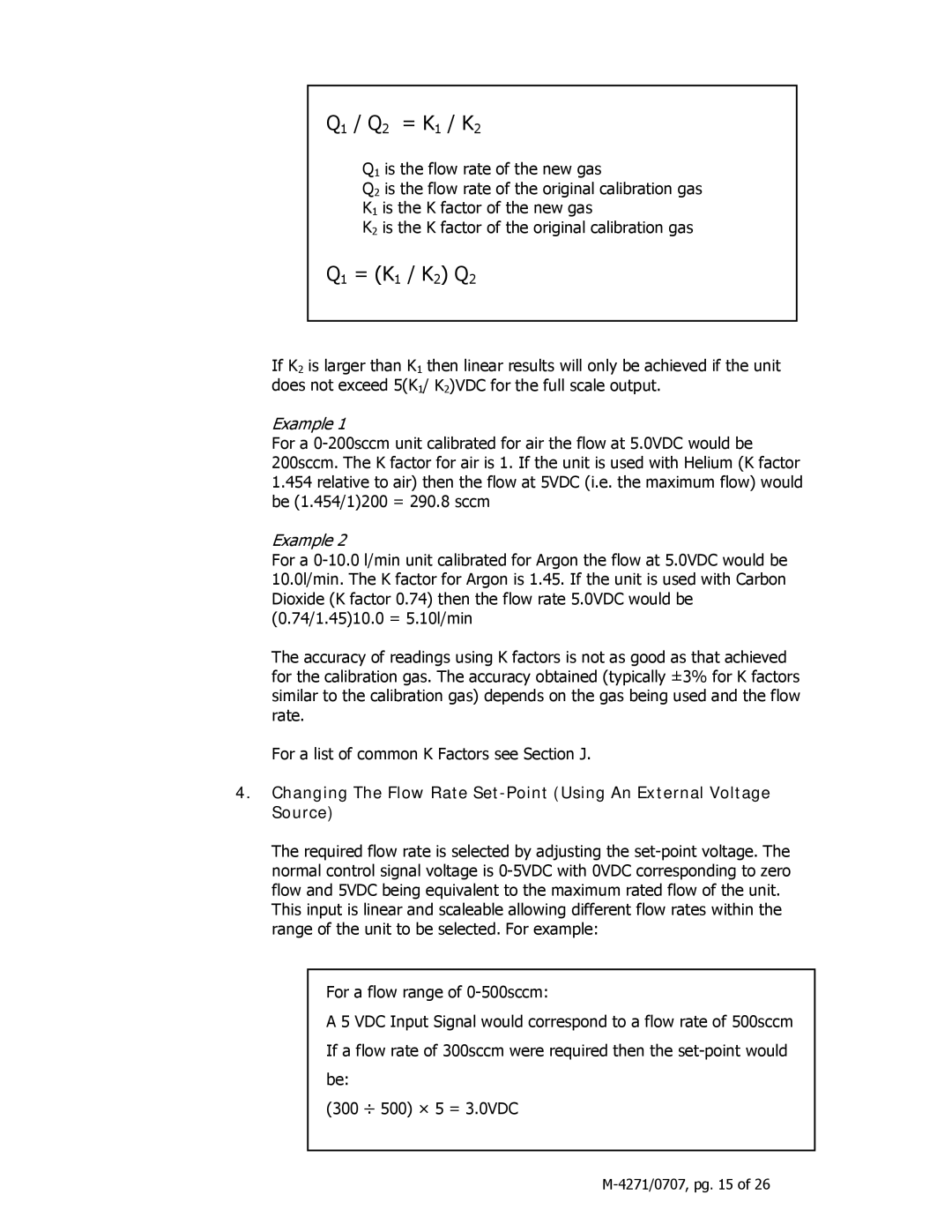

Q1 / Q2 = K1 / K2

Q1 is the flow rate of the new gas

Q2 is the flow rate of the original calibration gas

K1 is the K factor of the new gas

K2 is the K factor of the original calibration gas

Q1 = (K1 / K2) Q2

If K2 is larger than K1 then linear results will only be achieved if the unit does not exceed 5(K1/ K2)VDC for the full scale output.

Example 1

For a

Example 2

For a

The accuracy of readings using K factors is not as good as that achieved for the calibration gas. The accuracy obtained (typically ±3% for K factors similar to the calibration gas) depends on the gas being used and the flow rate.

For a list of common K Factors see Section J.

4.Changing The Flow Rate

The required flow rate is selected by adjusting the

This input is linear and scaleable allowing different flow rates within the range of the unit to be selected. For example:

For a flow range of

A 5 VDC Input Signal would correspond to a flow rate of 500sccm If a flow rate of 300sccm were required then the

(300 ÷ 500) × 5 = 3.0VDC