PRECAUTIONS IN USING THE COUNTER

Cautions for circuits

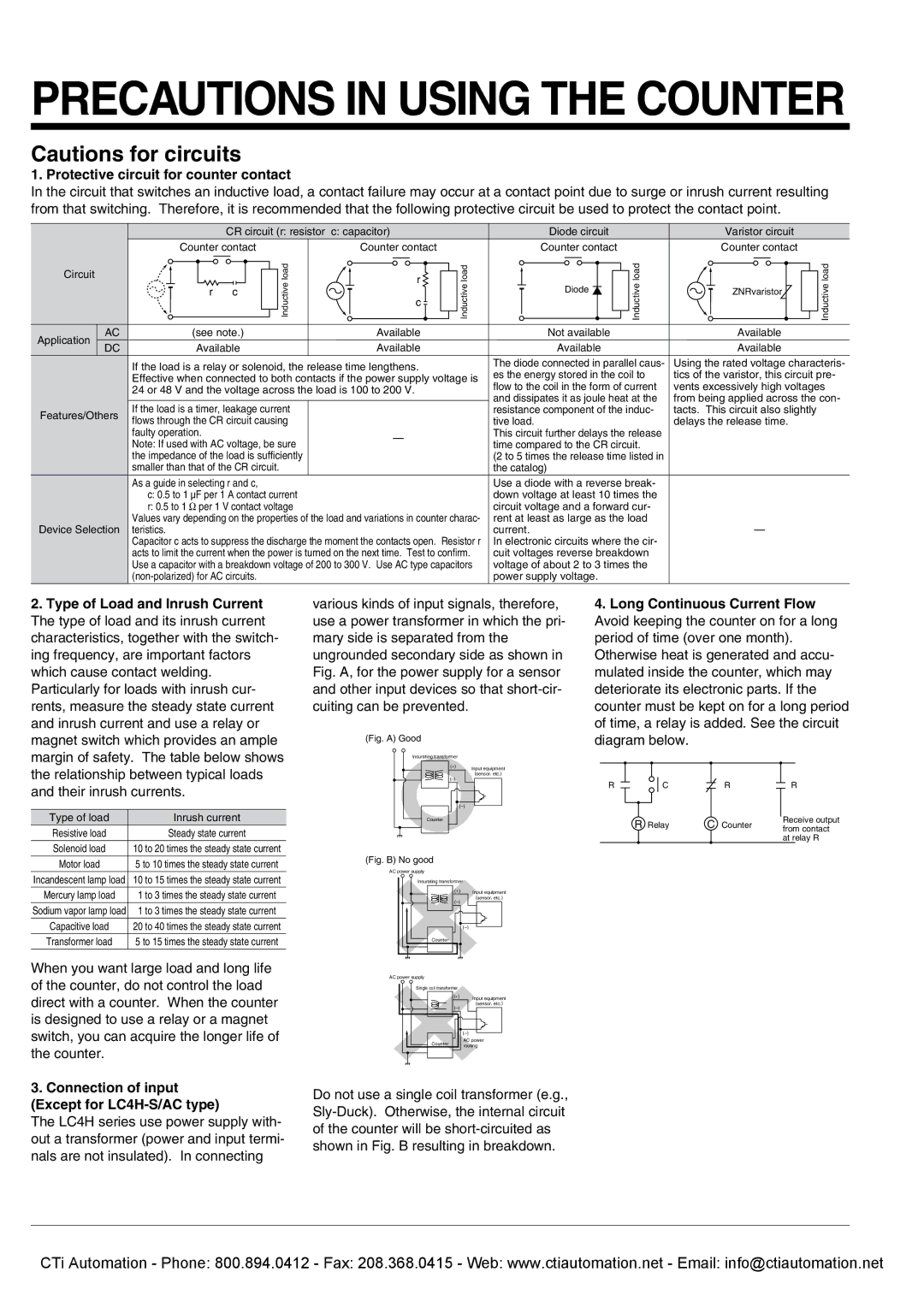

1. Protective circuit for counter contact

In the circuit that switches an inductive load, a contact failure may occur at a contact point due to surge or inrush current resulting from that switching. Therefore, it is recommended that the following protective circuit be used to protect the contact point.

|

| CR circuit (r: resistor | c: capacitor) |

| Diode circuit |

| Varistor circuit |

| |

| Counter contact |

| Counter contact |

| Counter contact |

| Counter contact |

| |

Circuit |

|

| load | r | load |

| load |

| load |

|

|

| Inductive | Inductive | Diode | Inductive |

| Inductive | |

| r | c | c | ZNRvaristor | |||||

|

|

|

|

| |||||

|

|

|

|

|

| ||||

AC | (see note.) |

| Available |

| Not available |

| Available |

| |

Application | Available |

| Available |

| Available |

| Available |

| |

DC |

|

|

|

| |||||

| If the load is a relay or solenoid, the release time lengthens. | The diode connected in parallel caus- | Using the rated voltage characteris- | |

| es the energy stored in the coil to | tics of the varistor, this circuit pre- | ||

| Effective when connected to both contacts if the power supply voltage is | |||

| flow to the coil in the form of current | vents excessively high voltages | ||

| 24 or 48 V and the voltage across the load is 100 to 200 V. | |||

| and dissipates it as joule heat at the | from being applied across the con- | ||

|

|

| ||

Features/Others | If the load is a timer, leakage current |

| resistance component of the induc- | tacts. This circuit also slightly |

flows through the CR circuit causing |

| tive load. | delays the release time. | |

|

| |||

| faulty operation. | — | This circuit further delays the release |

|

| Note: If used with AC voltage, be sure | time compared to the CR circuit. |

| |

|

|

| ||

| the impedance of the load is sufficiently |

| (2 to 5 times the release time listed in |

|

| smaller than that of the CR circuit. |

| the catalog) |

|

| As a guide in selecting r and c, |

| Use a diode with a reverse break- |

|

| c: 0.5 to 1 µF per 1 A contact current |

| down voltage at least 10 times the |

|

| r: 0.5 to 1 Ω per 1 V contact voltage |

| circuit voltage and a forward cur- |

|

| Values vary depending on the properties of the load and variations in counter charac- | rent at least as large as the load | — | |

Device Selection teristics. |

| current. | ||

| Capacitor c acts to suppress the discharge the moment the contacts open. Resistor r | In electronic circuits where the cir- |

| |

| acts to limit the current when the power is turned on the next time. Test to confirm. | cuit voltages reverse breakdown |

| |

| Use a capacitor with a breakdown voltage of 200 to 300 V. Use AC type capacitors | voltage of about 2 to 3 times the |

| |

|

| power supply voltage. |

| |

2.Type of Load and Inrush Current The type of load and its inrush current characteristics, together with the switch- ing frequency, are important factors which cause contact welding. Particularly for loads with inrush cur- rents, measure the steady state current and inrush current and use a relay or magnet switch which provides an ample margin of safety. The table below shows the relationship between typical loads and their inrush currents.

Type of load | Inrush current |

Resistive load | Steady state current |

Solenoid load | 10 to 20 times the steady state current |

Motor load | 5 to 10 times the steady state current |

Incandescent lamp load | 10 to 15 times the steady state current |

Mercury lamp load | 1 to 3 times the steady state current |

Sodium vapor lamp load | 1 to 3 times the steady state current |

Capacitive load | 20 to 40 times the steady state current |

Transformer load | 5 to 15 times the steady state current |

When you want large load and long life of the counter, do not control the load direct with a counter. When the counter is designed to use a relay or a magnet switch, you can acquire the longer life of the counter.

3.Connection of input (Except for LC4H-S/AC type)

The LC4H series use power supply with- out a transformer (power and input termi- nals are not insulated). In connecting

various kinds of input signals, therefore, use a power transformer in which the pri- mary side is separated from the ungrounded secondary side as shown in Fig. A, for the power supply for a sensor and other input devices so that

(Fig. A) Good

Insurating transformer

(+) | Input equipment |

(sensor, etc.) | |

| |

|

Counter

(Fig. B) No good |

|

AC power supply |

|

Insurating transformer |

|

(+) | Input equipment |

(sensor, etc.) | |

| |

| |

Counter |

|

AC power supply

Single coil transformer |

| |

(+) | Input equipment | |

| ||

(sensor, etc.) | ||

| ||

| ||

Counter | AC power | |

routing | ||

|

Do not use a single coil transformer (e.g.,

4.Long Continuous Current Flow Avoid keeping the counter on for a long period of time (over one month). Otherwise heat is generated and accu- mulated inside the counter, which may deteriorate its electronic parts. If the counter must be kept on for a long period of time, a relay is added. See the circuit diagram below.

R | C | R | R |

| R Relay | C Counter | Receive output |

| from contact | ||

|

|

| at relay R |

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net