TROUBLESHOOTING AND MAINTENANCE

Make sure all parts are properly tightened each time the weight rack is used. Replace any worn parts immediately. The weight rack can be cleaned using a damp cloth and mild

TIGHTENING THE CABLES

Woven cable, the type of cable used on the weight rack, can stretch slightly when it is first used. If there is slack in the cables before resistance is felt, the cables should be tightened. Make sure that the cables are not too tight, or the weight carriage will be lifted. Slack can be removed in the following ways.

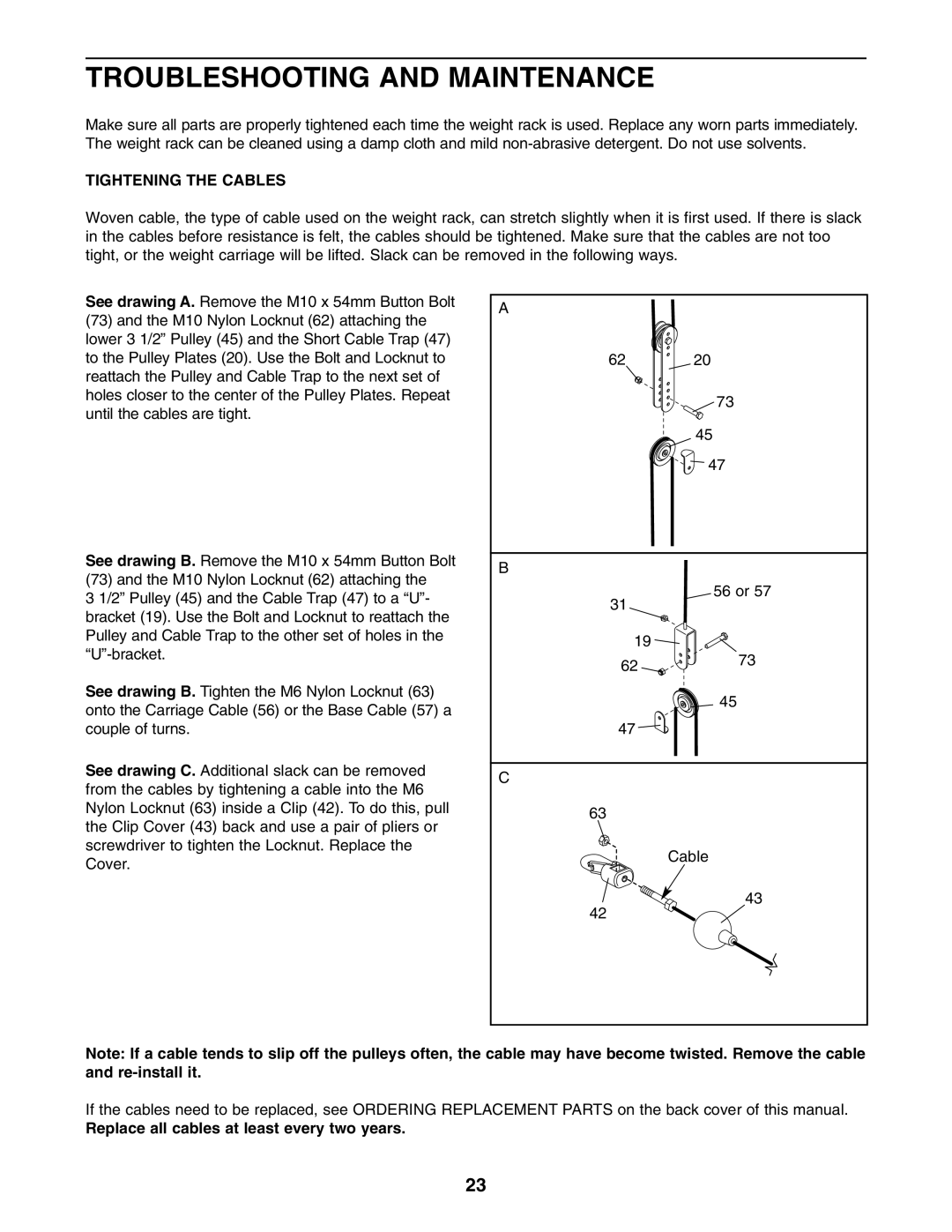

See drawing A. Remove the M10 x 54mm Button Bolt

(73)and the M10 Nylon Locknut (62) attaching the lower 3 1/2” Pulley (45) and the Short Cable Trap (47) to the Pulley Plates (20). Use the Bolt and Locknut to reattach the Pulley and Cable Trap to the next set of holes closer to the center of the Pulley Plates. Repeat until the cables are tight.

See drawing B. Remove the M10 x 54mm Button Bolt

(73)and the M10 Nylon Locknut (62) attaching the 3 1/2” Pulley (45) and the Cable Trap (47) to a “U”- bracket (19). Use the Bolt and Locknut to reattach the Pulley and Cable Trap to the other set of holes in the

See drawing B. Tighten the M6 Nylon Locknut (63) onto the Carriage Cable (56) or the Base Cable (57) a couple of turns.

See drawing C. Additional slack can be removed from the cables by tightening a cable into the M6 Nylon Locknut (63) inside a Clip (42). To do this, pull the Clip Cover (43) back and use a pair of pliers or screwdriver to tighten the Locknut. Replace the Cover.

A |

|

62 | 20 |

| 73 |

| 45 |

| 47 |

B |

|

31 | 56 or 57 |

| |

19 |

|

62 | 73 |

| |

| 45 |

47 |

|

C |

|

63 |

|

| Cable |

42 | 43 |

|

Note: If a cable tends to slip off the pulleys often, the cable may have become twisted. Remove the cable and

If the cables need to be replaced, see ORDERING REPLACEMENT PARTS on the back cover of this manual.

Replace all cables at least every two years.

23