6.3.Reassenbly instructions

6.3.1.Attention when

·Please execute writing BIOS ID when you exchange the main board.

·Parts (sheet and rubber) etc. related various the conductive cloth and heat spreader cannot be recycled. Use new parts.

6.3.2.Assembly knowhow of part LCD

![]() LCD rubber, LCD side rubber and LCD backing rubber’s putting

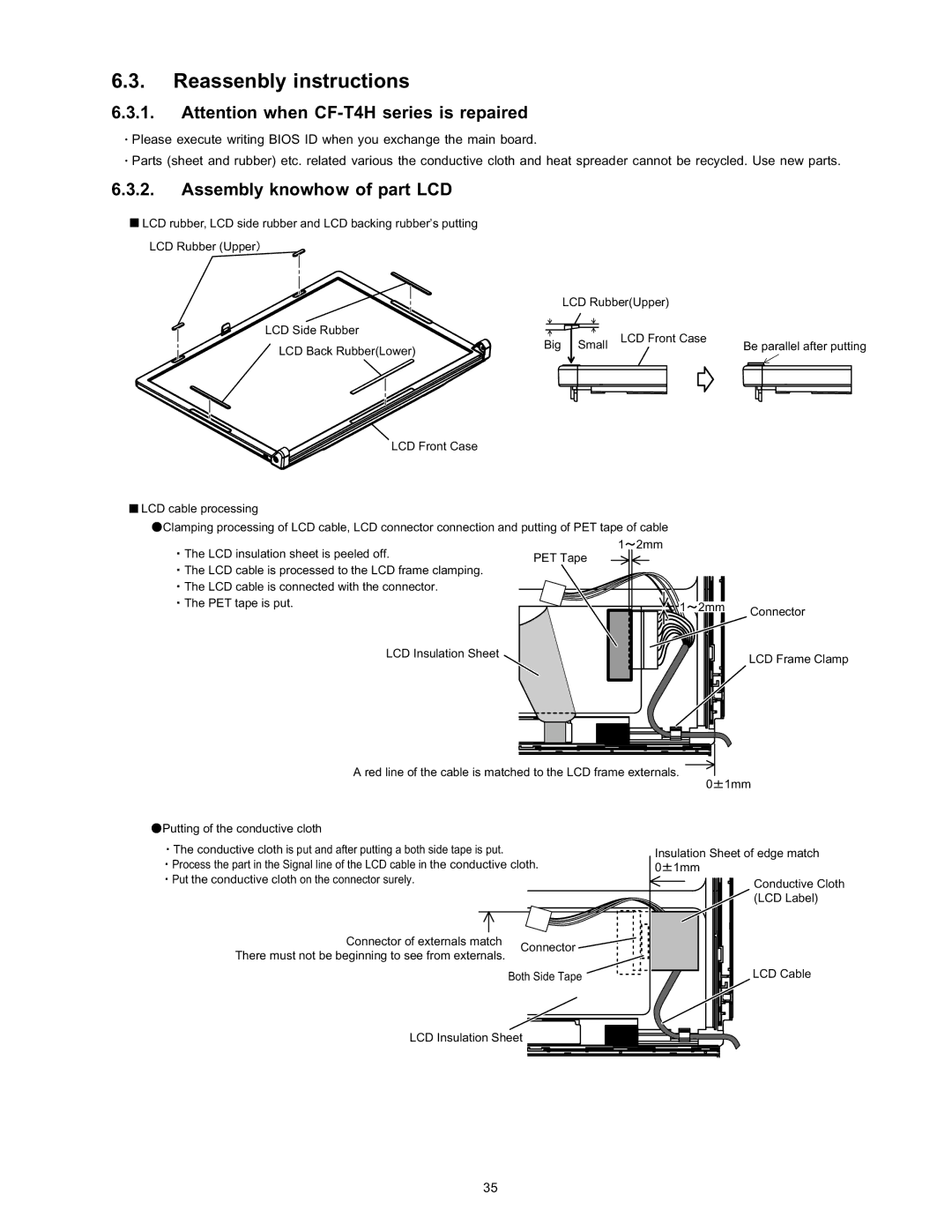

LCD rubber, LCD side rubber and LCD backing rubber’s putting

LCD Rubber (Upper![]()

| LCD Rubber(Upper) | |

LCD Side Rubber |

| LCD Front Case |

LCD Back Rubber(Lower) | Big Small | |

|

| |

LCD Front Case

![]() LCD cable processing

LCD cable processing

![]() Clamping processing of LCD cable, LCD connector connection and putting of PET tape of cable 1

Clamping processing of LCD cable, LCD connector connection and putting of PET tape of cable 1![]() 2mm

2mm

The LCD insulation sheet is peeled off. | PET Tape |

|

The LCD cable is processed to the LCD frame clamping. |

| |

|

| |

The LCD cable is connected with the connector. |

|

|

The PET tape is put. | 1 | 2mm |

| ||

LCD Insulation Sheet |

|

|

Be parallel after putting

Connector

LCD Frame Clamp

A red line of the cable is matched to the LCD frame externals.

0![]() 1mm

1mm

![]() Putting of the conductive cloth

Putting of the conductive cloth

The conductive cloth is put and after putting a both side tape is put.

Process the part in the Signal line of the LCD cable in the conductive cloth.

Put the conductive cloth on the connector surely.

Connector of externals match | Connector | |

There must not be beginning to see from externals. | ||

| ||

| Both Side Tape |

Insulation Sheet of edge match 0![]() 1mm

1mm

Conductive Cloth (LCD Label)

LCD Cable

LCD Insulation Sheet

35