantling

DISMANTLING, DISPOSAL

DISMANTLING

DISPOSAL

SR 1450 D See Fig. AG

DIAGRAMS

WIRING DIAGRAMS

FUSE POSITIONS

SR 1450 D See Fig. AJ

ACCESSORIES AND OPTIONS

HYDRAULIC DIAGRAM

THIRD BROOM

GEBRUIKERSHANDLEIDING

VOORWOORD

INLEIDING

ALGEMENE WAARSCHUWINGEN

GEBRUIKERSHANDLEIDING

Gevarenzones

DEFINITIES

VERANTWOORDELIJKHEID VAN DE BEDIENER

VEILIGHEIDSMAATREGELEN VOOR DE BEDIENER

Zie Afb. C

VERVOER, HANTERING, INSTALLATIE

WAARSCHUWINGSTEKENS

LOSSEN EN BEDIENING

ALGEMENE CONTROLES

INSTALLATIE

TECHNISCHE GEGEVENS

VERPAKKING

Beschrijving van de machine met dak Zie Afb. H

BESCHRIJVING VAN DE MACHINE

SR 1450 B Zie Afb. F

Beschrijving van de machine zonder dak Zie Afb. G

Elektrisch systeem

VEILIGHEIDSSYSTEMEN

BELANGRIJKSTE TECHNISCHE GEGEVENS

Hydraulisch systeem

Opslag

MILIEU

GELUIDSNIVEAU

Bedrijf

SR 1450 B Zie Afb. J

GEBRUIK

BEDIENINGEN EN INSTRUMENTEN

SR 1450 D Zie Afb

GEBRUIKERSHANDLEIDING

GEBRUIKSINSTRUCTIES

GEBRUIK VAN DE MACHINE

Afvalverzameling SR 1450 D

MACHINESTOP

Afvalverzameling SR 1450 B

GEBRUIKERSHANDLEIDING

PROBLEMEN EN OPLOSSINGEN

PROBLEMEN EN OPLOSSINGEN

GEBRUIKERSHANDLEIDING

Gesprongen zekering filterschudder

GEBRUIKERSHANDLEIDING

OORZAAK

SR 1450 B oververhitting motor SR 1450 B

GEBRUIKERSHANDLEIDING

PROBLEEM

PERIODIEK ONDERHOUD

REINIGING EN ONDERHOUD

ONDERHOUDSTABEL

REINIGING

GEBRUIKERSHANDLEIDING

Aandrijving gelijkstroommotor SR 1450 B

Vloeistofpeil

PERIODIEKE CONTROLES

Accu SR 1450 D

Bandenspanning

Vervanging keerring rechts

BUITENGEWOON ONDERHOUD

Afstelling handrem

Vervanging motorluchtfilter SR 1450 D

Opladen

EXTRA ACCU

SR 1450 B Onderhoudsinstructies

Gebruik

Het hydraulische systeem demonteren

DEMONTEREN, AFDANKEN

DEMONTEREN

AFDANKEN

SR 1450 D Zie Afb. AG

SCHEMA’S

BEDRADINGSSCHEMA’S

ZEKERINGENPOSITIES

SR 1450 D Zie Afb. AJ

ACCESSOIRES EN OPTIES

SCHEMA HYDRAULICA

DERDE BORSTEL

3301481112005-07A

2 19 15

3301481112005-07A

3301481112005-07A

3301481112005-07A

3301481112005-07A

3301481112005-07A

3301481112005-07A

AK AL

Page

1.300

18 13 12 11 10 9

2 16 14 15 4 17

2 1.470 4 6

1.300

13 2 2.230 4 6

12 1

8 11 9 7 10