sensor design. This proven design minimizes zero drift while maintaining fast response and linear outputs with virtually no maintenance.

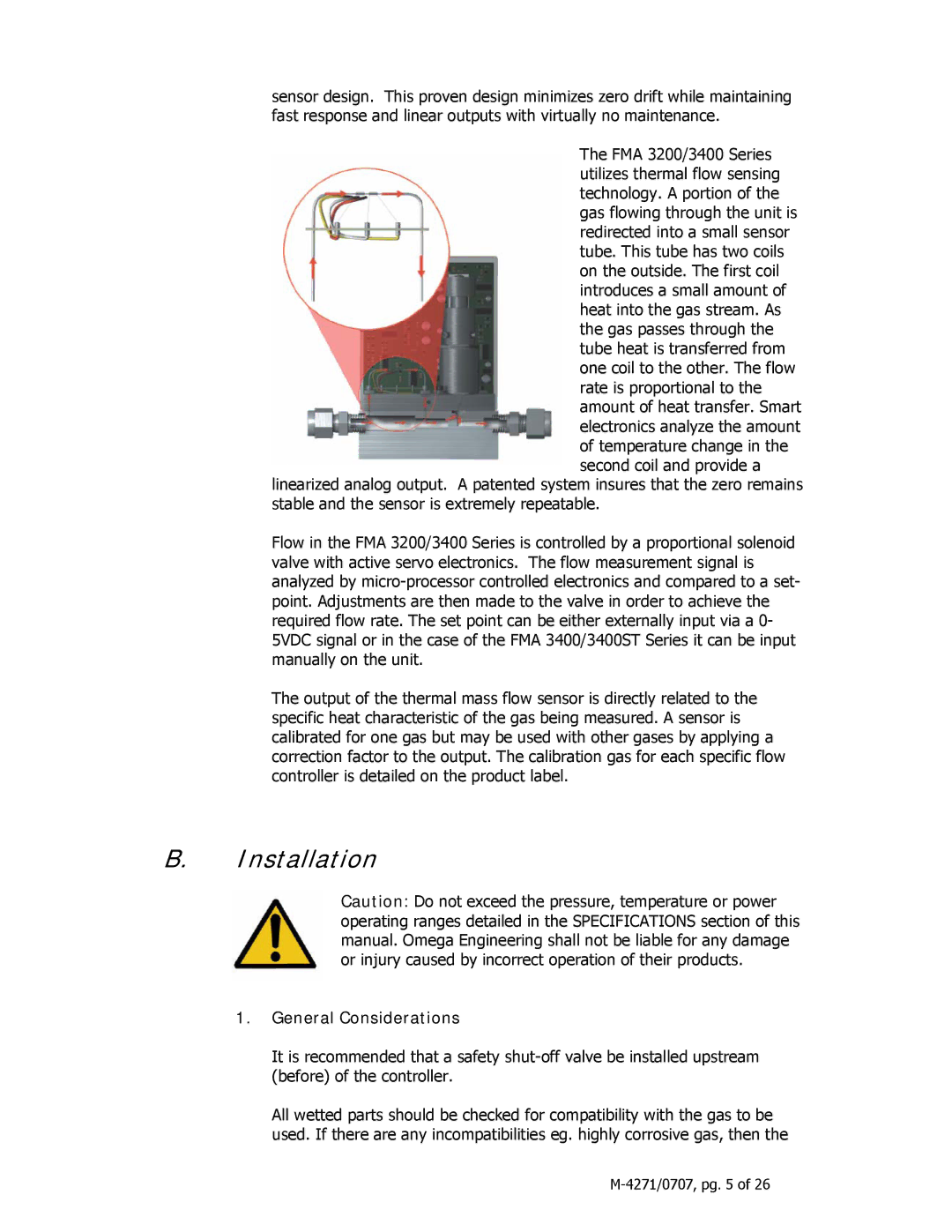

The FMA 3200/3400 Series utilizes thermal flow sensing technology. A portion of the gas flowing through the unit is redirected into a small sensor tube. This tube has two coils on the outside. The first coil introduces a small amount of heat into the gas stream. As the gas passes through the tube heat is transferred from one coil to the other. The flow rate is proportional to the amount of heat transfer. Smart electronics analyze the amount of temperature change in the second coil and provide a

linearized analog output. A patented system insures that the zero remains stable and the sensor is extremely repeatable.

Flow in the FMA 3200/3400 Series is controlled by a proportional solenoid valve with active servo electronics. The flow measurement signal is analyzed by

The output of the thermal mass flow sensor is directly related to the specific heat characteristic of the gas being measured. A sensor is calibrated for one gas but may be used with other gases by applying a correction factor to the output. The calibration gas for each specific flow controller is detailed on the product label.

B.Installation

Caution: Do not exceed the pressure, temperature or power operating ranges detailed in the SPECIFICATIONS section of this manual. Omega Engineering shall not be liable for any damage or injury caused by incorrect operation of their products.

1.General Considerations

It is recommended that a safety

All wetted parts should be checked for compatibility with the gas to be used. If there are any incompatibilities eg. highly corrosive gas, then the