Specifications 9

|

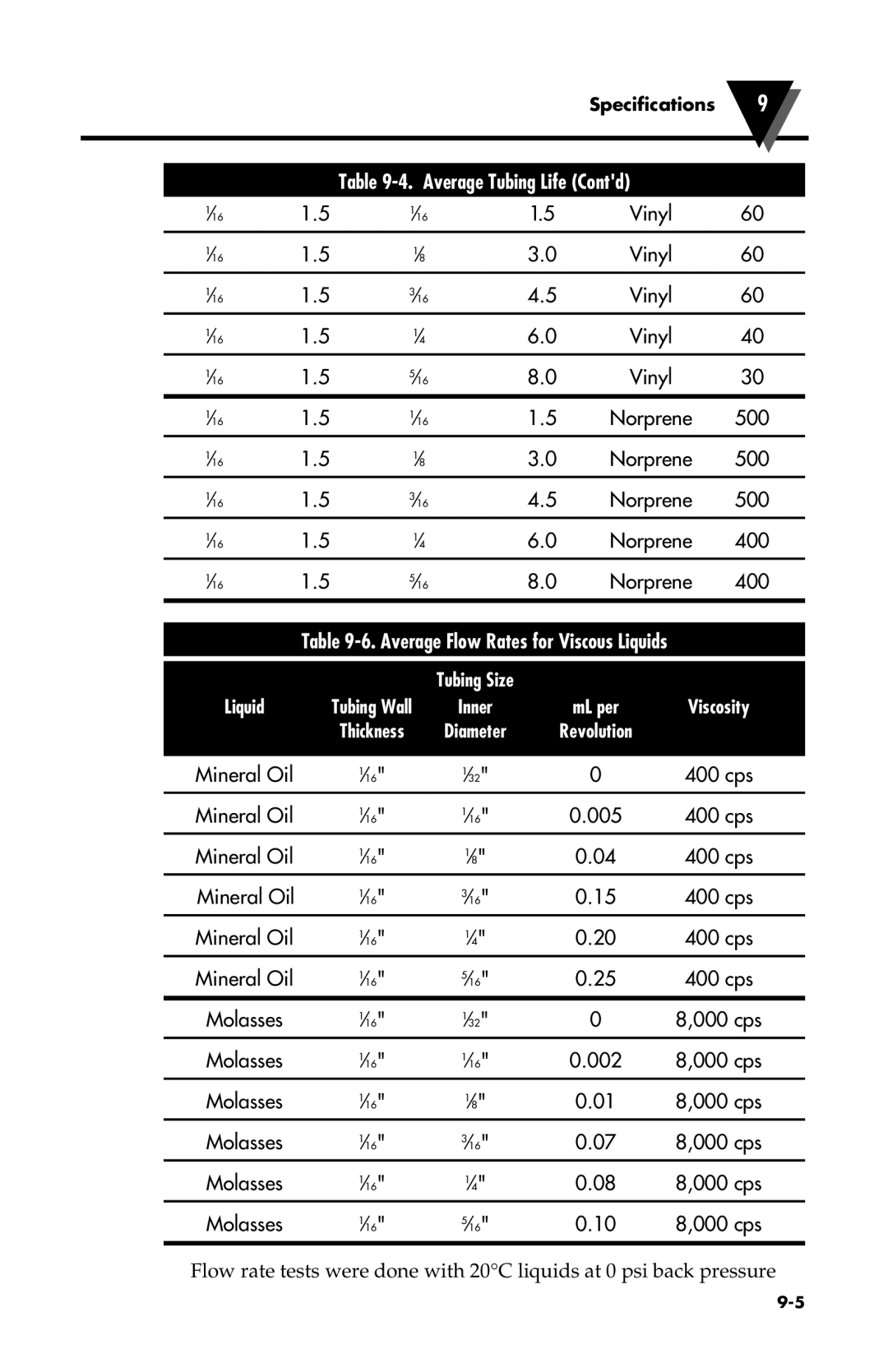

| Table |

| ||

1⁄16 | 1.5 | 1⁄16 | 1.5 | Vinyl | 60 |

1⁄16 | 1.5 | 1⁄8 | 3.0 | Vinyl | 60 |

1⁄16 | 1.5 | 3⁄16 | 4.5 | Vinyl | 60 |

1⁄16 | 1.5 | 1⁄4 | 6.0 | Vinyl | 40 |

1⁄16 | 1.5 | 5⁄16 | 8.0 | Vinyl | 30 |

1⁄16 | 1.5 | 1⁄16 | 1.5 | Norprene | 500 |

1⁄16 | 1.5 | 1⁄8 | 3.0 | Norprene | 500 |

1⁄16 | 1.5 | 3⁄16 | 4.5 | Norprene | 500 |

1⁄16 | 1.5 | 1⁄4 | 6.0 | Norprene | 400 |

1⁄16 | 1.5 | 5⁄16 | 8.0 | Norprene | 400 |

Table 9-6. Average Flow Rates for Viscous Liquids

|

| Tubing Size |

|

|

Liquid | Tubing Wall | Inner | mL per | Viscosity |

| Thickness | Diameter | Revolution |

|

|

|

|

|

|

Mineral Oil | 1⁄16" | 1⁄32" | 0 | 400 cps |

Mineral Oil | 1⁄16" | 1⁄16" | 0.005 | 400 cps |

Mineral Oil | 1⁄16" | 1⁄8" | 0.04 | 400 cps |

Mineral Oil | 1⁄16" | 3⁄16" | 0.15 | 400 cps |

Mineral Oil | 1⁄16" | 1⁄4" | 0.20 | 400 cps |

Mineral Oil | 1⁄16" | 5⁄16" | 0.25 | 400 cps |

Molasses | 1⁄16" | 1⁄32" | 0 | 8,000 cps |

Molasses | 1⁄16" | 1⁄16" | 0.002 | 8,000 cps |

Molasses | 1⁄16" | 1⁄8" | 0.01 | 8,000 cps |

Molasses | 1⁄16" | 3⁄16" | 0.07 | 8,000 cps |

Molasses | 1⁄16" | 1⁄4" | 0.08 | 8,000 cps |

Molasses | 1⁄16" | 5⁄16" | 0.10 | 8,000 cps |

Flow rate tests were done with 20°C liquids at 0 psi back pressure